Customized High-Precision Screws, Delivery Efficiency Increased By 30%。

we provide end-to-end solutions: From specialized screws (titanium/extra long/non-standard) to precision CNC machining, stamping parts, springs, and matching accessories (nuts/washers/rivets). Streamline your supply chain with vertically integrated production, export-ready quality, and 30% faster lead time.

- 24H Rapidly Quote

- ISO9001 Certified Quality

- One-Stop Fastener Solutions

Who We Are

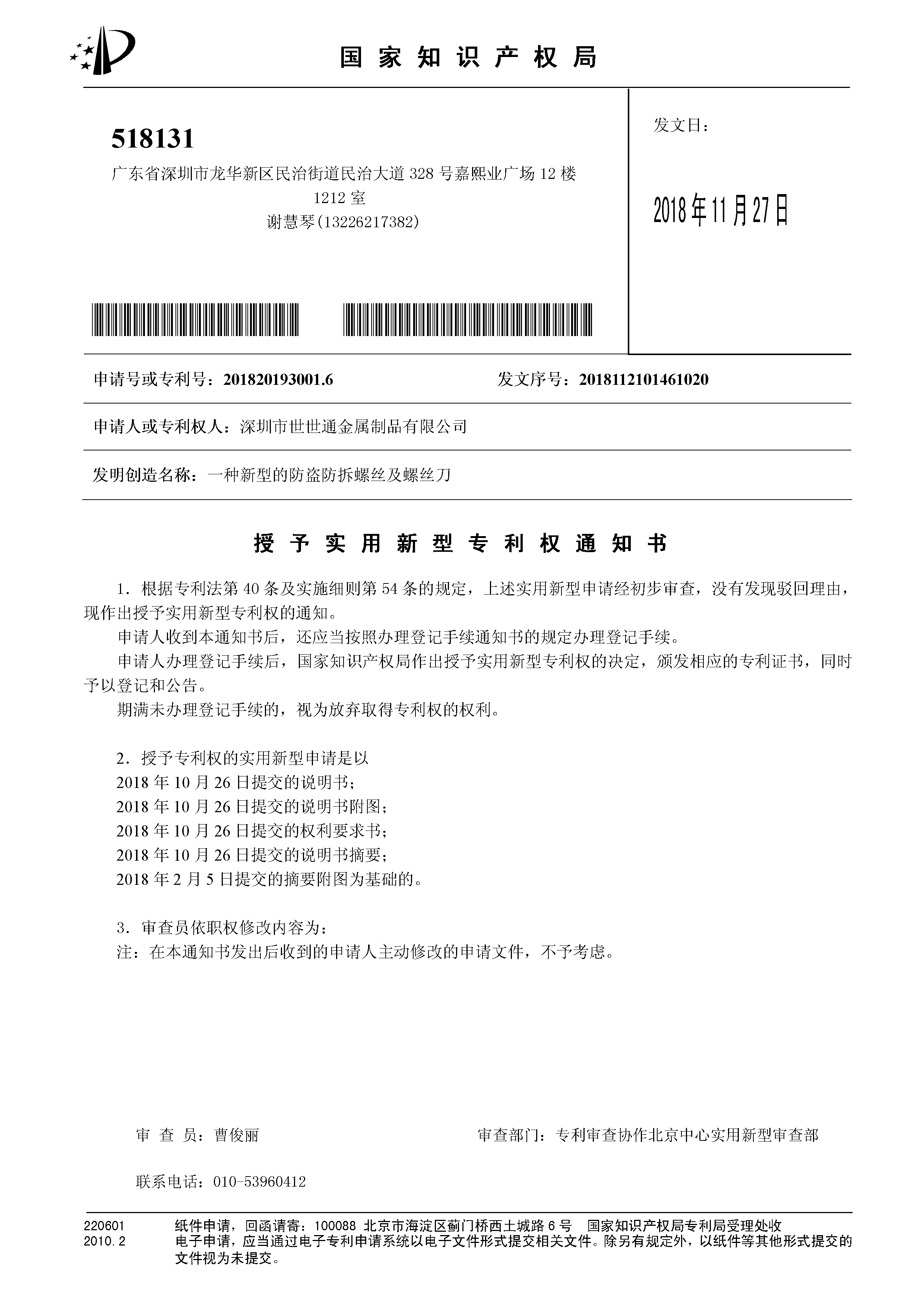

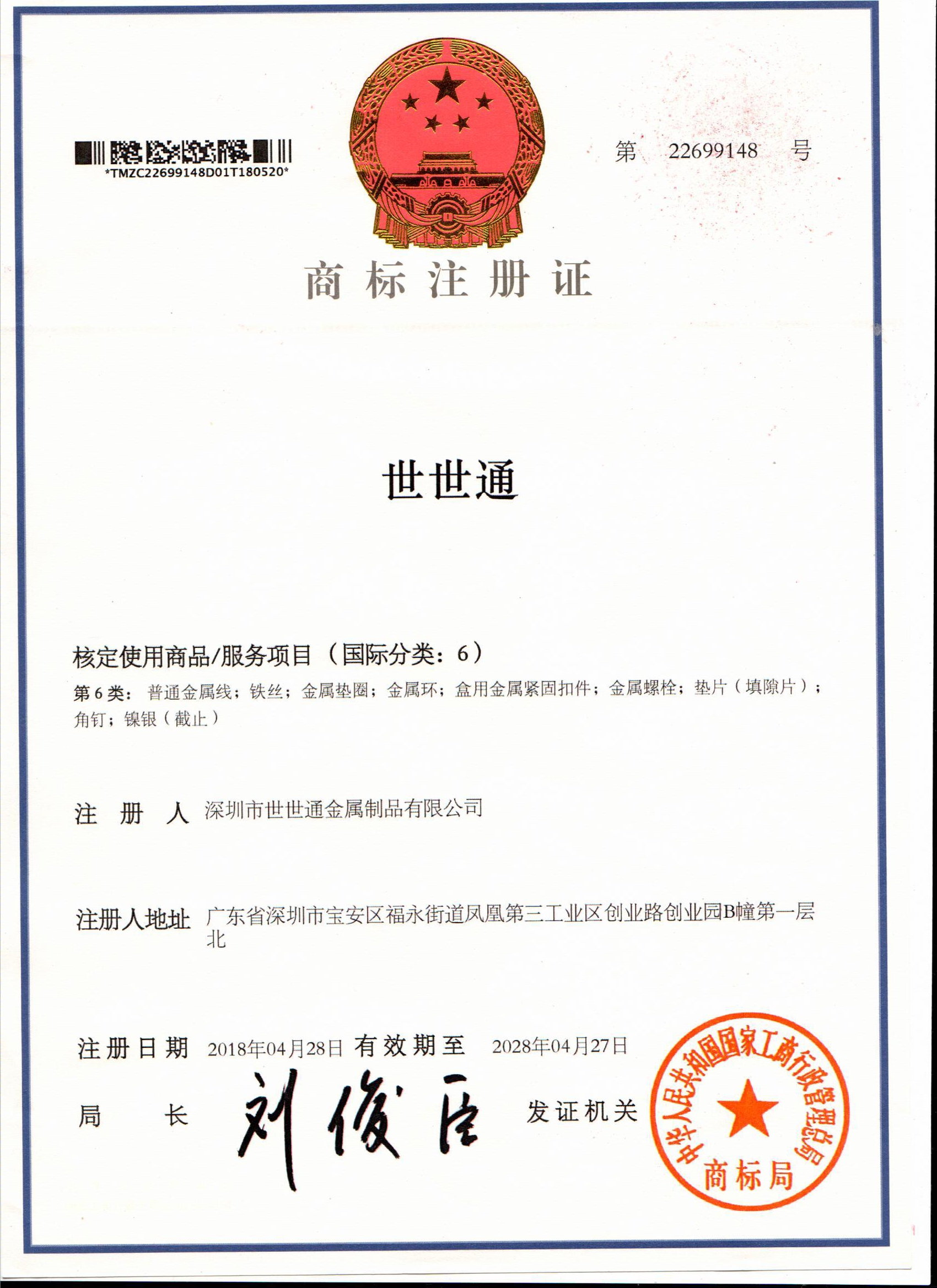

We are a company specializing in customized screws, to solve the global customer screw customization, design and production issues.

