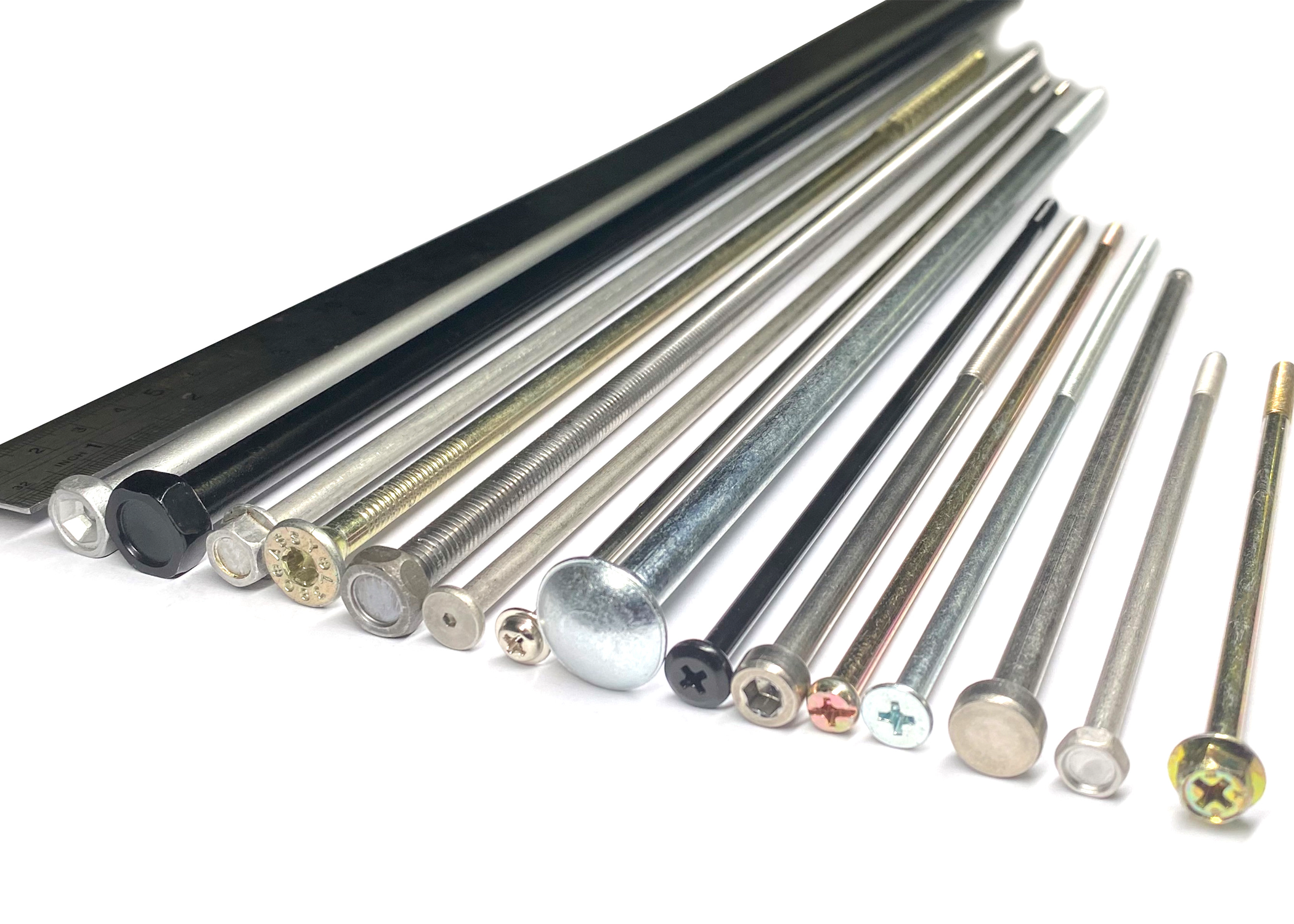

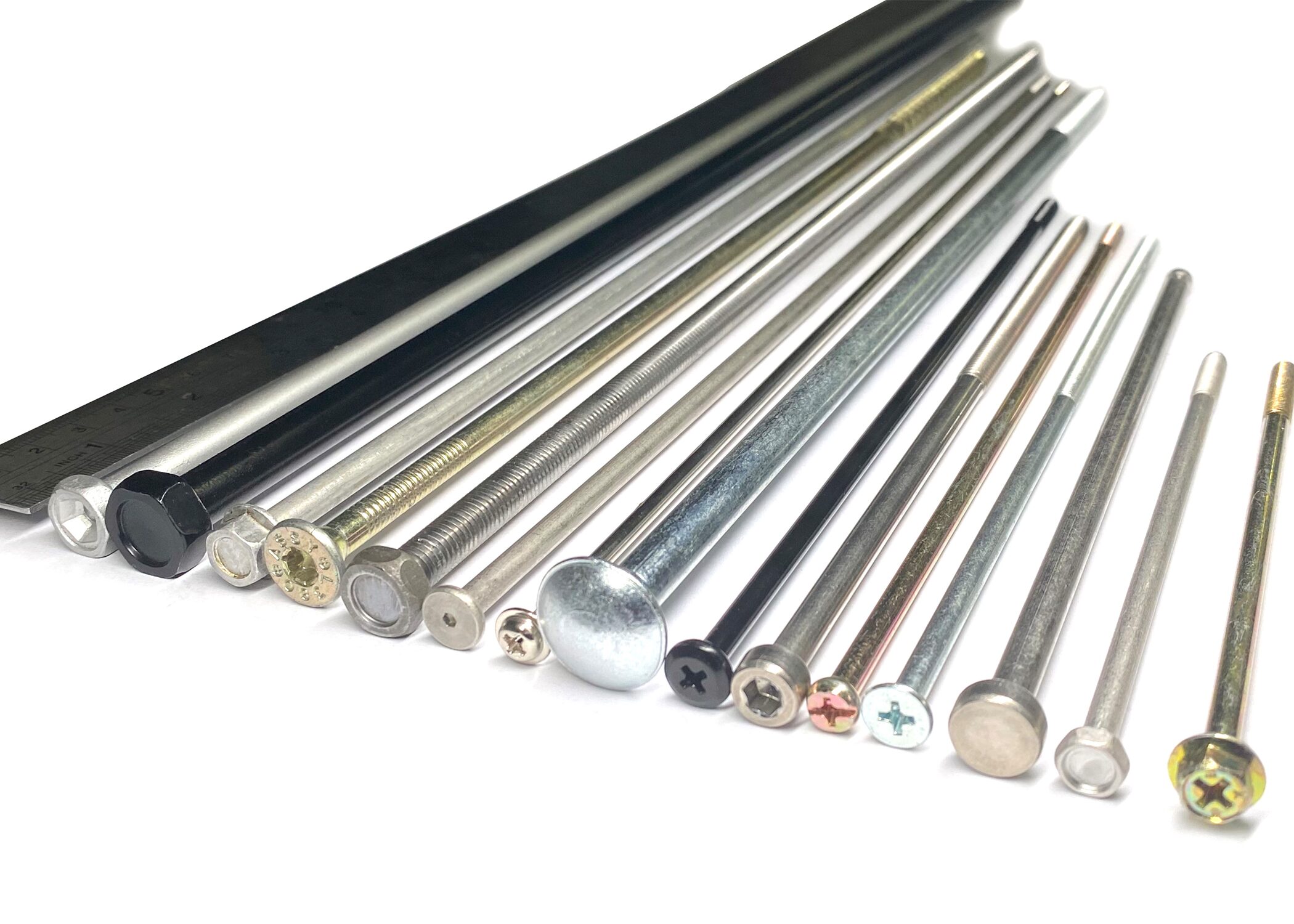

Extesion Screws

Engineered to deliver unmatched tensile strength and threading accuracy, our Extension Screws are globally trusted for critical assemblies. With ISO 9001-certified manufacturing and ±0.01mm dimensional tolerance, we provide scalable solutions for aerospace, automotive, and heavy machinery sectors. Customizable from prototype to bulk production.

