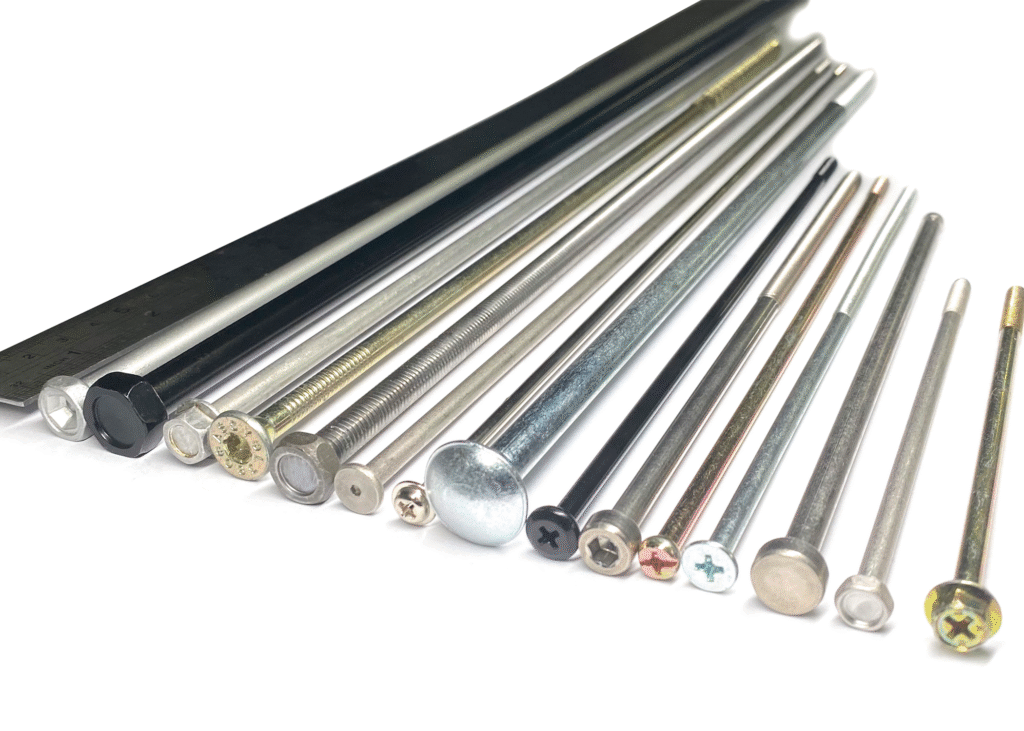

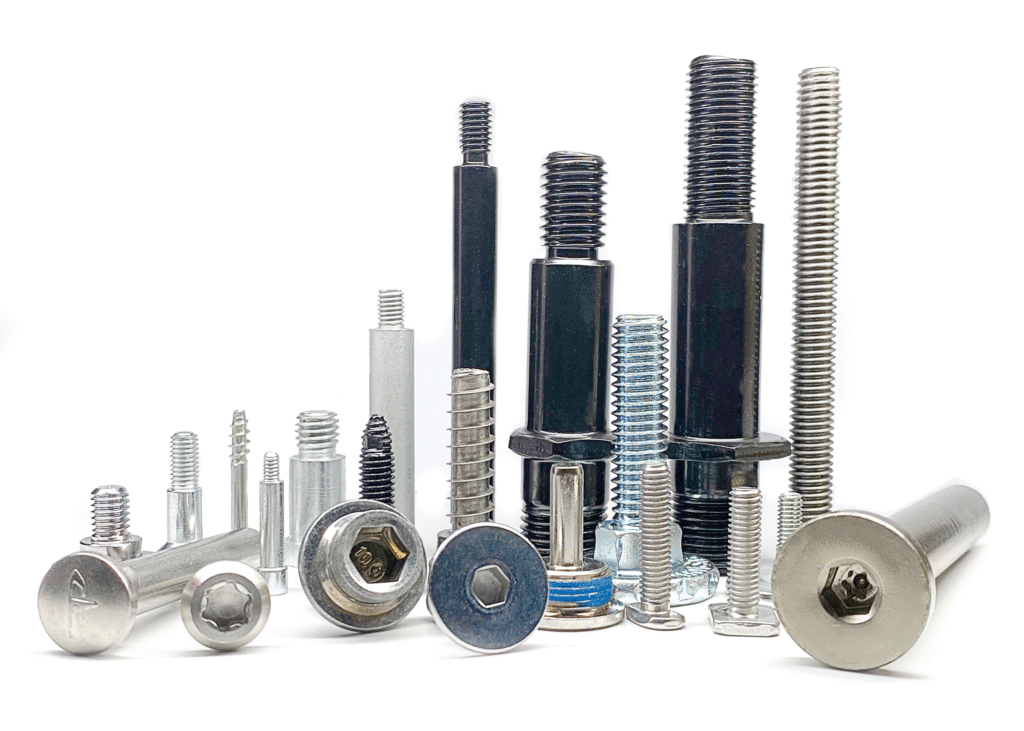

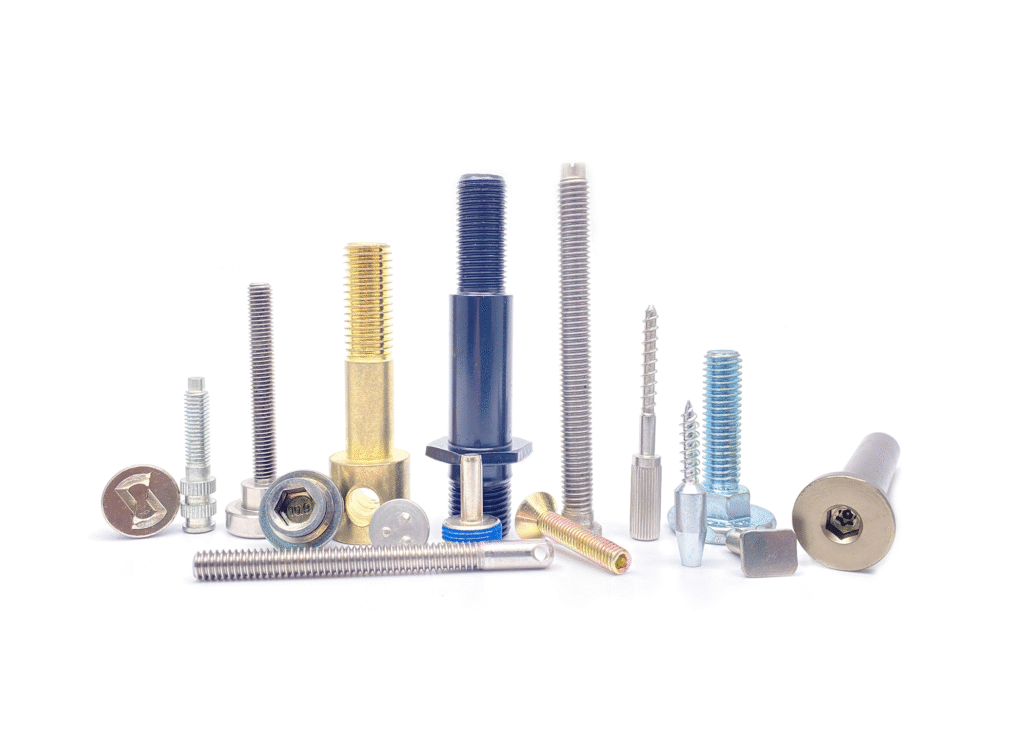

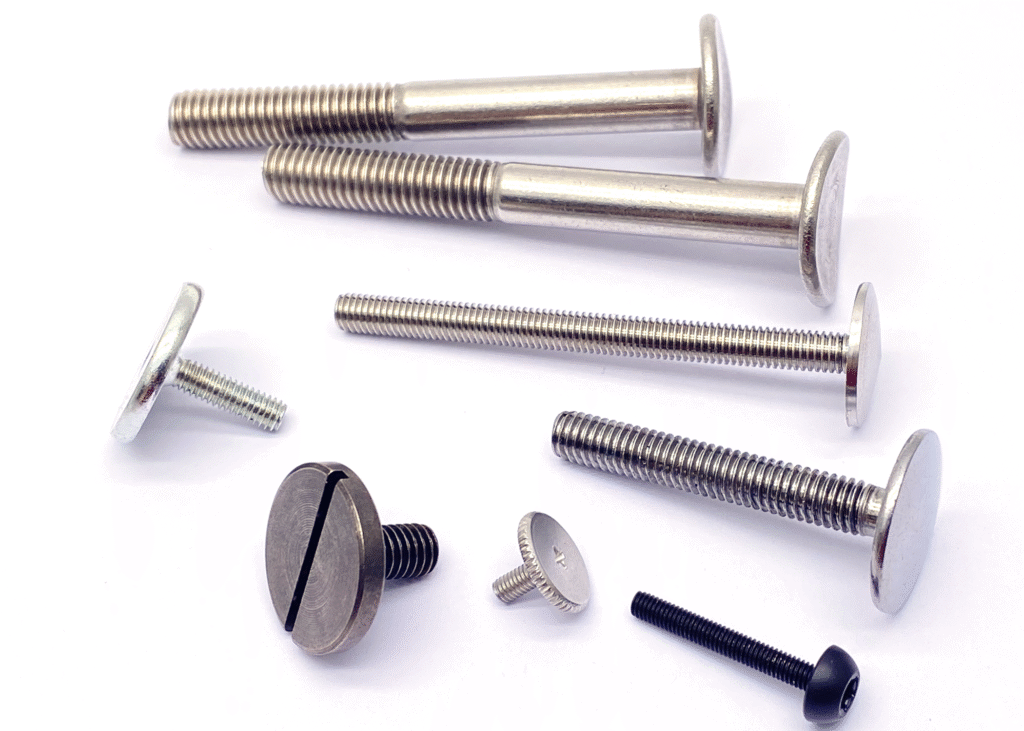

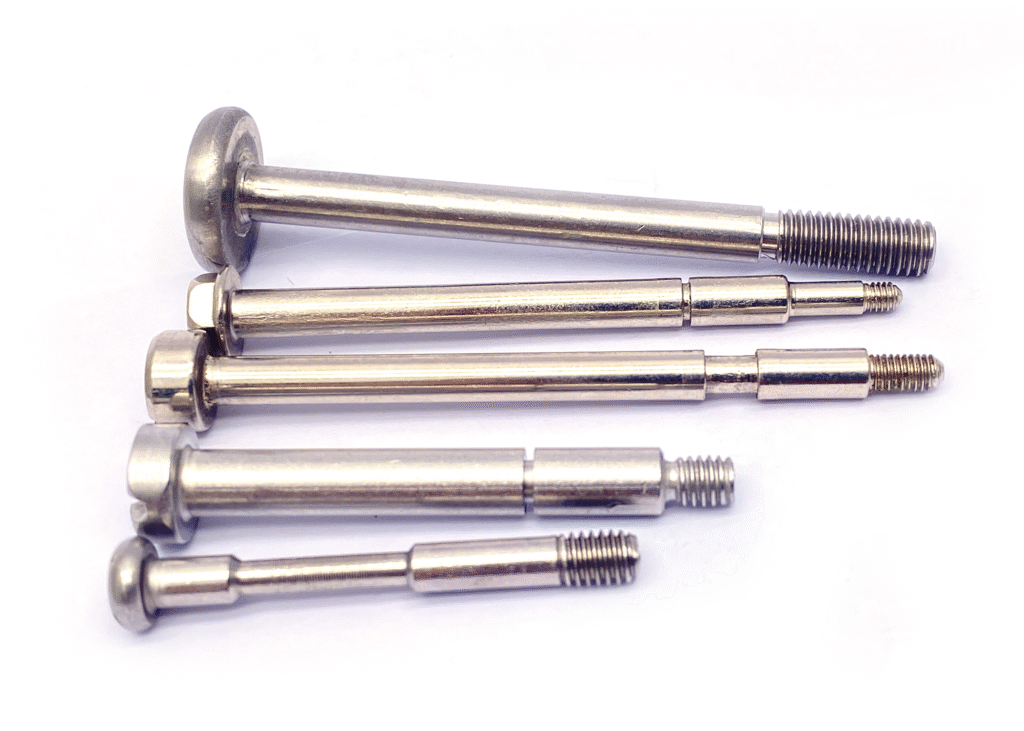

