Texture

Achieve the Perfect Grip & Finish with Textured Fasteners. Explore knurled, ribbed, diamond grip & other specialized surface texture fasteners from SST for enhanced handling, anti-slip performance & aesthetic appeal.

Special Nickel Base Alloy

Superalloy | GH4169、GH2132、GH4145、Inconel 718、GH3030、GH3044、GH3039、GH4080A |

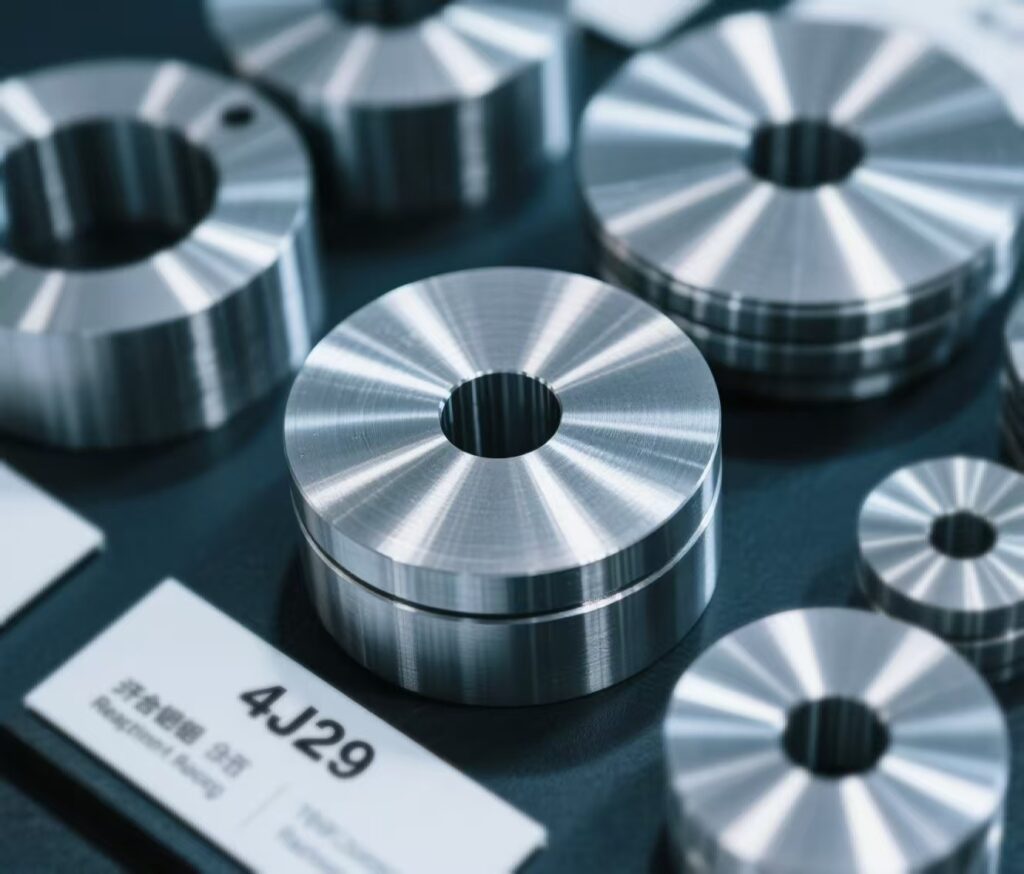

Precision Alloys | 4J36、4J29、4J33、4J32、4J42、4J50、4J34 |

Corrosion resistant alloy | Incoloy 800, Inconel X750, Inconel 600, Inconel 625, Monel, Hastelloy |

Nickel-copper alloy | Monel 400, Monel K500, etc. |

Soft magnetic alloys | 1J50、1J79、1J85、1J22 |

Thermal spraying wire | NI95AL5, Inconel 625, Ernicrmo-3, CR43NI55TI, 45ct, Ernicrmo-4 |

Capillary tubes | Kovar capillary (4J29,4J50,4J42,4J36) , oxygen-free copper capillary, pure nickel capillary |

Superior Performance

NASA reports that its 650 °C fatigue strength is 2.3 times that of Ti-6Al-4V

Perfect sealing with borosilicate glass, used for porthole sealing structure of Shenzhou spacecraft

Zero Corrosion by ASTM G48 standard 48 h salt spray test

Designated magnetic shielding materials for China spallation neutron source project

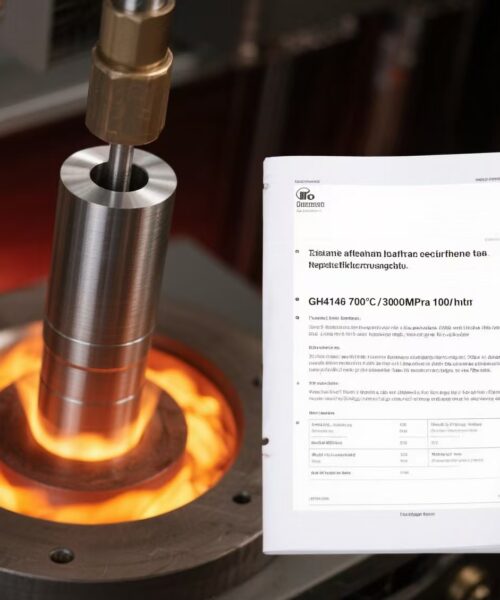

Rigorous Inspection

Direct reading spectrometer (component analysis)

scanning electron microscope (grain size detection)

High Temperature Endurance test report (GH4145 for 1000 H at 700 °C/300 MPA)

Intergranular Corrosion Test Report (Incoloy800 passed ASTM A262 Practice E)

Full-Cycle Manufacturing

Processing with supplied materials

Provide custom cutting for alloy bar/plate/tube

Process instruction

Handbook of cutting parameters for superalloys

Failure Analysis

Material diagnosis report can be provided when customer's parts are damaged

Select your ultimate material according to performance requirements

General category of materials | Stands for plate number | Core performance parameters | Fatal condition scenario | Comparative advantage of competitive products |

Superalloy | GH4169 / Inconel 718 | Temperature resistance 850 °C/tensile strength ≥1450 mpa | Aero-engine combustion chamber fastener | 300 °C higher than that of titanium alloy |

Corrosion resistant alloy | Hastelloy C276/Inconel625 | Resistance to 98% sulfuric acid/seawater pitting | Mixing shaft/offshore platform bolts for chemical reactors | Life is 10 times that of 316 stainless steel |

Precision Alloys | 4J29 / 4J36 | Expansion coefficient ≤1.5 × 10-6/°C (20-400°C) | Vacuum sealing flange for spacecraft | The Hermetic property is 99.8% higher than that of common alloy |

Soft magnetic alloys | 1J79 / 1J22 | Magnetic permeability ≥80,000(1 khz) Coercivity ≤2a/m | Magnetic shielding module for nuclear magnetic resonance instrument | Loss is 70% lower than silicon steel sheet |

Nickel-copper alloy | Monel 400/K500 | Tensile strength ≥750 mpa/seawater stress corrosion resistance | Submarine Valve Assembly/seawater desalination pump | It is 5 times stronger than dual-phase steel in chloride ion corrosion resistance |

3 steps to lock in the best material for you

1.Define the working condition

Select ambient conditions (temperature/corrosive medium/pressure/magnetic requirements)

2. Matching performance

We'll send out an email with a list of recommended materials

3. Get the scenario

You will receive a white paper on material selection under extreme conditions