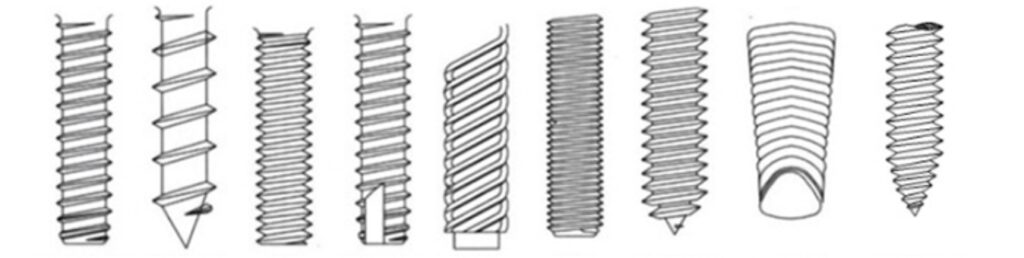

Configure Your Perfect Screw: Dimensions, Threads & Heads

Every detail matters. Select from 12+ thread types (UNC/UNF/Metric), 15+ head styles (Pan/Hex/Button), and lengths from 2mm to 300mm. Our interactive engineering team translates your CAD sketches into certified fasteners within 72 hours. Submit your specs → Receive 3D prototype → Mass production

Material Science Mastery: From Standard Alloys to Exotic Metals

Optimize corrosion resistance, conductivity, and load capacity with precision-material selection:

Core Materials: Stainless Steel (304/316), Brass (C360), Titanium (Grade 5), Aluminum 6061

Specialized: Nickel-Plated, Phosphor Bronze, Hot-Dip Galvanized

Exotic & OEM: Submit proprietary alloys for DFM analysis

All materials comply with ASTM, DIN, and JIS standards with test reports provided.

Have you encountered any of these problems?

The length of the screw is limited

Most factories are stuck at the 200-300 mm length limit and refuse to accept orders for long screws!

Bending deformation of long screws

When the length is more than 500 mm, the bending rate of the screw is more than 60% , which affects the assembly accuracy!

Surface treatment and strength not up to standard

Long screws easy to salt spray not up to standard (< 48 hours) , strength virtual standard, rough surface treatment!

Unstable quality, delay in delivery

Extended screw production cycle of up to 30 days, quality fluctuations!

Our solution

M2-M12 diameters, all-material support (copper/Al/Ti/SS). 12.9 military-grade strength. 500mm bend-free via exclusive heat treatment. Full-process QC with SGS/RoHS + triple test reports. Staged delivery: 3-day urgent | 7-day standard | 15-day full.

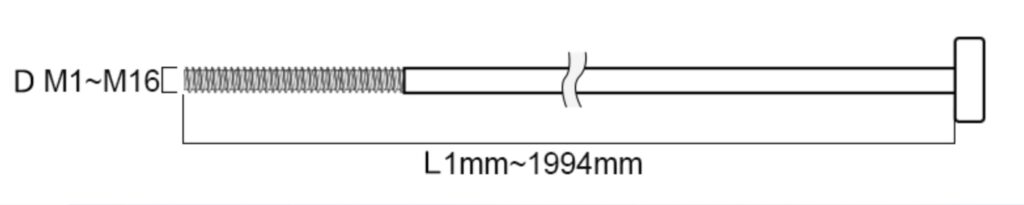

1990 mm ultra-long customization

Diameter cover M2-M12, copper/aluminum/titanium/stainless steel full material support

12.9 military strength

Exclusive fixture heat treatment technology, breaking through 500 mm non-bending limit

Quality inspection of the whole process

SGS/ROHS certification + raw materials/hardness/salt spray test report

Step by step delivery time

Urgent order 3 days into production | conventional 7 days into production | complete 15 days delivery

Quality Control Process for Raw Materials

Implements a rigorous 5-stage raw material validation protocol to ensure manufacturing integrity

01.