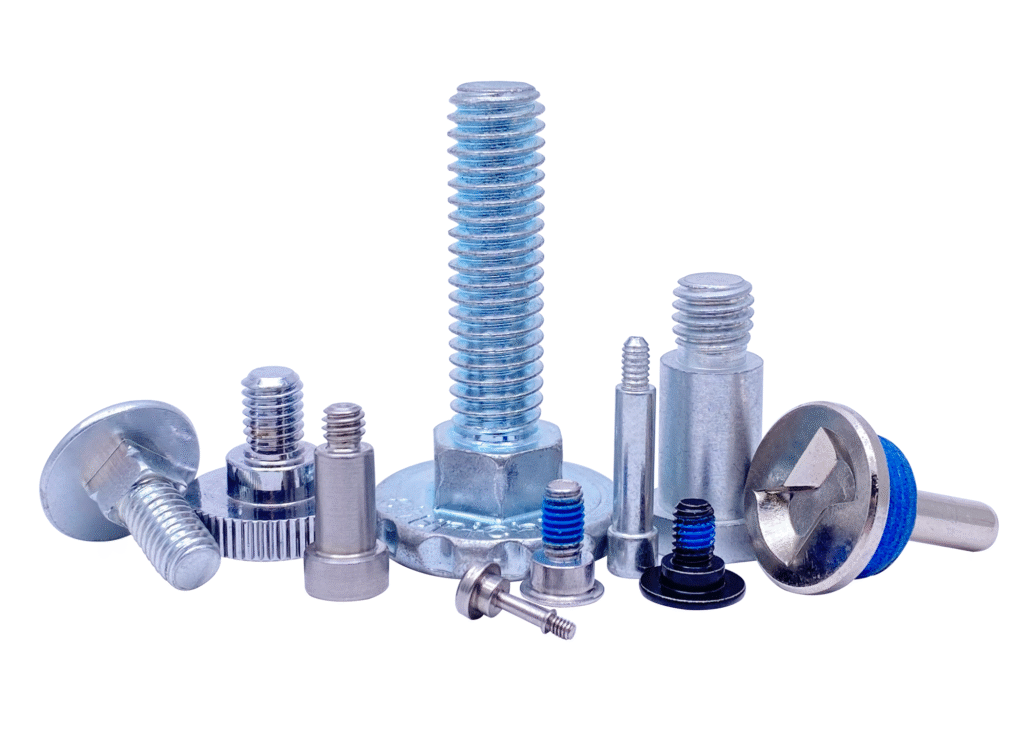

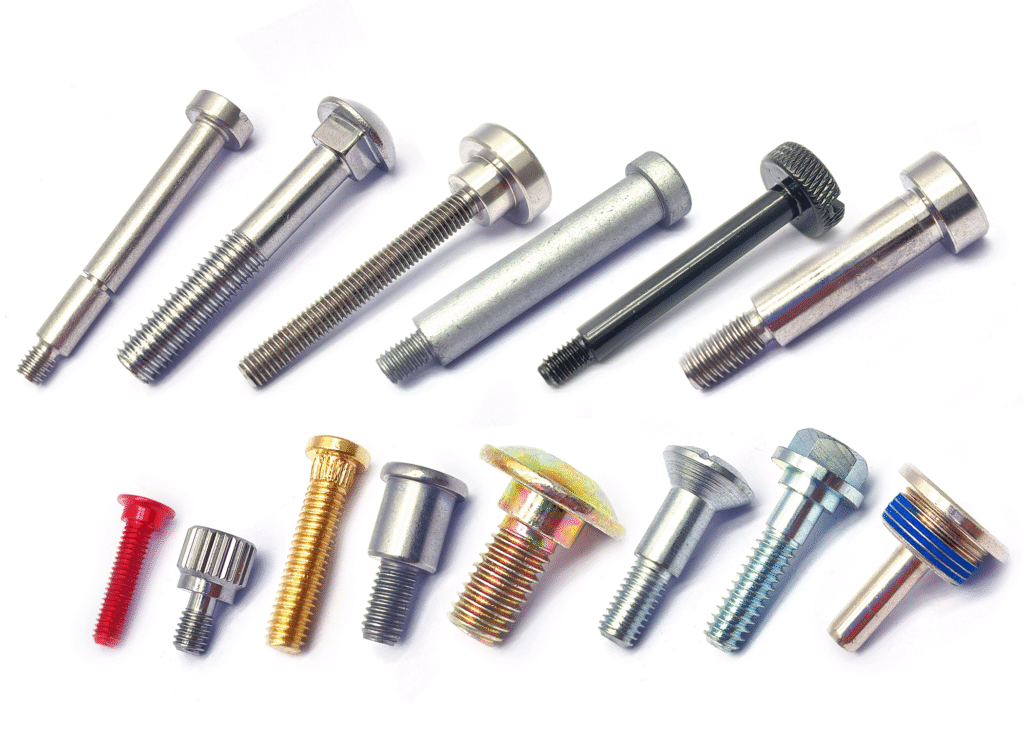

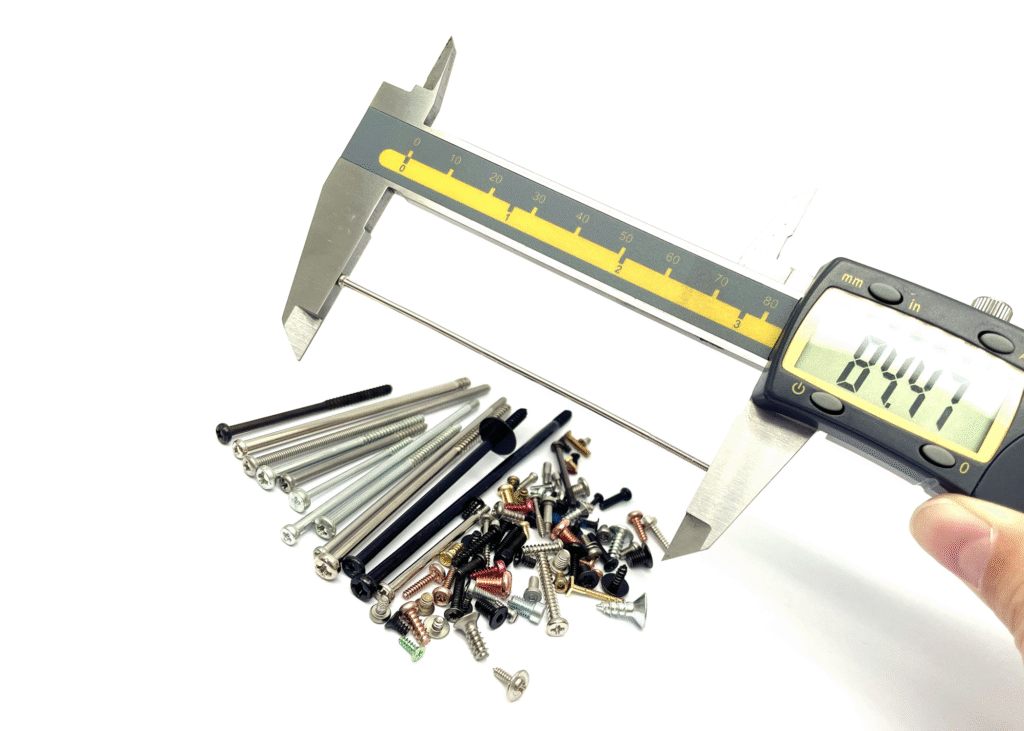

Screws

Discover Precision Screws for Every Application. SST Fasteners offers an extensive range of high-quality machine screws, self-tapping screws, thread-forming screws & specialty screws. Find reliable fastening solutions for industry & DIY.

How to select the screws?

