Supporting Products

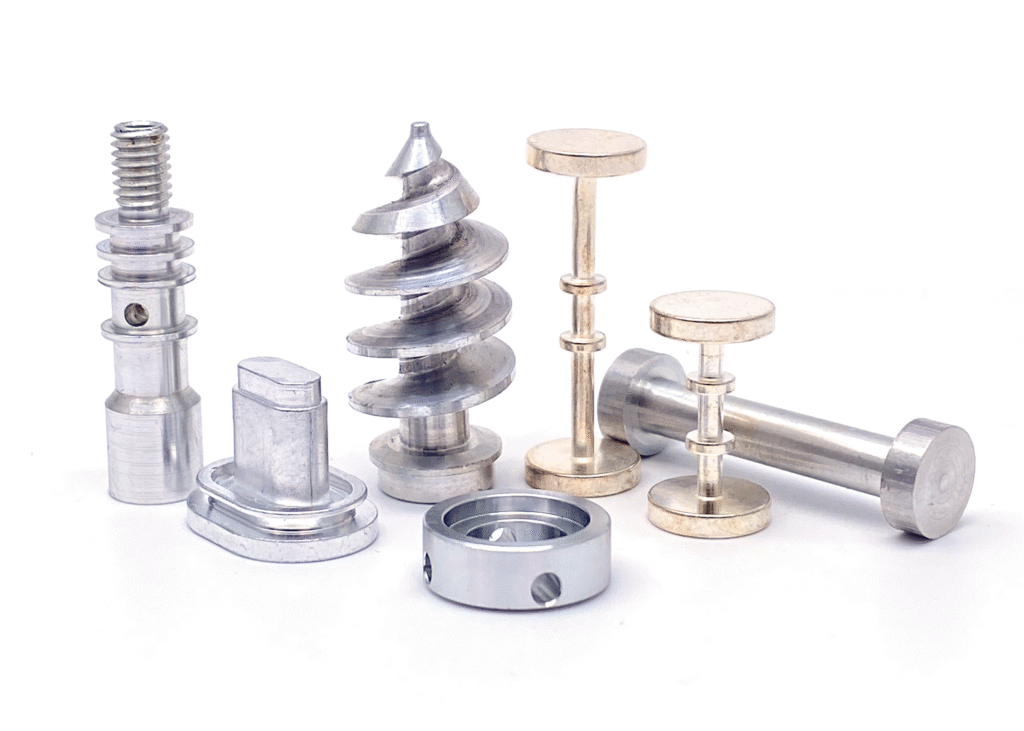

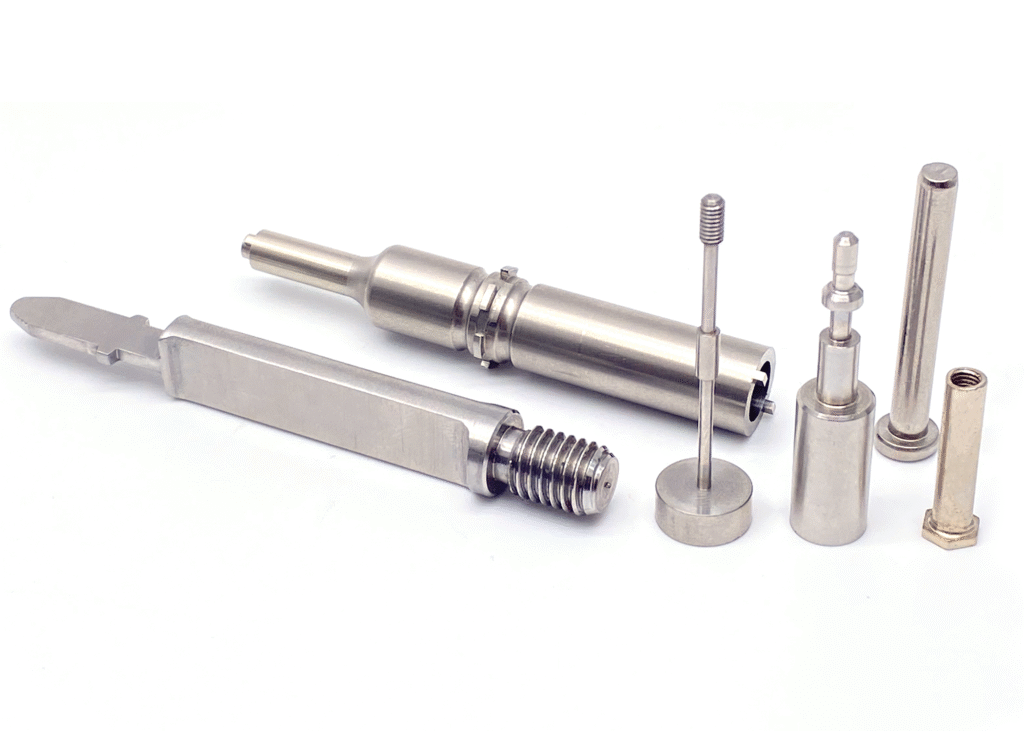