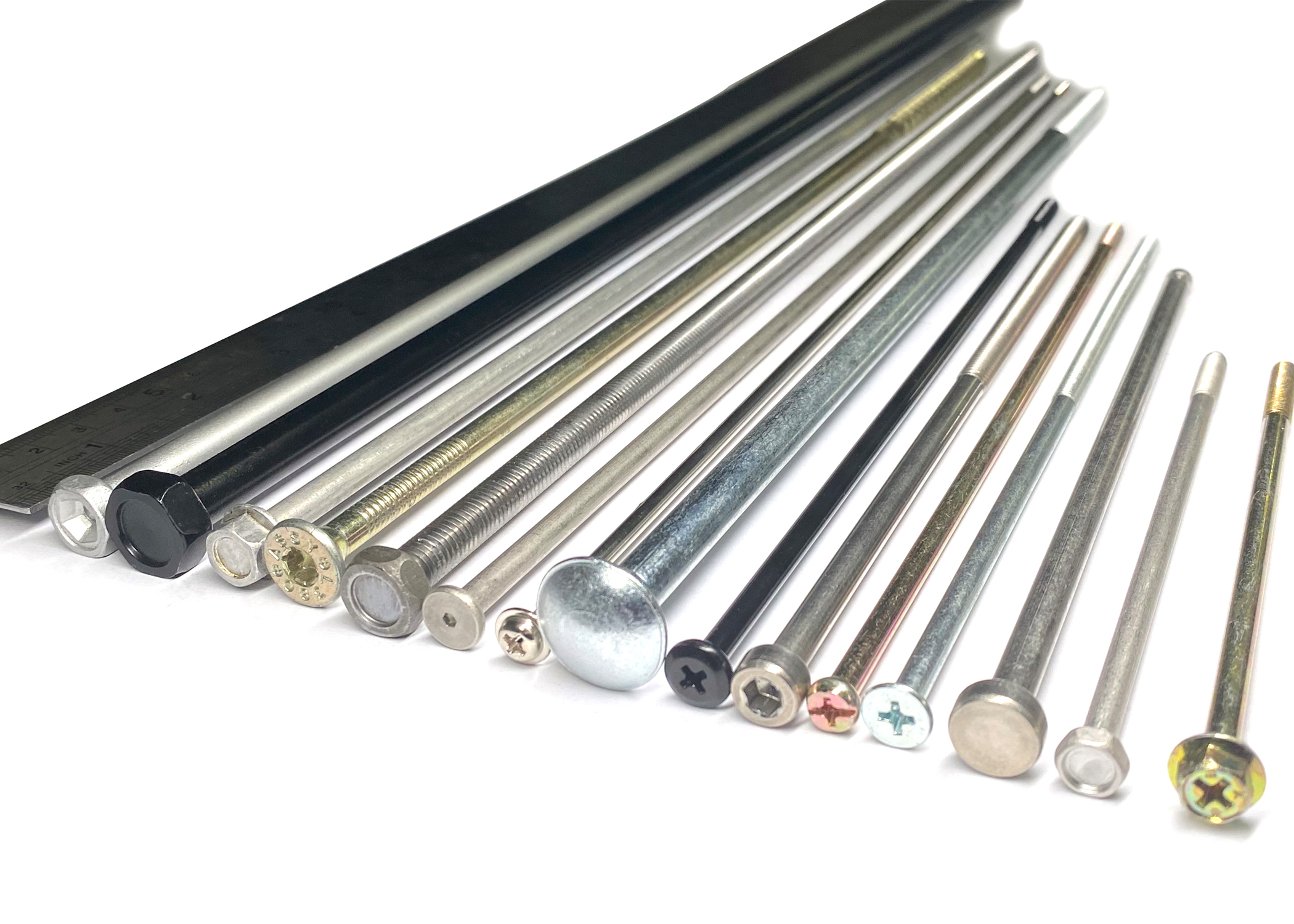

Mainly for: lengthening screws, non-standard special screws, titanium screws, precision small screws, step screws, CNC, precision spring parts and other fastener products customization.

Our manufacturing team has over 14 years experience on average. Our chief engineer has been developing and manufacturing screws for 36 years. We have independent import and export rights and take OEM and ODM orders.