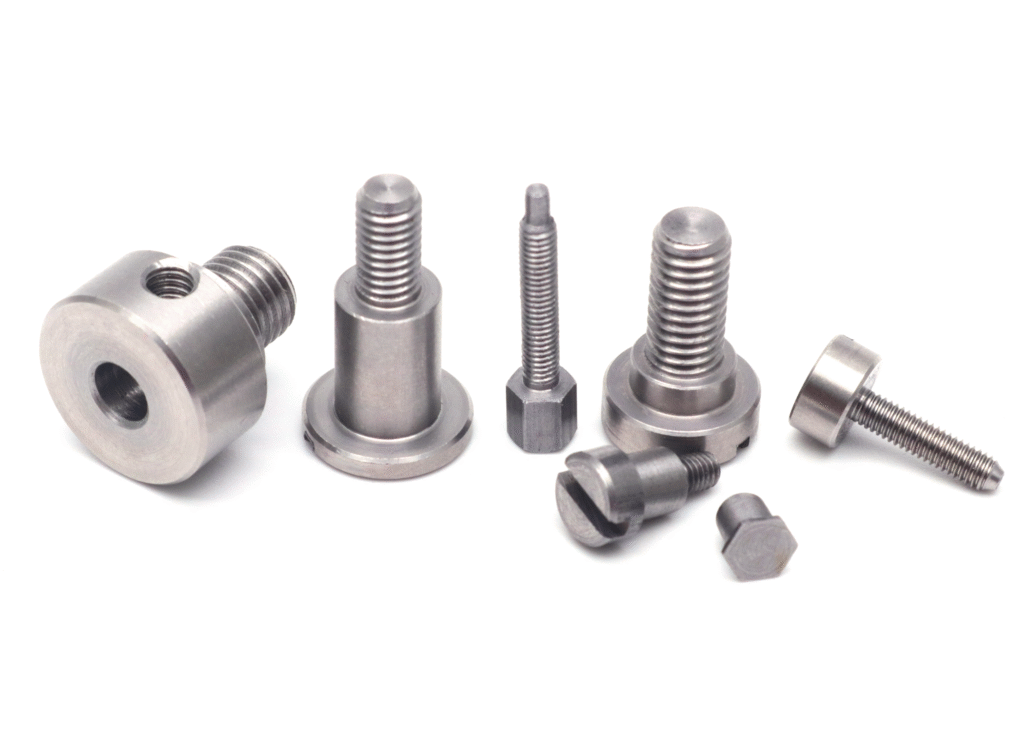

Type: Hexagon Head Screw, flange screw, countersunk head screw

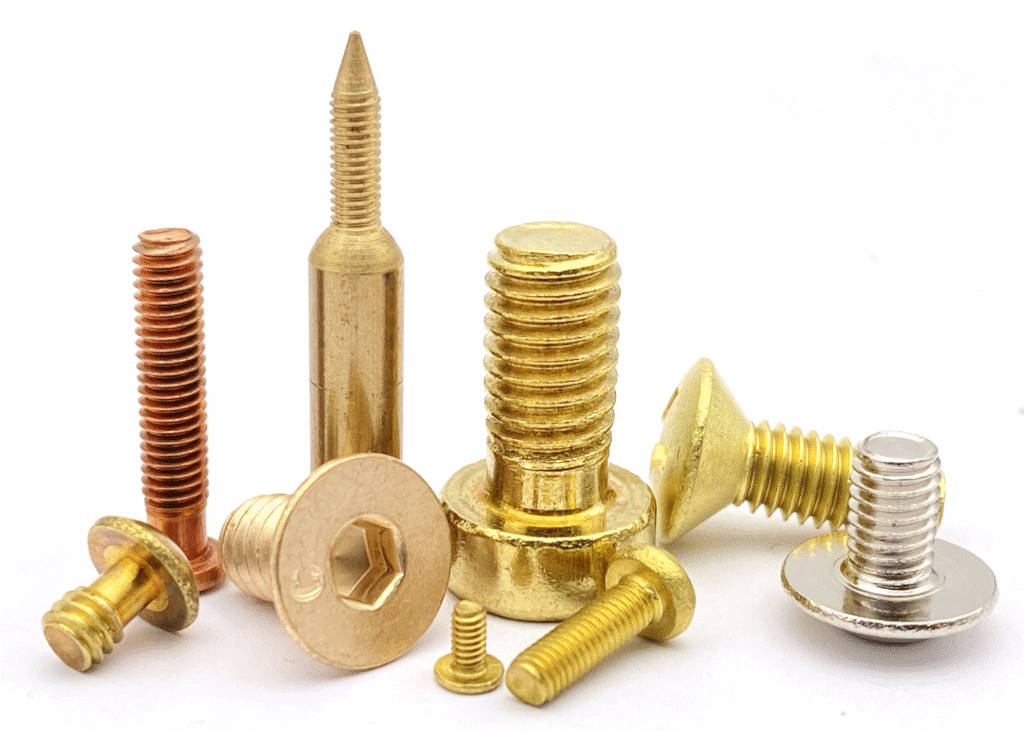

Texture:GH4169/Inconel 718/GH4145

Scene: aero-engine, gas turbine, nuclear power plant

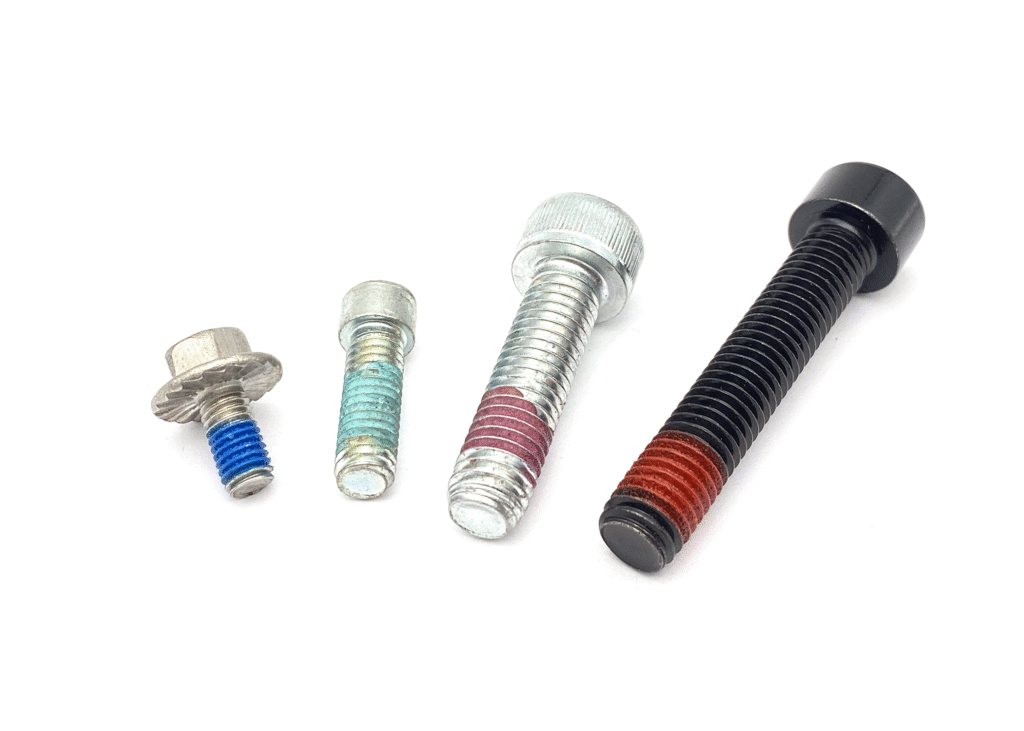

Type:self-tapping screws, rivet screws, miniature screws

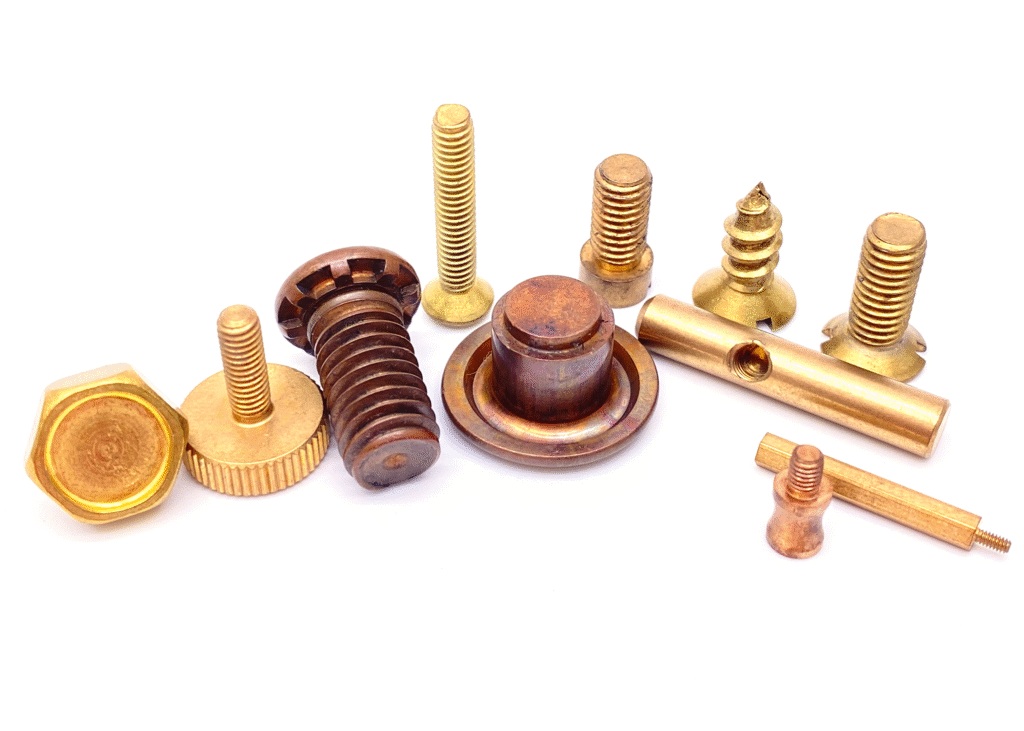

Material:Monel K500/Hastelloy/Inconel 625

Scenario:Chemical Pipeline, offshore platform, desalination plant

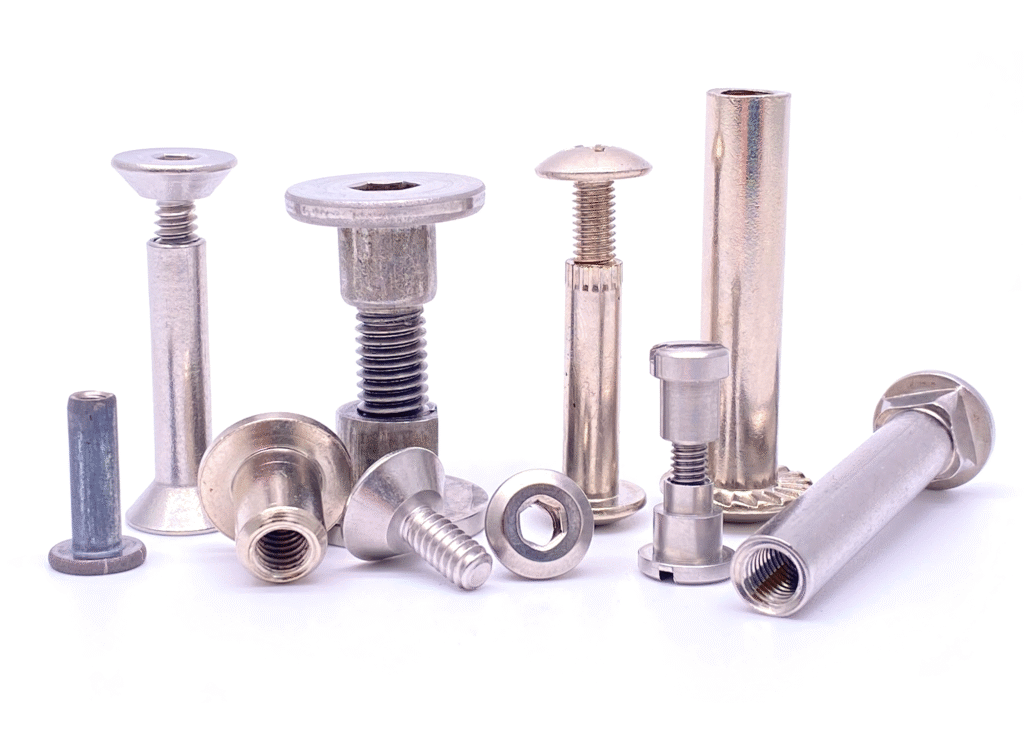

Type: miniature screws (M1-M3) , non-standard screws

Material:4J36/1J50/oxygen-free copper

Scenario:semiconductor devices, optical instruments, vacuum seal assemblies

Why our alloy screws?

Material type | Core performance | Scenarios | Comparative advantage of competitive products |

Superalloy | 800 °C heat resistance | Aero-engine fasteners | 5 times longer than 304 stainless steel |

Monel | Seawater corrosion resistance + high ductility | Ship and ocean engineering | Cost 30% less than titanium |

Soft magnetic alloys | High permeability and low loss | Precision electromagnetic equipment | Customizable zero hysteresis effect |