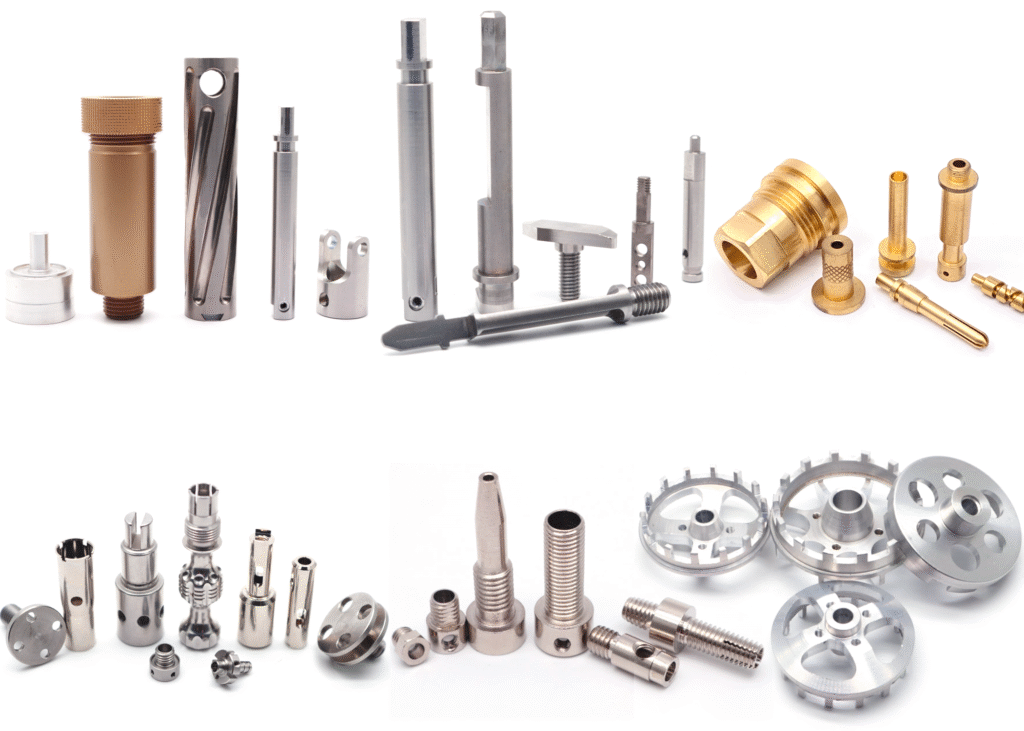

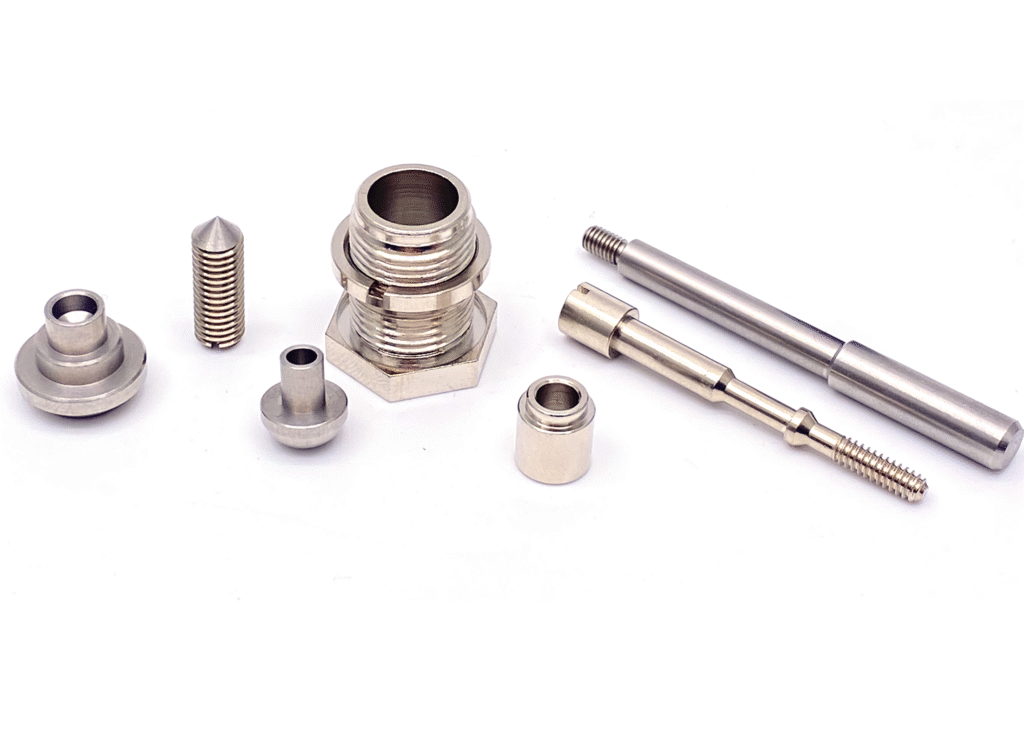

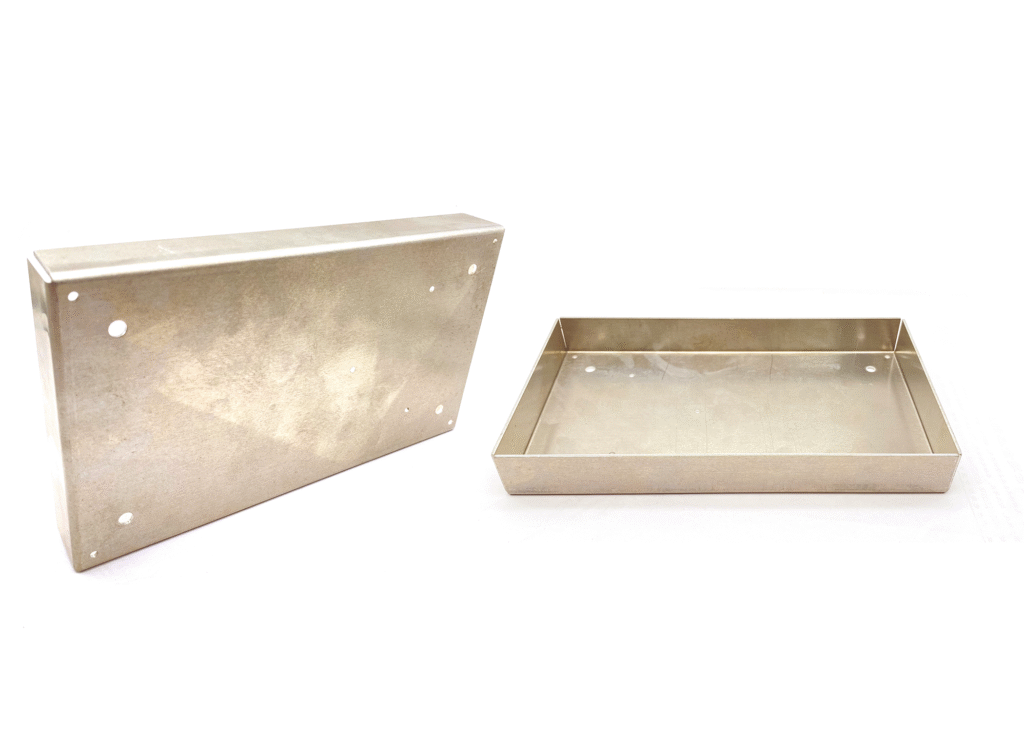