Our main customer groups

Manufacturer

Engineer

Boss

Product Classification

Fastener-Related Products

Gaskets

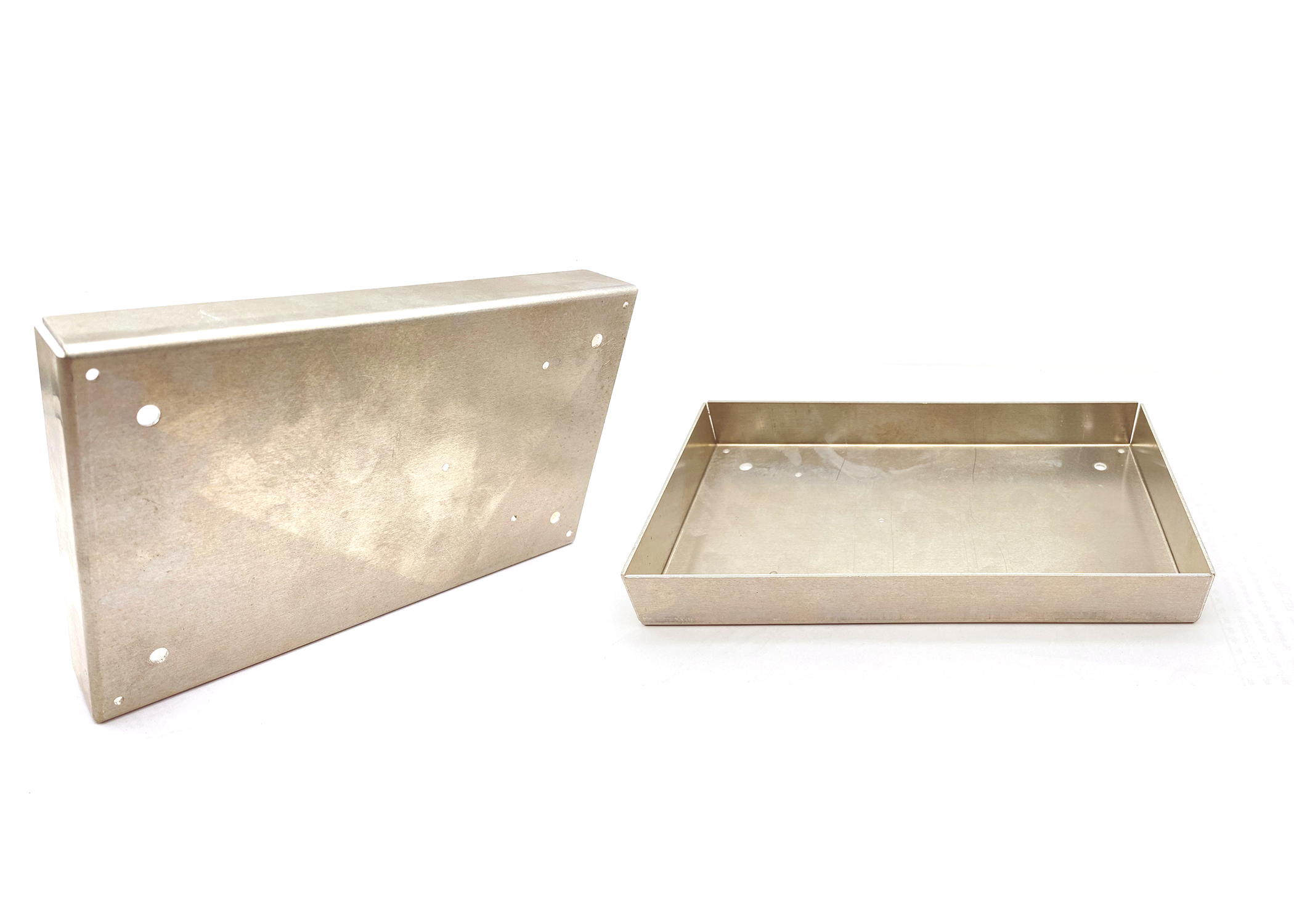

CNC Parts

Stamping Parts

Springs

Areas of application

Build Your Custom Solution in 3 Steps

1. Select Your Groove Type

We have 28 groove types for you to choose .

2. Choose Tooth Type

We have 24 tooth types for you to choose .

3. Design Your Head Shape

We have 21 types of teeth for you to choose .

Precision Fastening Solutions

1-Hour Quotes, 72h Prototypes, ISO-Certified.

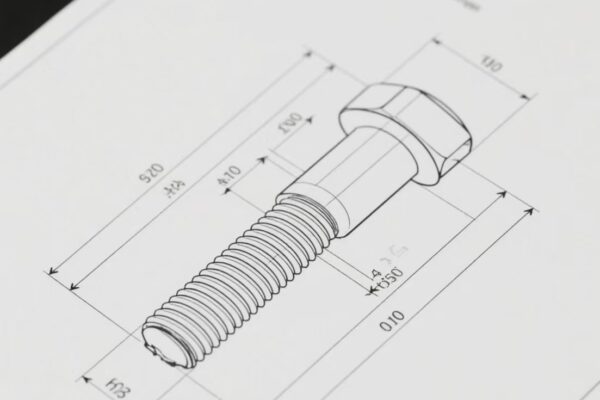

1.Upload Drawing

Submit CAD/PDF drawings or send samples online.

2. Your request

Shape, material, surface finish, quantity, size。

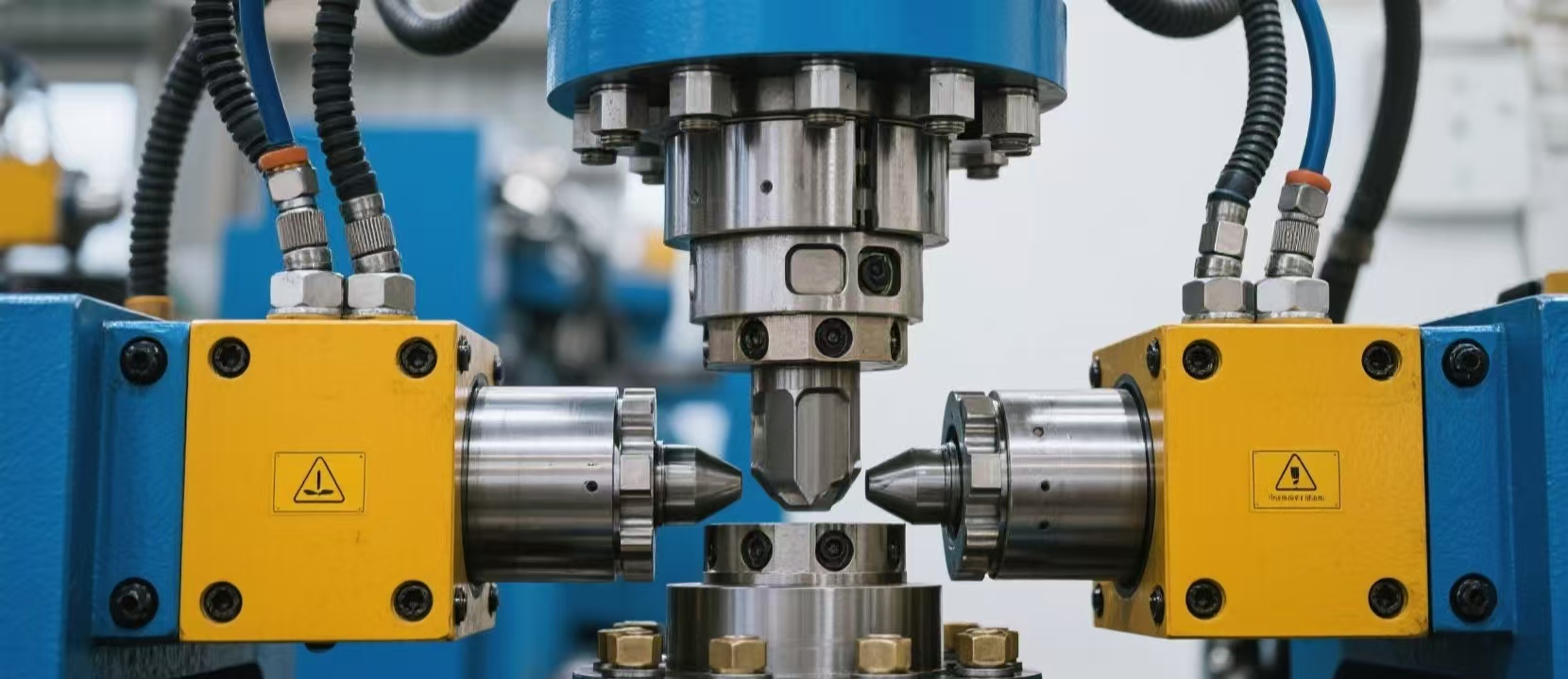

3. Rapid Prototyping

CNC precision machining + 3D printing synchronous start-up, 72 hours to deliver functional samples。