Build Your Custom Solution in 3 Steps

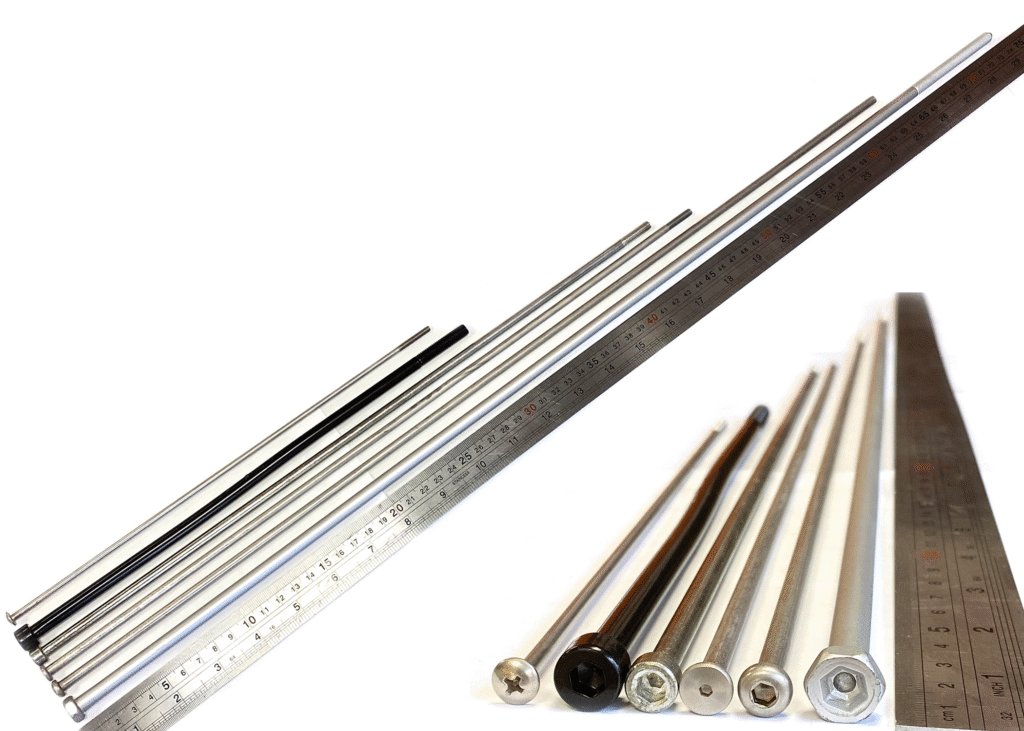

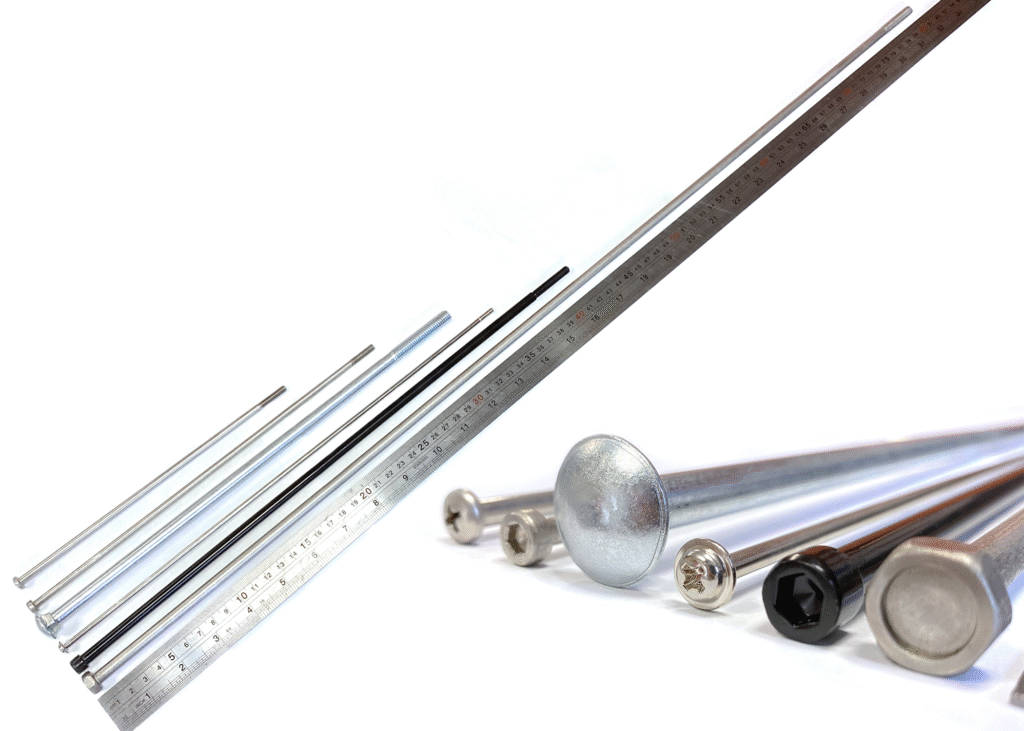

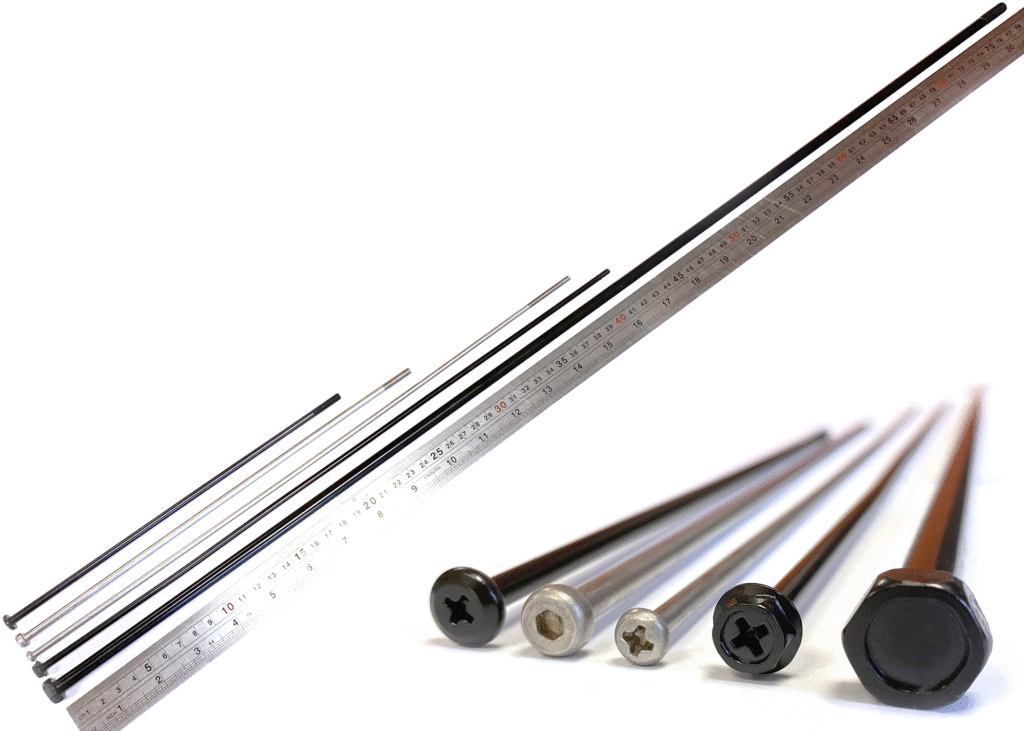

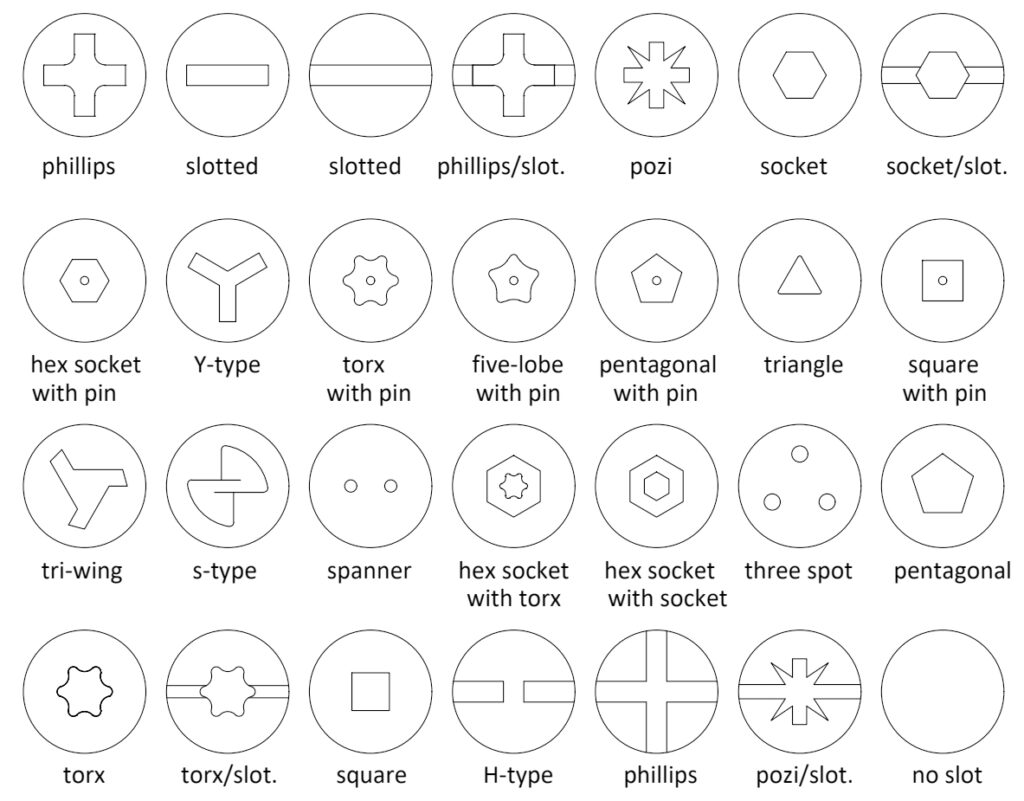

1. Select Your Groove Type – Optimize for Strength or Flexibility

Choose from 10+ engineered groove profiles – from standard V-grooves for general applications to specialized T-slots for heavy machinery.

Our CNC machining ensures ±0.005mm tolerance for perfect load distribution.

Pro Tip: 90% of industrial clients select helical grooves for vibration resistance.

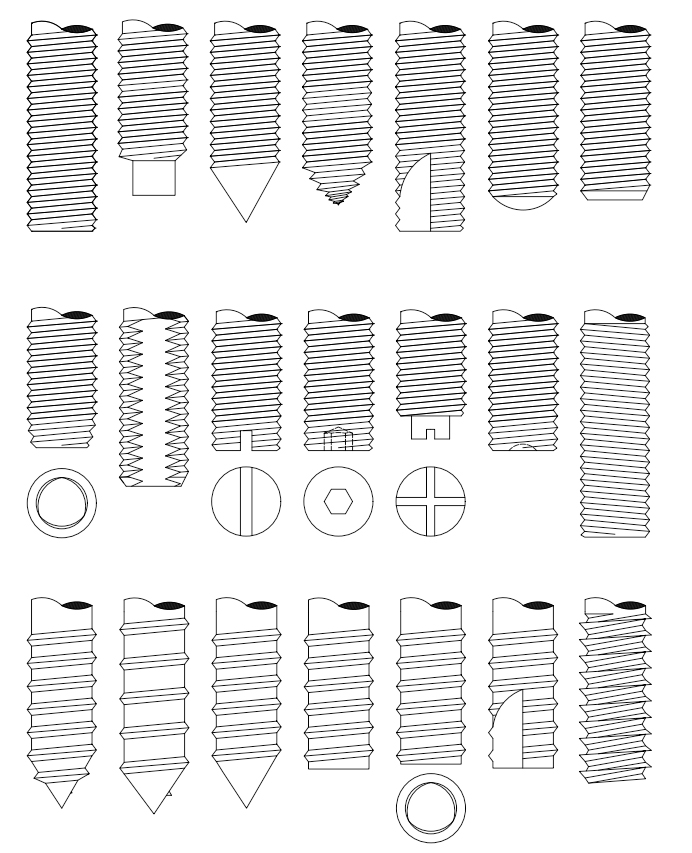

2. Choose Tooth Type: Precision Cutting or Smooth Engagement