Supplier Qualification

Maintain approved vendor lists through regular audits and performance reviews

02.

Certified Sourcing

Procure materials exclusively from accredited suppliers with traceable certifications

03.

Initial Receiving Inspection

QC team verifies material certificates, visual integrity, and dimensional compliance

04.

Laboratory Testing

Conduct destructive/non-destructive testing including:

Chemical composition (Spectrometry/XRF)

Mechanical properties (Hardness/tensile)

Structural integrity (Ultrasonic/X-ray)

Precision measurement (CMM)

05.

Documentation & Release

Digitally archive full test data with material traceability codes

Release approved batches to production; reject and quarantine non-conforming materials

Precision Custom Screws Delivered Fast

Get ISO-certified extension screws engineered to your exact specs. Upload drawings for instant quote & DFM analysis. No MOQ. Global shipping in 5-7 days.

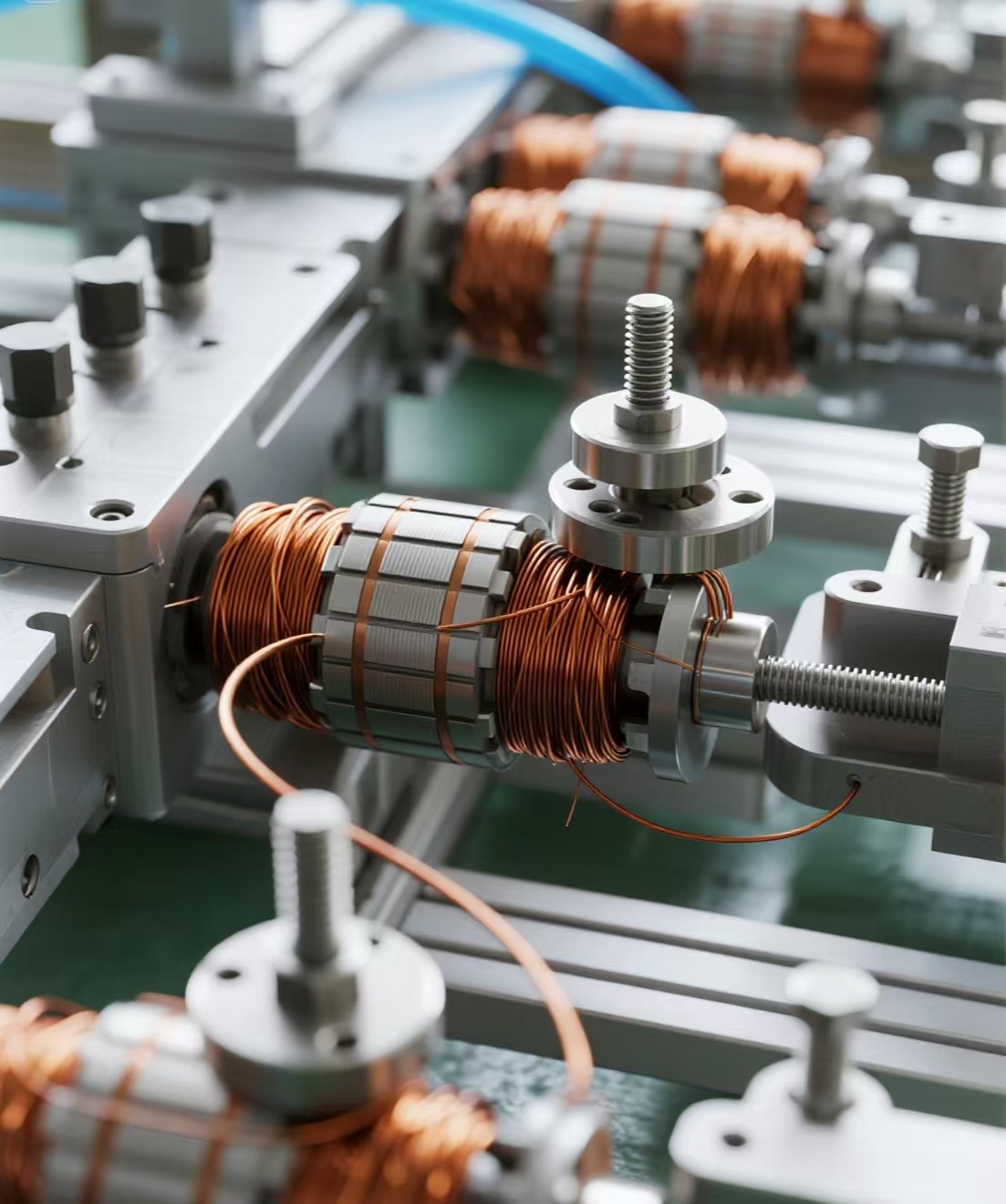

Application scenarios

Motor system