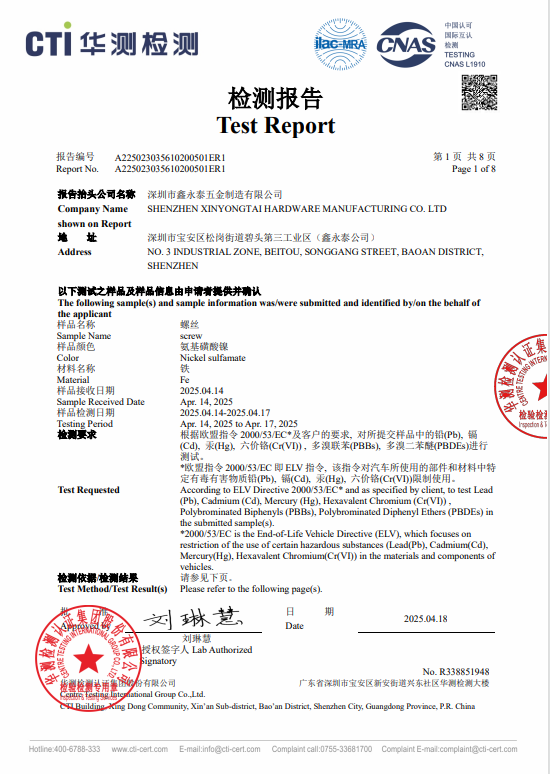

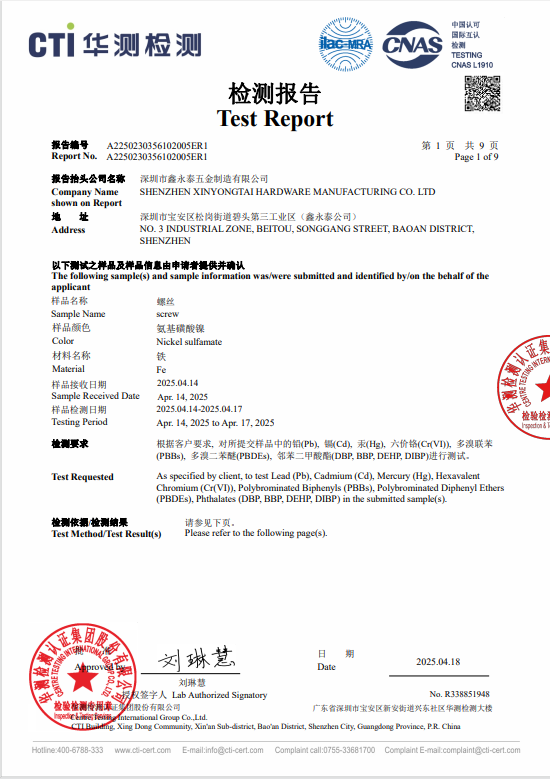

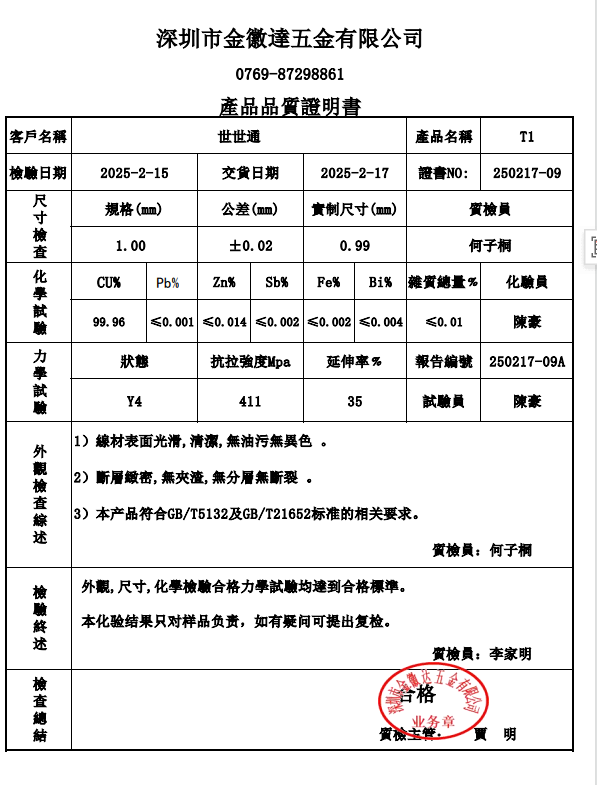

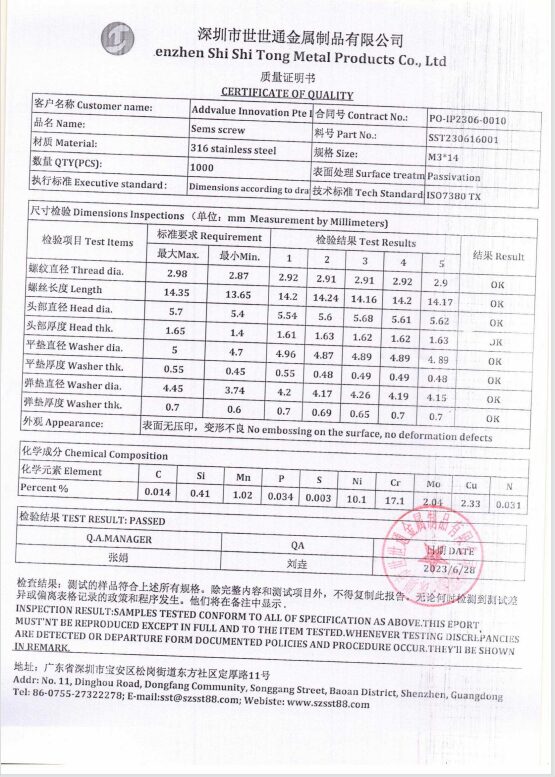

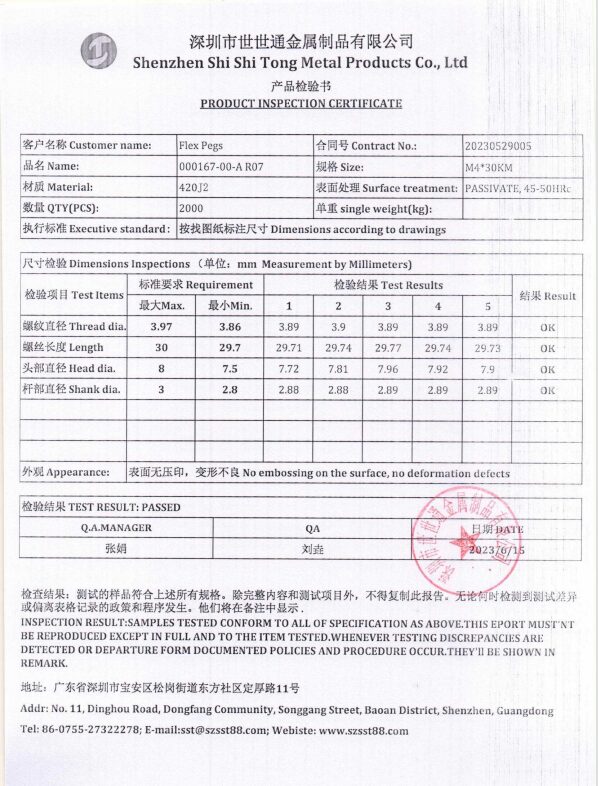

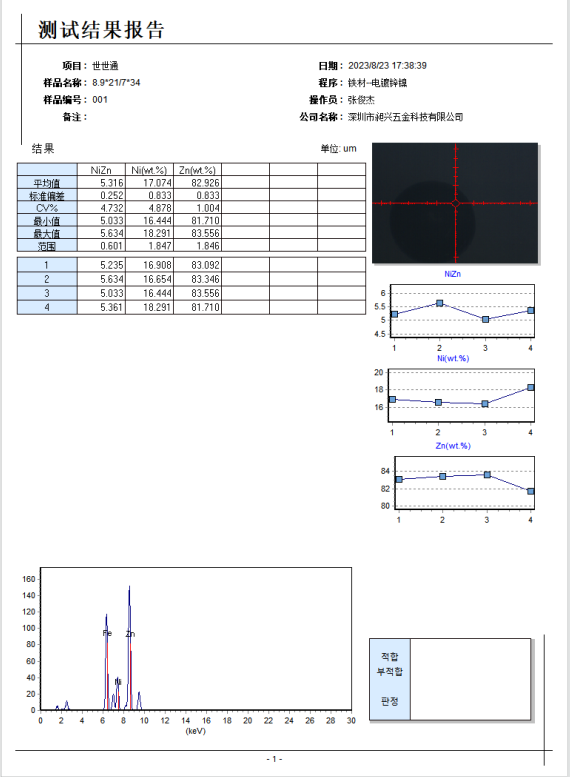