Select triangular teeth for high-speed cutting (ideal for aerospace alloys)or rounded teeth to reduce wear in repetitive assembly (common in automotive).

Custom tooth pitch options available – Our engineers recommend 2.5mm pitch for 80% of polymer applications.

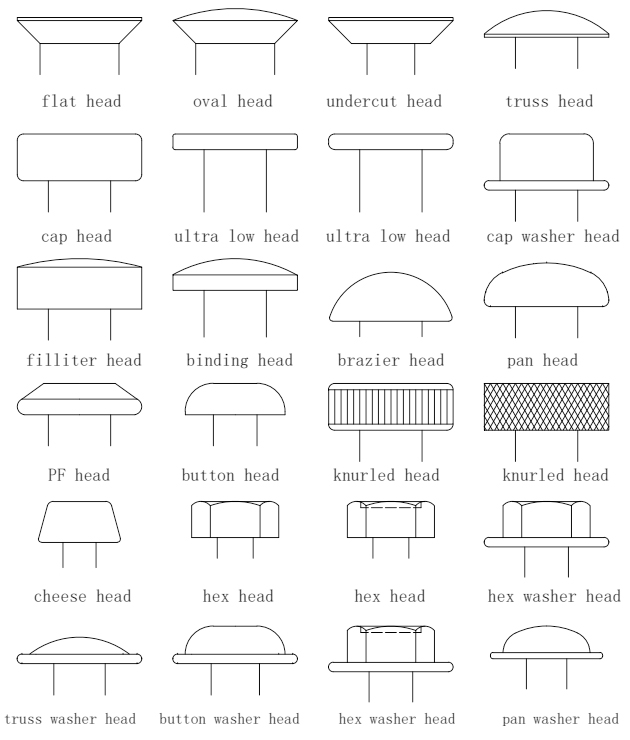

3. Design Your Head Shape: Functional Aesthetics Meets Installation Efficiency

From low-profile hex heads (ISO 4762) to tamper-resistant Torx designs, select shapes that align with your tooling ecosystem.

Pro Tip: 70% of clients pairing button heads with recessed grooves reduce installation time by 40%.

Precision-engineered from concept to delivery: Streamlined 5-stage process with 1-hour response, 72h prototyping, and ISO-certified quality control.

1.Upload Drawing

Submit CAD/PDF drawings or send samples online.

2. Your request

Shape, material, surface finish, quantity, size。

3. Rapid Prototyping

CNC precision machining + 3D printing synchronous start-up, 72 hours to deliver functional samples。

4. Provide a report

To provide you with a customized product inspection report and production cost forecast.

5. Mass Production & QC

The whole process of digital production, every 500 pieces of full inspection once, support SGS third-party inspection, 7-15 days to complete order delivery.