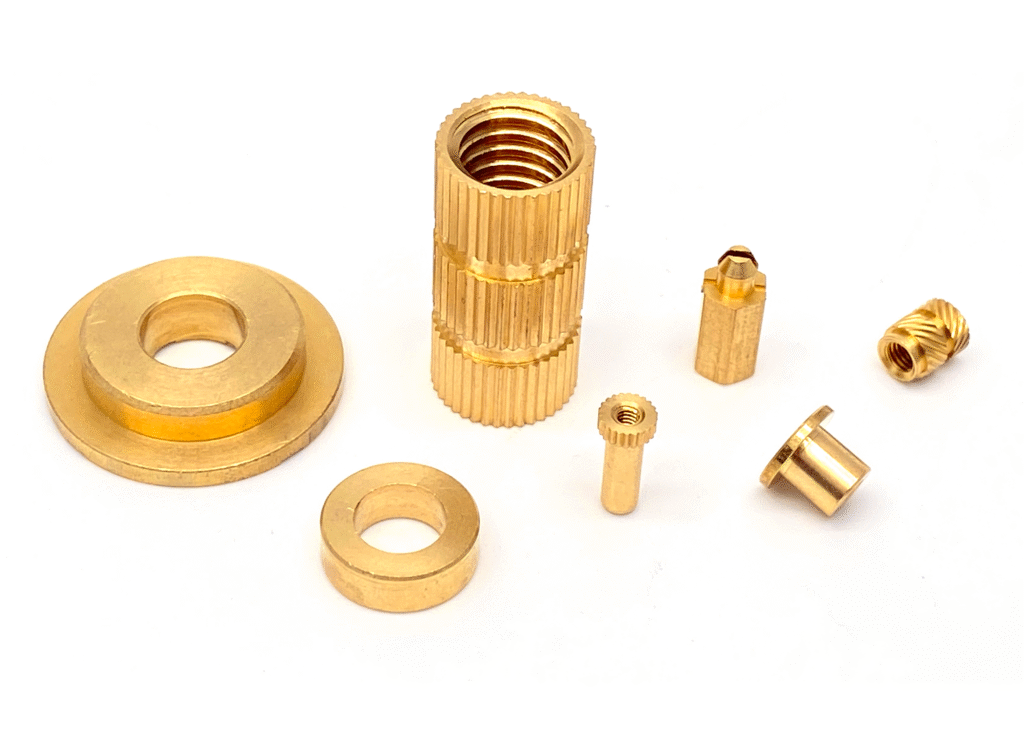

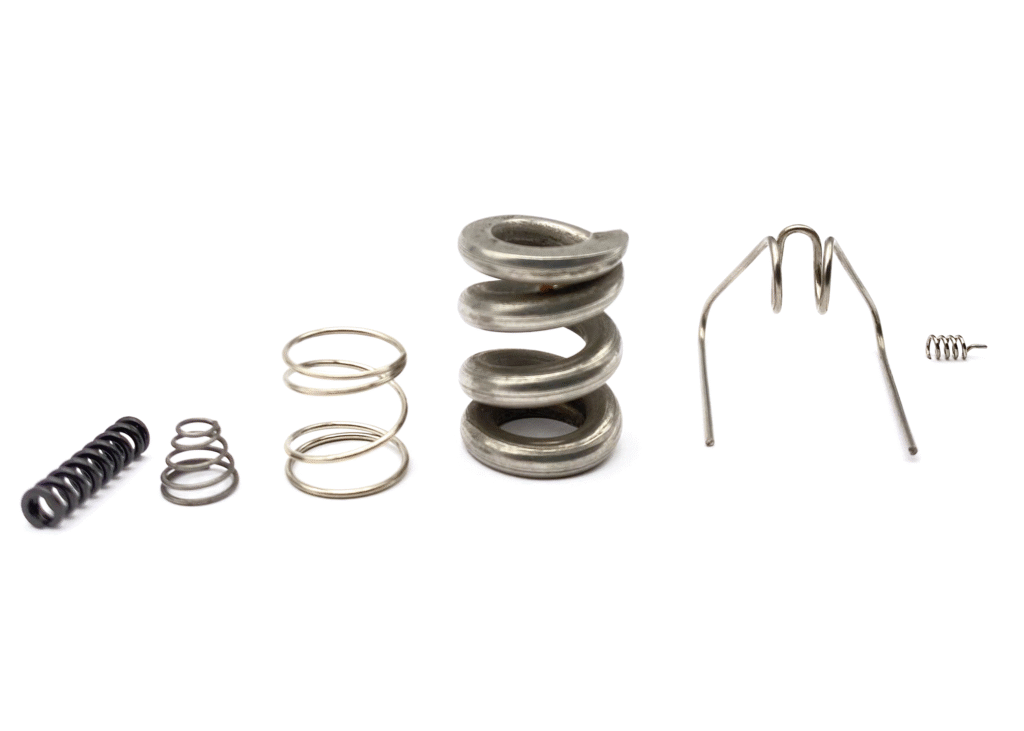