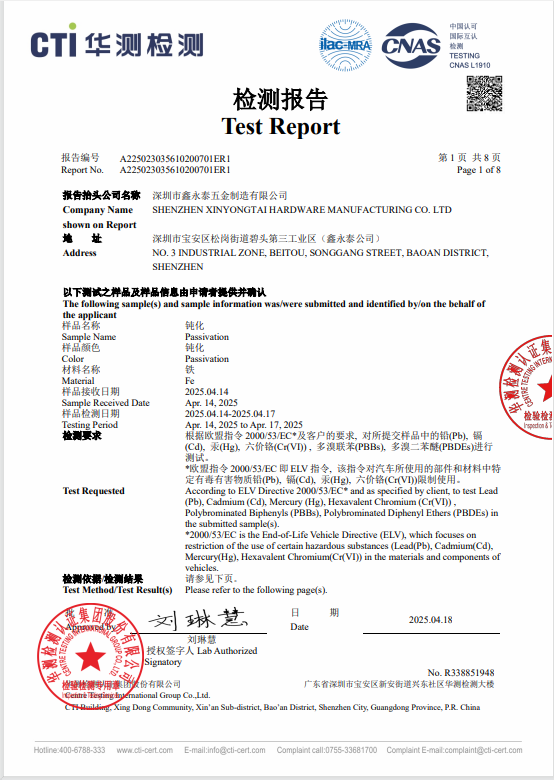

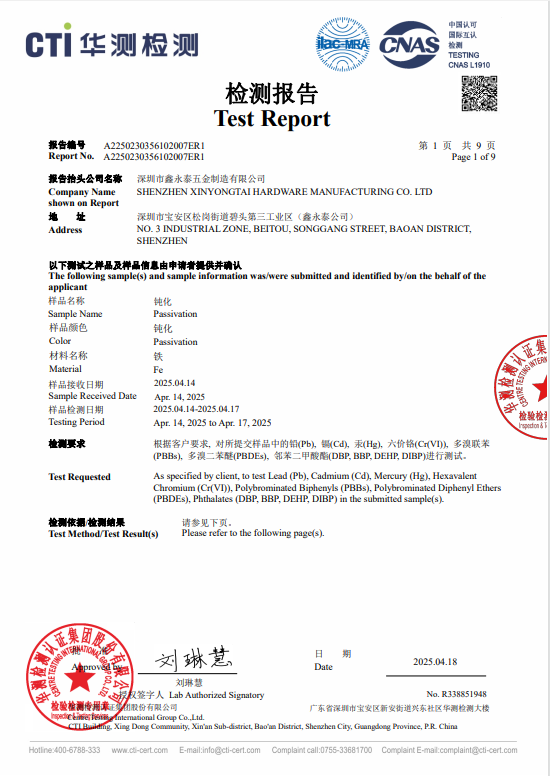

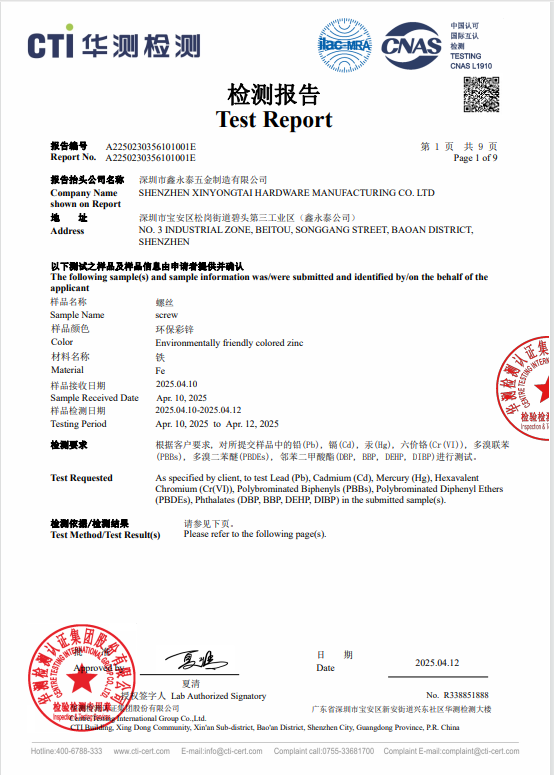

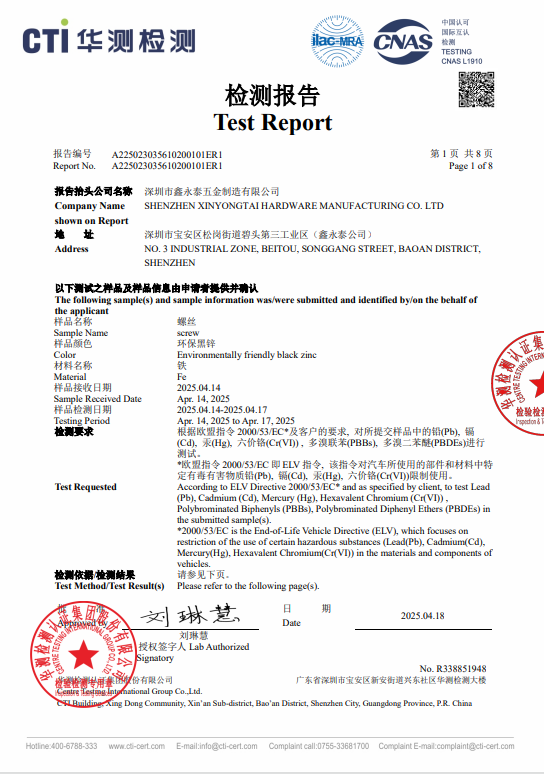

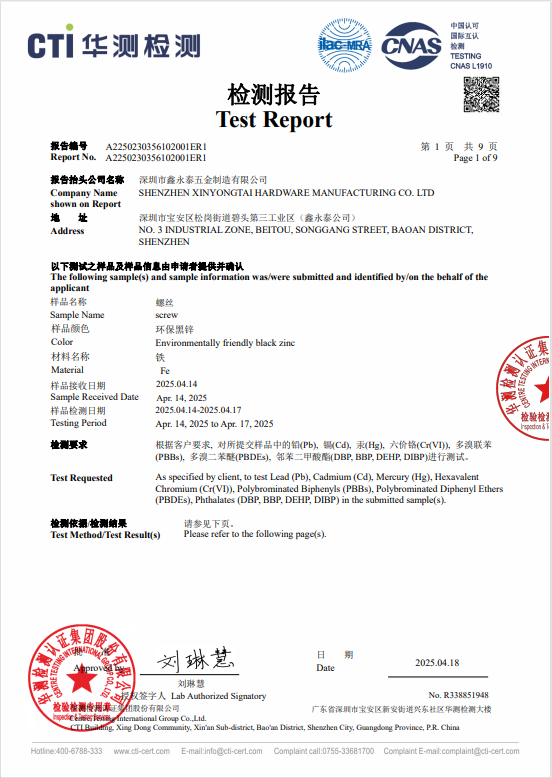

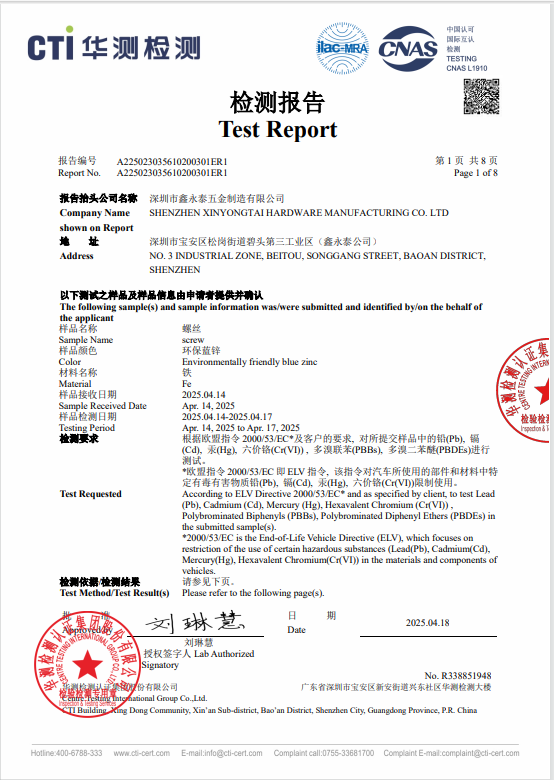