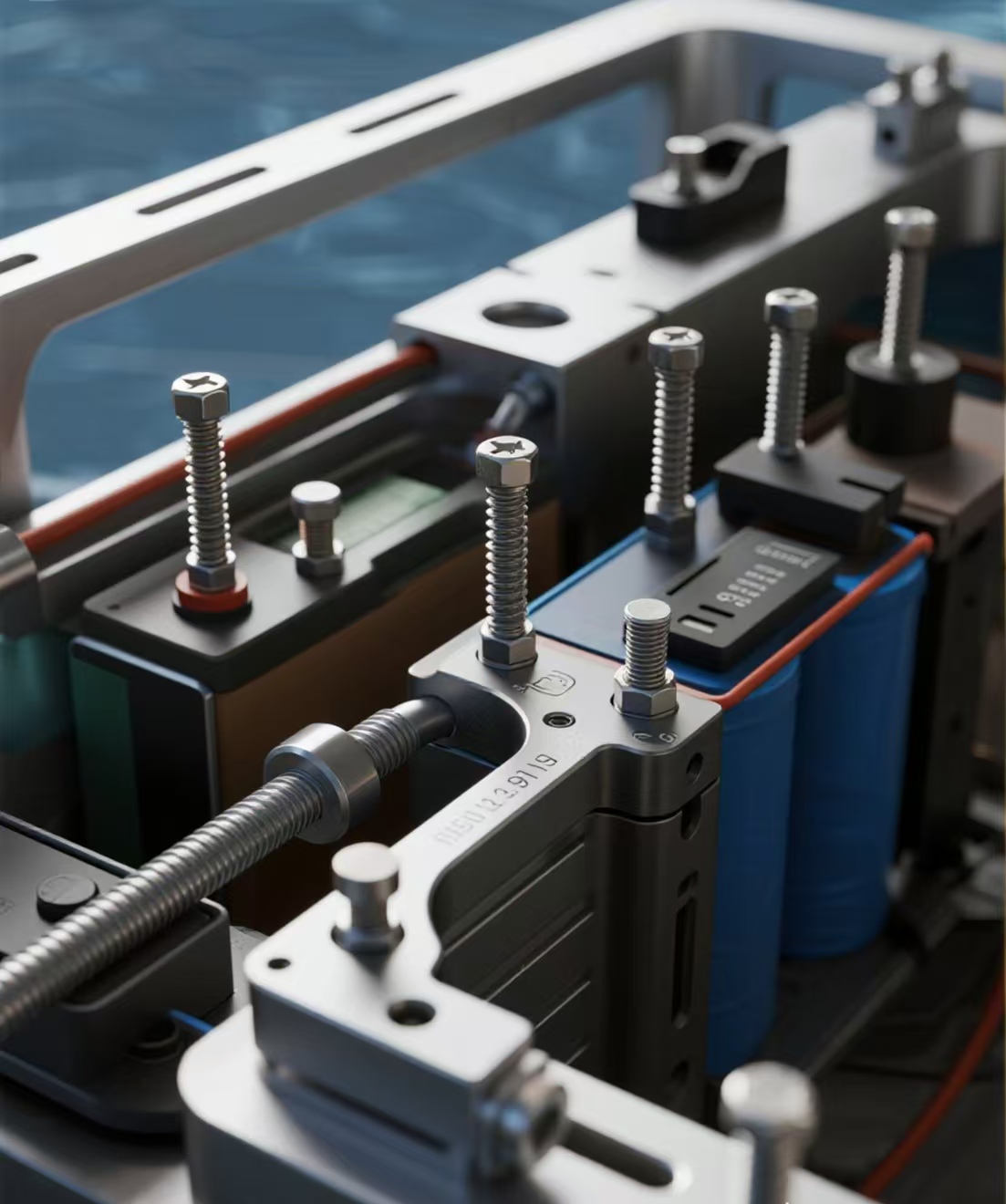

Structural parts of battery

New Energy Storage System

High precision engraving machine

Hydraulic mechanism

Wind power equipment

Switches for industrial electrical appliances

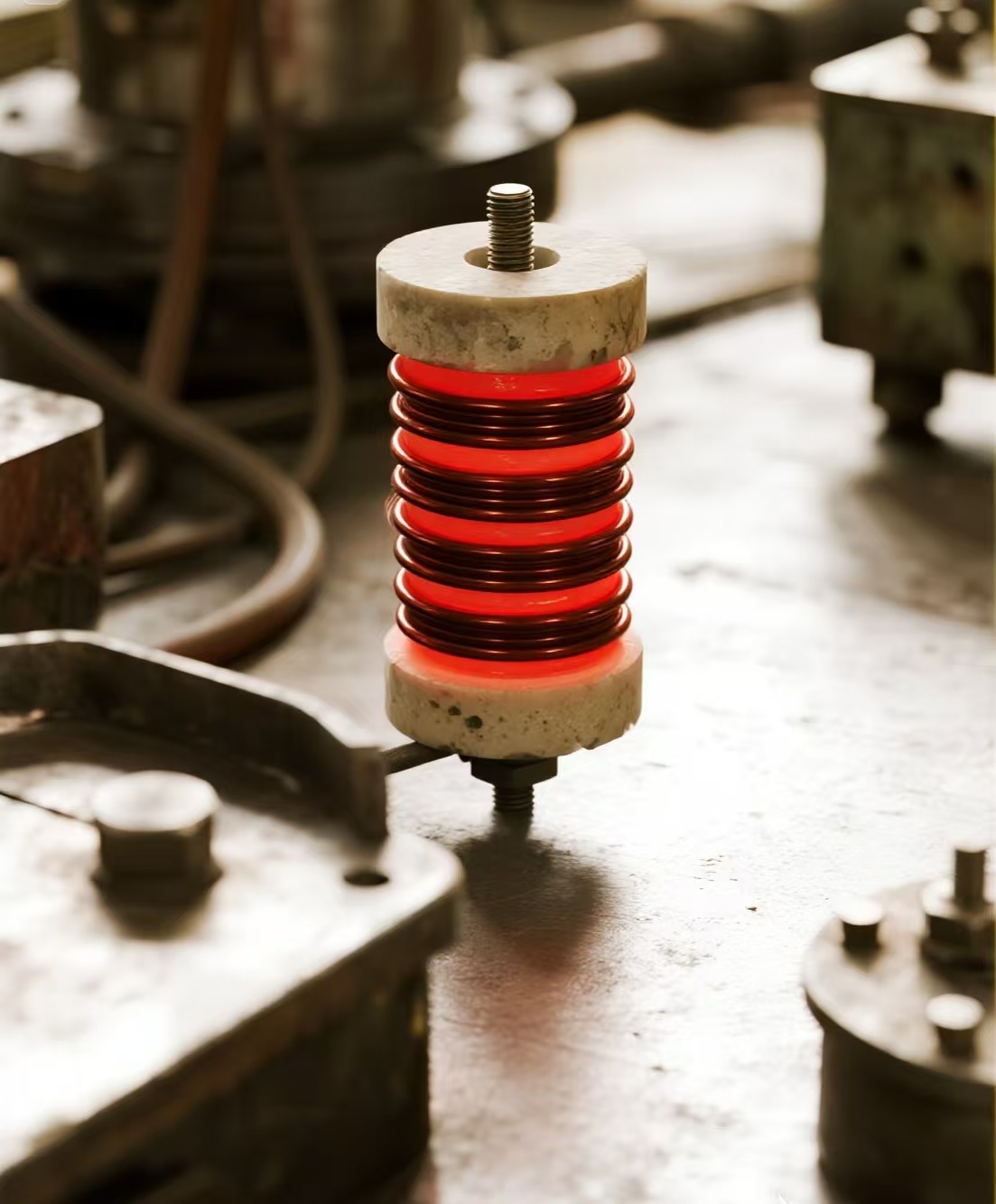

Induction heating system

Our certificate

Our Happy Clients!

we 700 mm extension screw surface treatment requirements are very high, the need for dacromet coating to ensure corrosion resistance. This factory can not only do, but also provide 72 hours of salt spray test report, the quality is very stable. Packaging is also very in place, long-distance transportation is no problem, really very professional!

James Wilson

Procurement Manager

he strength of long screws can really meet the 10.9 level, and can provide Rockwell hardness test report, let us use more assured!

Kelly Joe

Procurement Manager

They are really customizable. We need M10 lengthened screws, 800 mm in length, grade 8.8 hardness, and zinc-nickel alloy finish. They avoid the bending problem entirely. QC testing is very strict, each batch has a detailed report, the quality is very reassuring to us!”