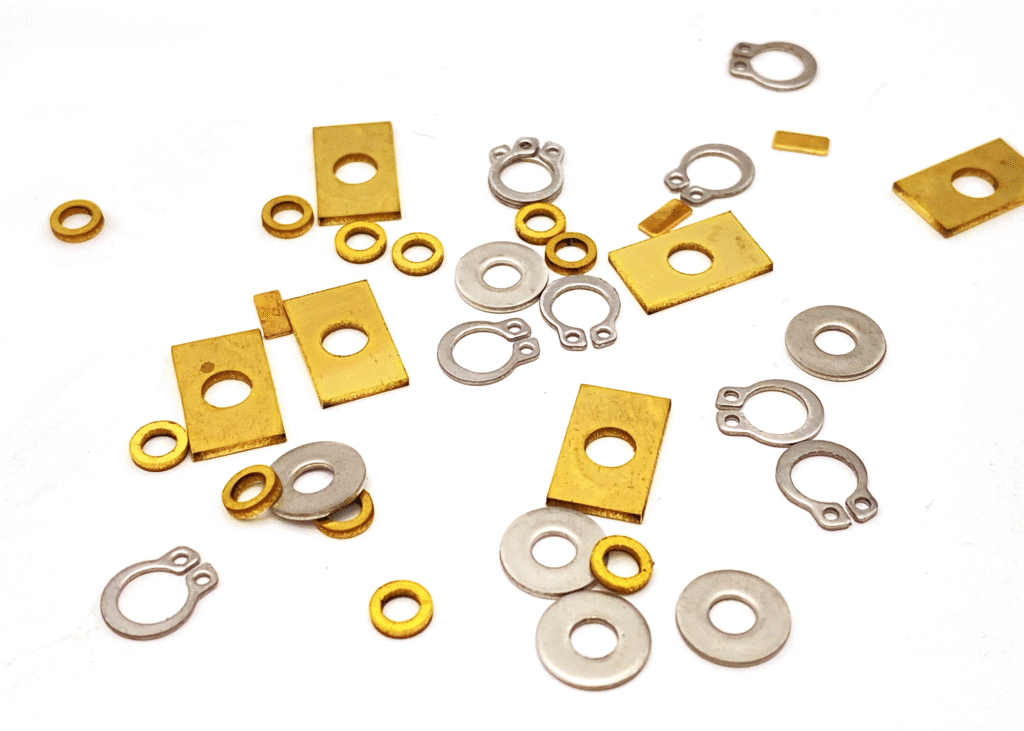

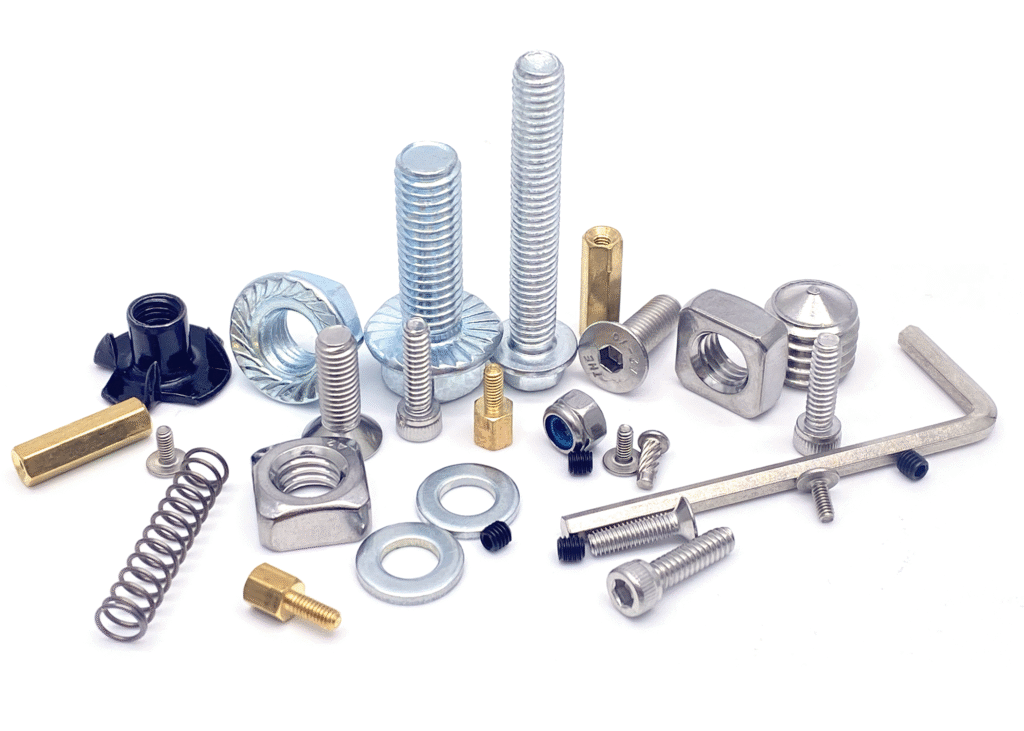

Complete Your Fastening Assembly with Essential Support Products. Find high-quality washers (flat, lock, spring), nuts (hex, lock, flange), inserts, rivets, pins & spacers. Trust SST for all your fastener accessory needs.

Why Us?