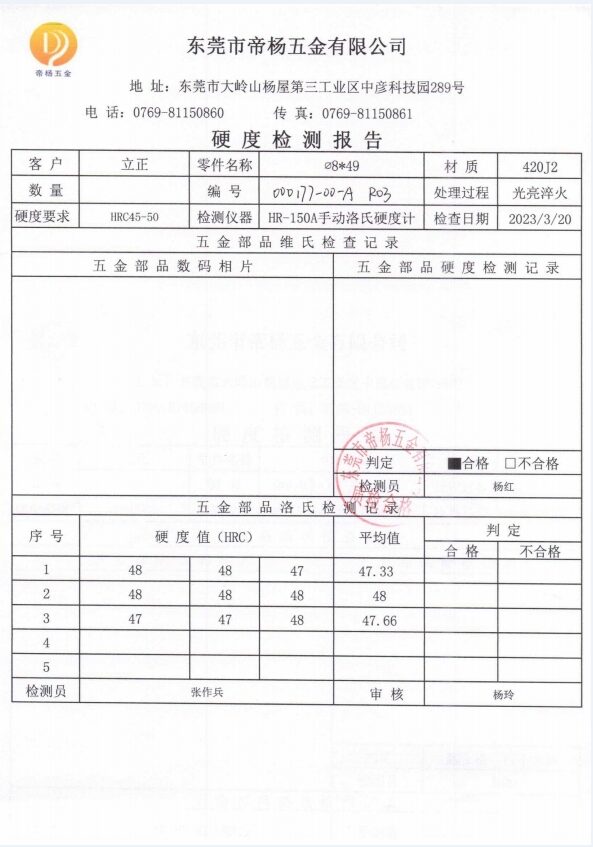

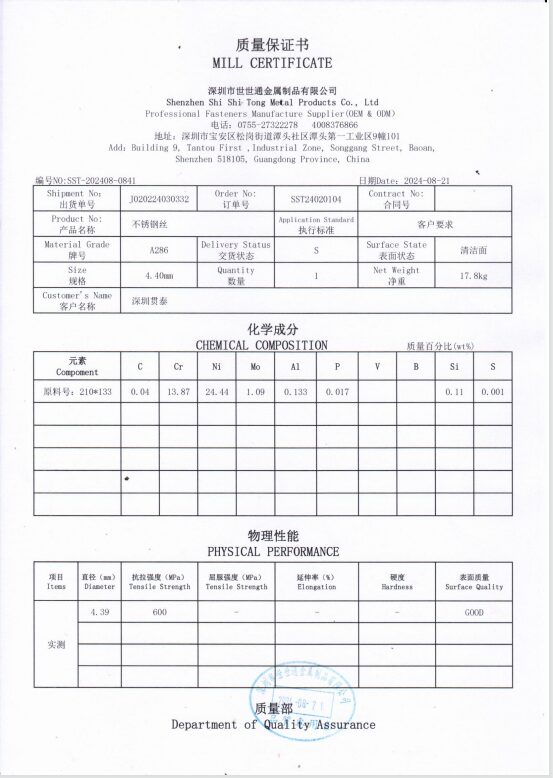

4. Provide a report

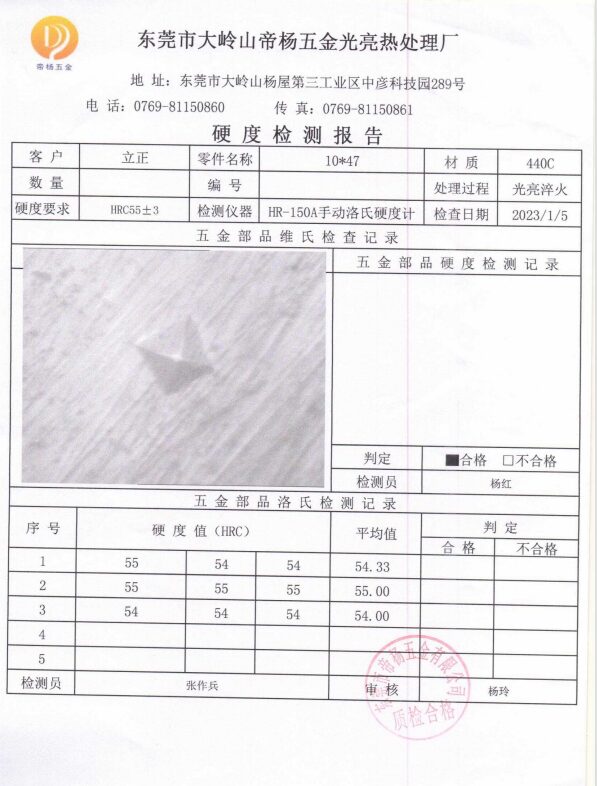

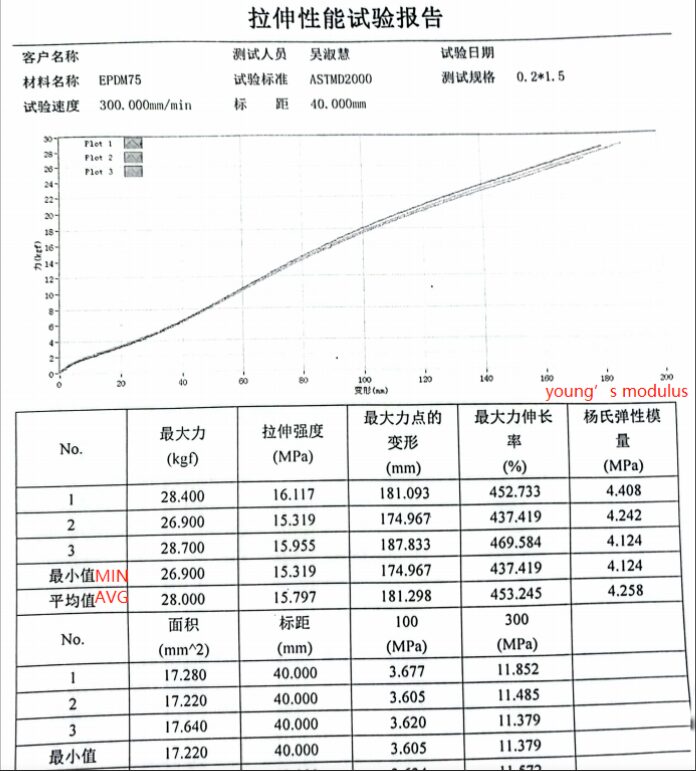

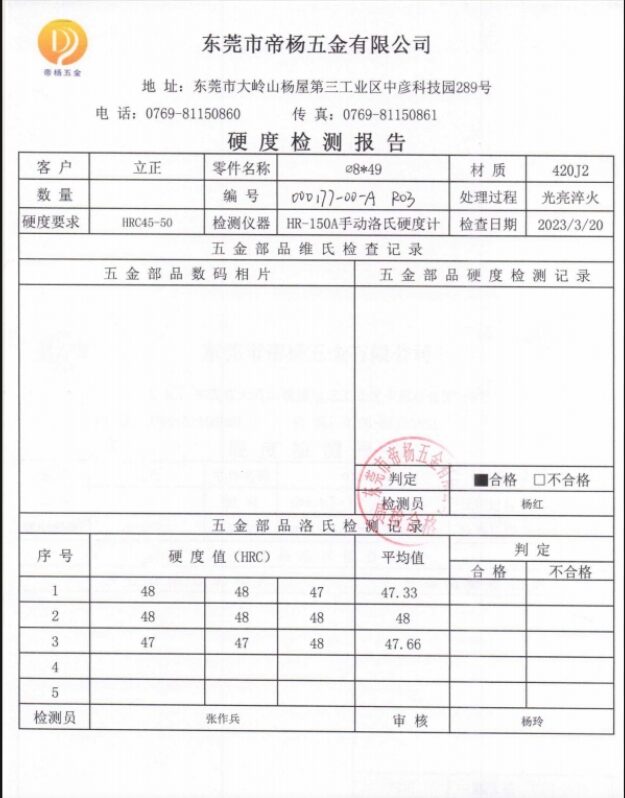