Stella Alba

Procurement Director

Customize the process

01.

Upload Drawing

Submit your technical drawings (PDF/DWG) for free feasibility assessment.

02.

DFM & Quote

Receive design-for-manufacturability analysis and formal pricing.

03.

Confirm & Produce

Approve specifications and initiate bulk production upon payment.

04.

QC & Shipment

Rigorous quality inspection followed by tracked global delivery.

Frequently Asked Questions

Triple military grade quality control system

1 whole process quality inspection: first piece inspection + 30 minutes inspection + full inspection of shipment

299.8% guaranteed yield (industry average < 90%)

3 support SGS/ROHS certification, provide salt spray 300h report + 12.9 hardness report + hydrogen embrittlement test and other 8 test documents

We adopt a stepped extreme speed response

1. Expedited orders: lead time ≤3 days, complete lead time 7-10 days.

2. Regular orders: lead time ≤7 days, complete lead time 10-15 days.

(note: 1990 mm extra-long parts are also applicable when all dies/materials are available)

The world’s only breakthrough technology

1 length: measured support 1-1990 mm (industry upper limit 300 mm)

2 anti-bending: Exclusive fixture heat treatment, 500 mm below 0 bending, long pieces of straightening ± 0.05 mm

3 material: stainless steel/iron/copper/aluminum/titanium full support

Full coverage of authentication matrix

1 quality system: ISO9001 + IATF16949

Environmental certification: SGS + ROHS + REACH

3 strength certification: 12.9 hardness CNAS test report

Behind the premium is a cost revolution

1. Material loss: peer practice > 10% , our breakthrough < 0.2% (full stop defective)

2. Rework rate: peer practice 30% (bending deformation) , our breakthrough 0 rework (exclusive bending technology)

3. Salt spray cost: peer practice 48h namely Rust, our breakthrough 300h maintenance-free (military grade coating)

The Math: 15% higher purchase cost, 300% longer life + 60% lower maintenance cost