Customer benefits | Implementation Path | Data comparison |

Reduce purchasing cost by 30% | Bulk packaging purchase (pipe + Screw + surface treatment combination discount) | Savings in Logistics/management costs compared to decentralized purchasing |

Lead time reduced by 50% | Stock sharing (200 tons safety stock of common materials) | Urgent order, 72 hours, rush delivery |

Zero risk to quality | Material consistency guarantee (the same batch of bar processing pipe + Screw) | Assembly failure rate reduced from 5 per cent to 0.3 per cent |

Material Matrix

Type | Is for material | Capacity under extreme operating conditions |

High temperature resistant tube | GH4145 | Continuous temperature resistance 750 °C/burst pressure 50 mpa |

Corrosion resistant pipe | Inconel 625 | Resistance to 98% sulfuric acid/seawater flow rate of 5 m/s |

Low expansion pipe; low expansion pipe | 4J29 | Expansion coefficient ≤1.8 × 10-6/°C (20-400 °C) |

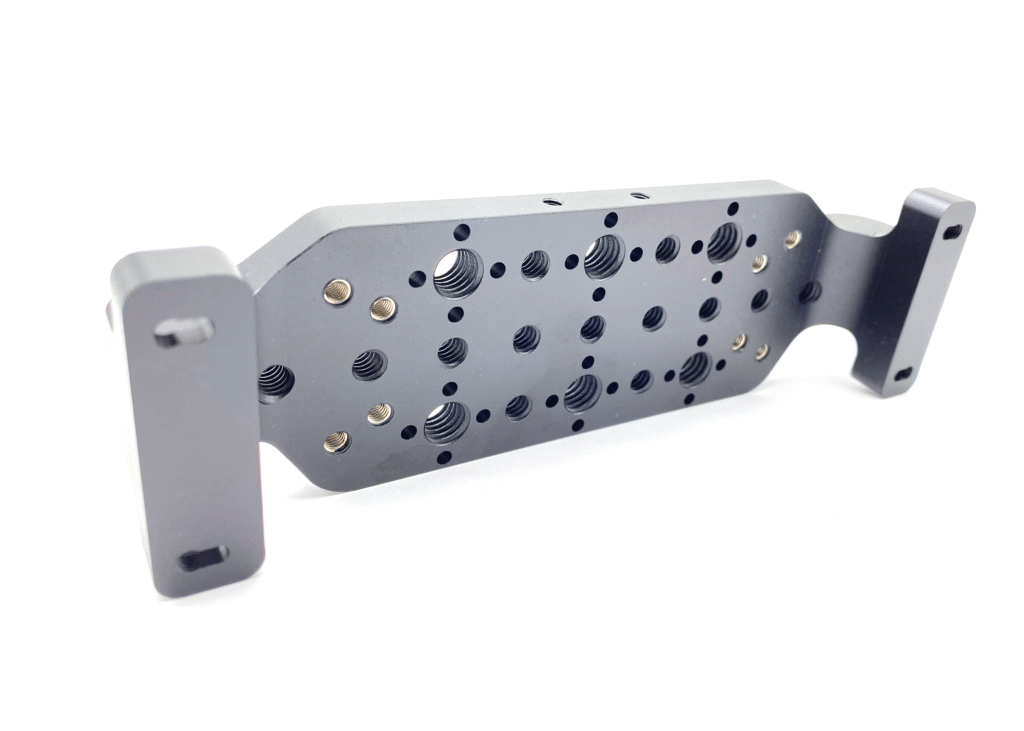

Processing capacity:

– thin-walled tube: 0.1 mm wall thickness (for nuclear magnetic resonance helium cycle lines)

– shaped tube: square tube/bellows/capillary one-piece molding

Guaranteed Performance

Category:

– tape: thickness 0.05-3 mm (1J22 soft magnetic tape for transformer cores)

– microwire: diameter 0.01-2 mm (GH3044 high-temperature wire for spacecraft shielding)

Core Strength:

– supports custom slitting (width/length tolerance ± 0.1 mm)

– provide material traceability report (melting furnace number + heat treatment batch can be found)

Quality Assurance

By ASTM B280 oxygen-free copper grain size detection (average grain size ≤0.015 mm)