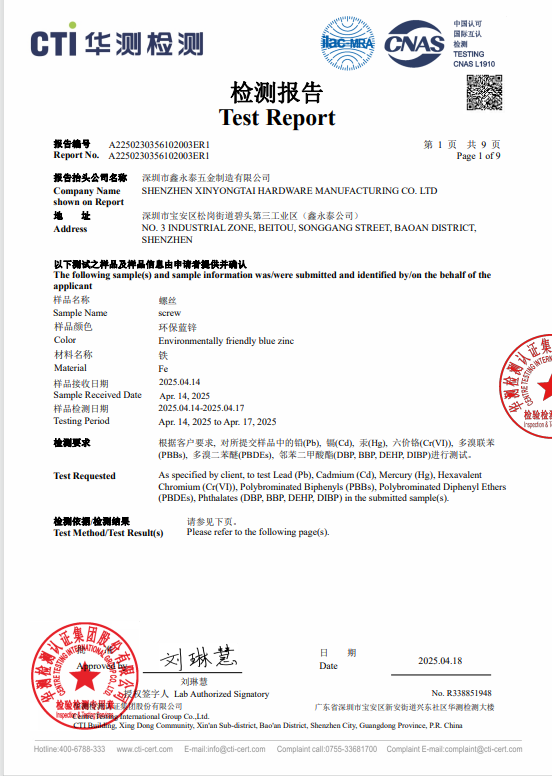

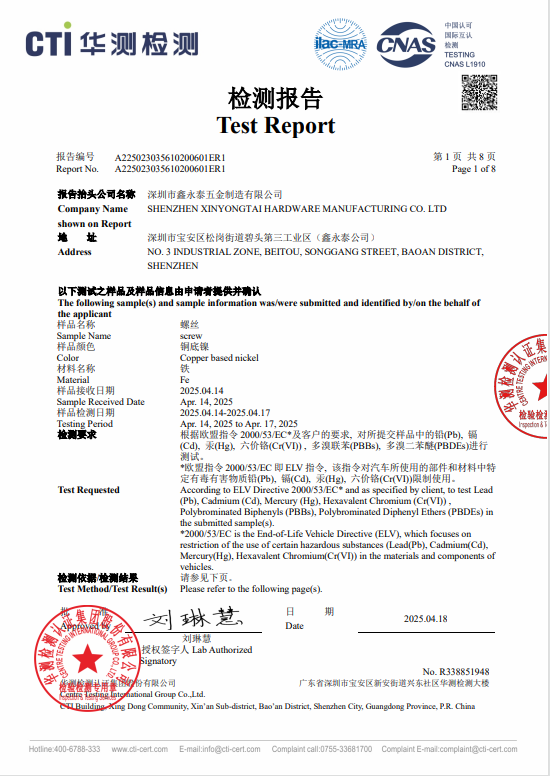

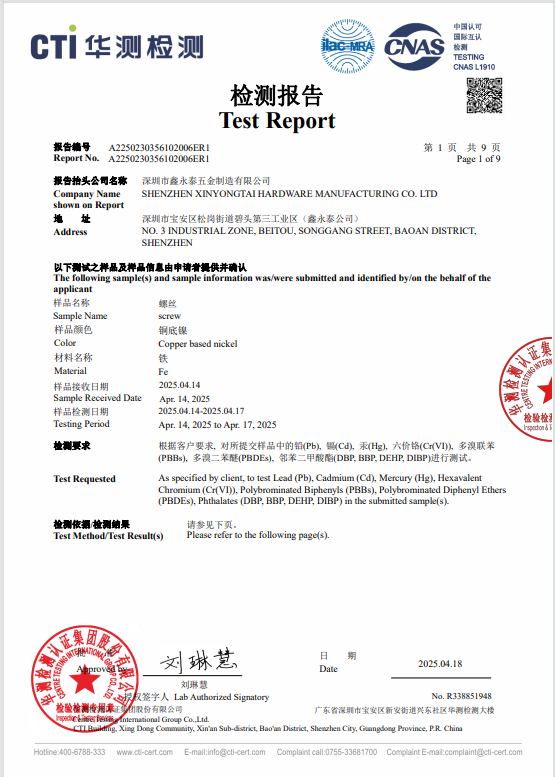

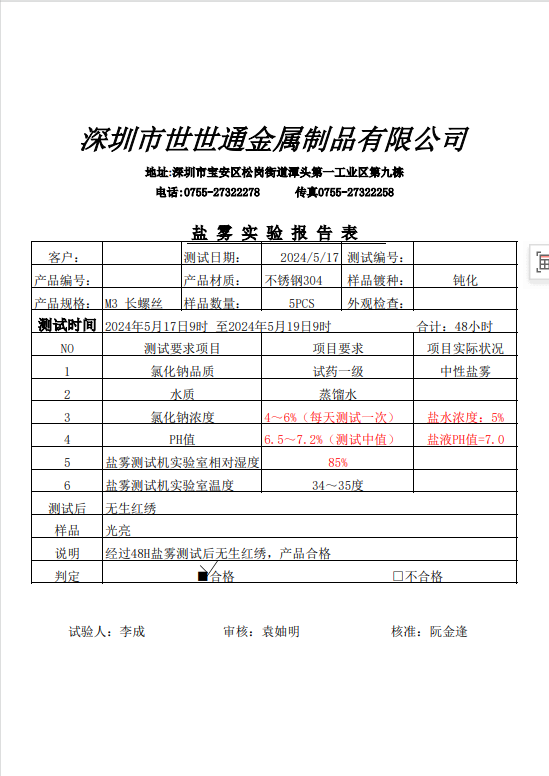

To provide you with a customized product inspection report and production cost forecast.

5. Mass Production & QC

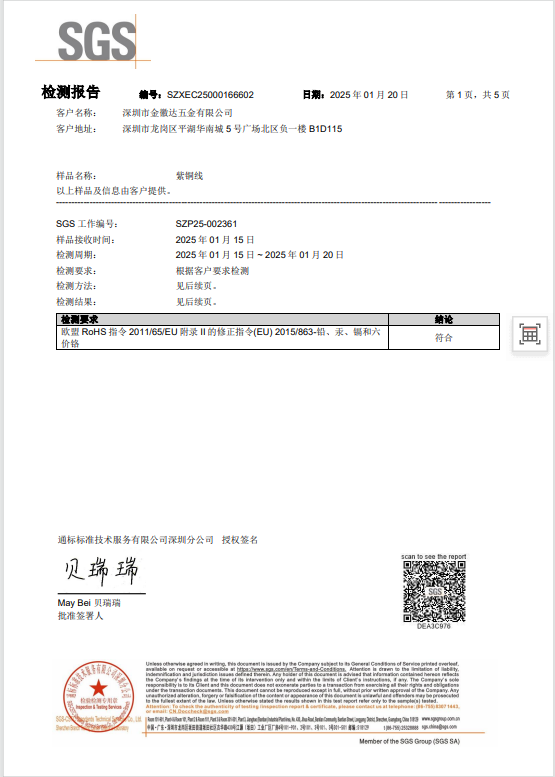

The whole process of digital production, every 500 pieces of full inspection once, support SGS third-party inspection, 7-15 days to complete order delivery.

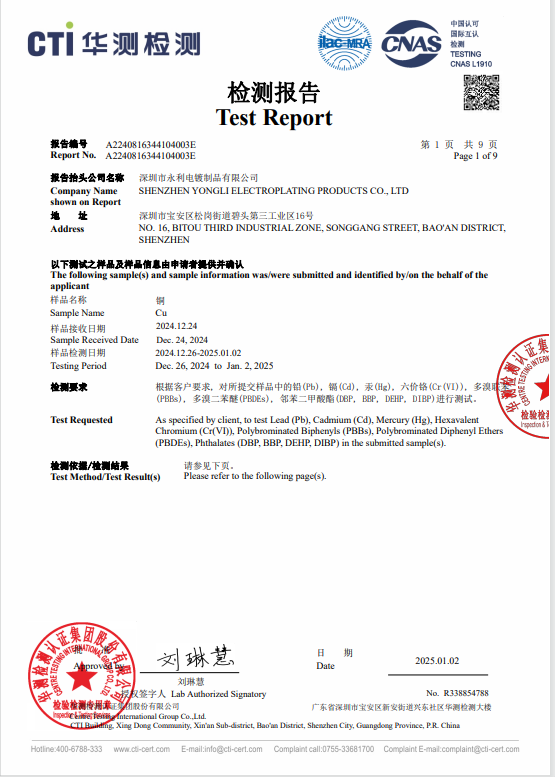

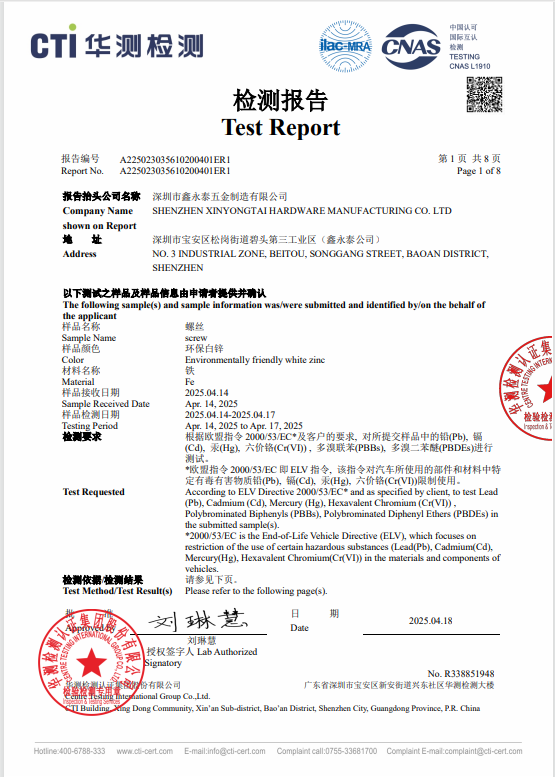

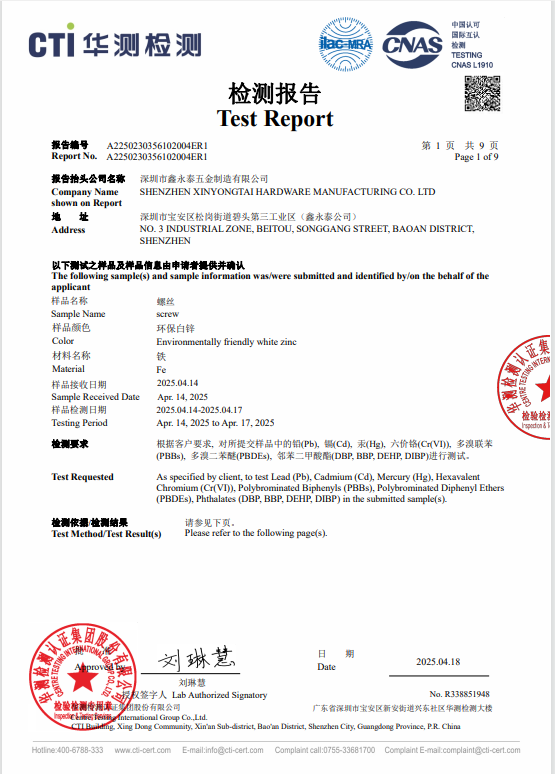

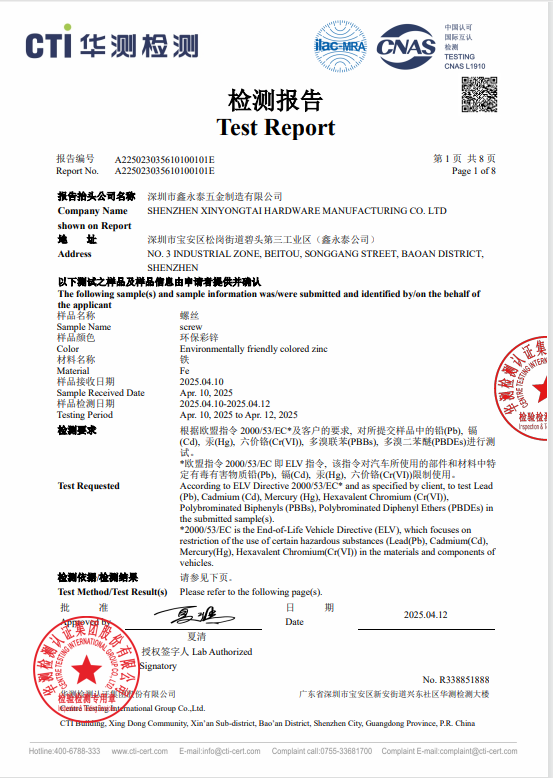

Our Survey Report

Our Clients:

What Our Clients Say

From M0.8 micro-parts to military grade titanium alloy, 25 years of experience in customized expert-6800 + enterprise verificationZero error delivery commitment, new energy/medical/aerospace customers repurchase rate of more than 83% .

Let the professional team escort your design

Submit your requirements →10-minute top rapidly quotes →36 years experience in team escort production