Holds API 5CT tubing certification (for high-pressure shale gas wellbores)

Certificate of compliance with EN 102043.1(with spectral analysis report for each lot)

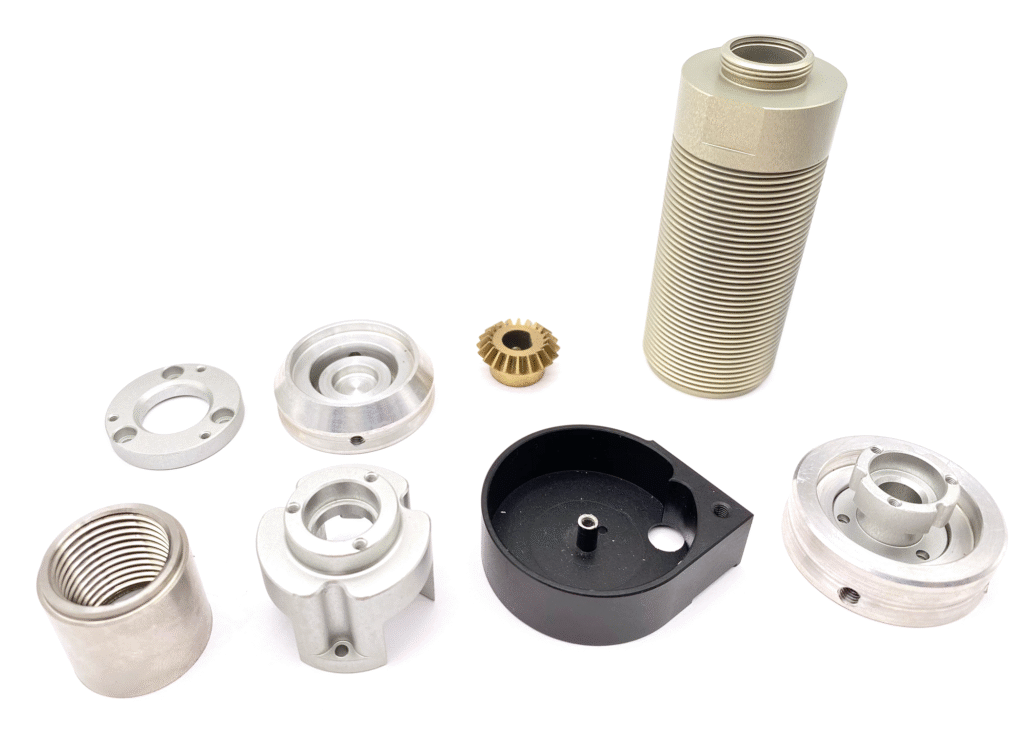

Refer To The Accessory Products

The industry scenario | The matching combination is recommended | Tech highlights |

Semiconductor equipment | 4J29 capillary + 1J79 microwire + oxygen-free copper plate | Vacuum sealing + electromagnetic shielding + ultra-high conductivity |

Aerospace | GH4169 superalloy tube + Inconel 718 bar + HVOF spraying service | Integrated Scheme of 850 °C high temperature resistance and creep resistance |

Energy and chemical industries | Hastelloy C276 pipe + Ernicrmo-4 welding wire + dacromet coating | H2S corrosion resistance + high temperature and high pressure sealing |

Medical Equipment | Titanium alloy capillary (ASTM F67) + medical grade electropolishing + 1J85 soft magnetic tape | Biocompatibility plus zero magnetic interference |

According to the 3 steps to select the matching products for your company.

1. Environment

What kind of harsh environment is your product used in?

2. Texture

We have a variety of materials, high temperature pipe, corrosion-resistant pipe, low expansion pipe; low expansion pipe. . .

3. The industry scenario

Our products are used in semiconductor equipment, aviation, aerospace, energy and chemical industries, medical equipment...