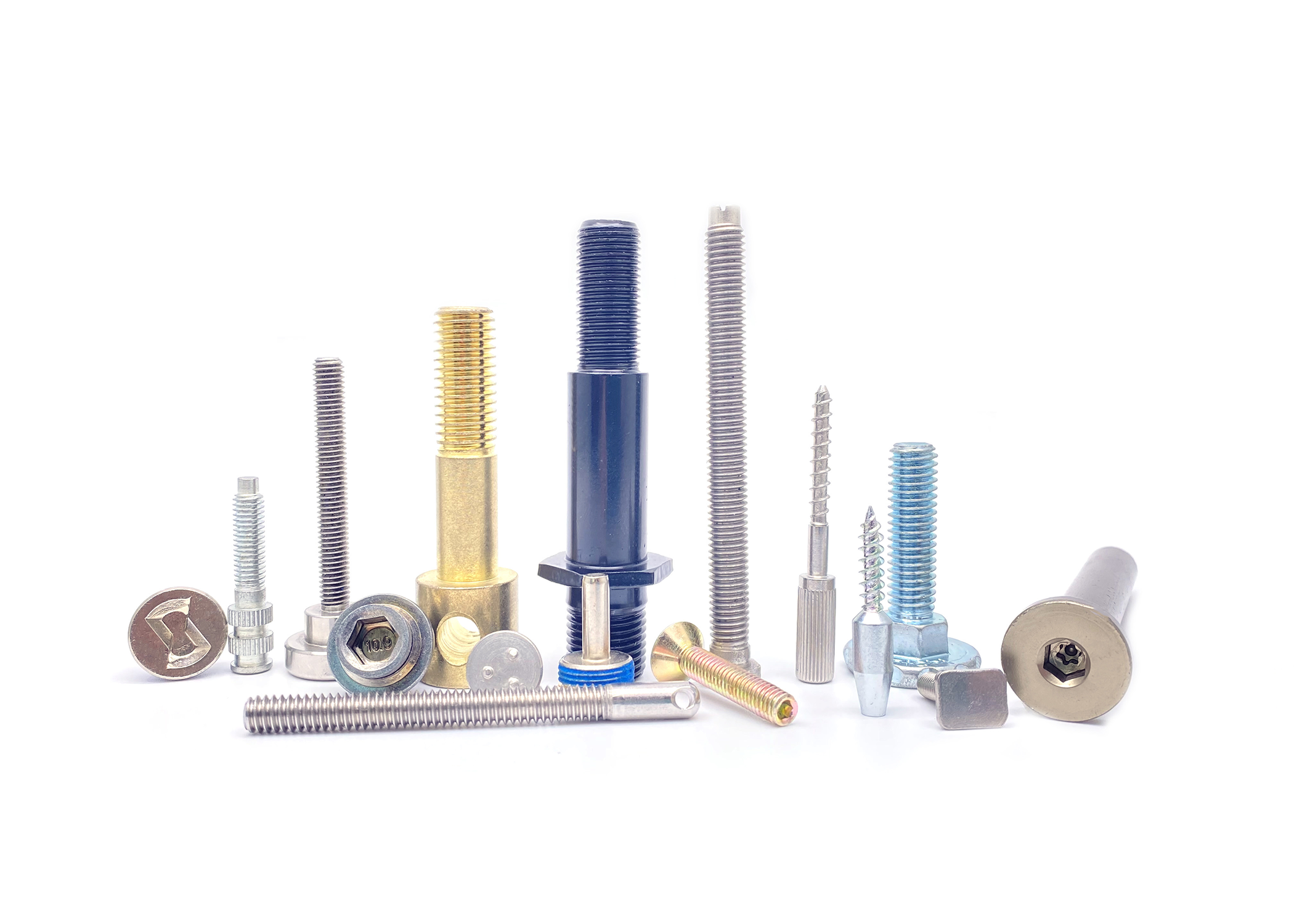

Non-standard Screws

As a vertically integrated manufacturer, we specialize in engineering mission-critical non-standard screws to your exact specifications. From prototype to mass production, our in-house capabilities allow full customization of dimensions, materials, and performance characteristics. Leverage our ISO-certified manufacturing ecosystem to solve unique fastening challenges with screws that simply don’t exist off-the-shelf.

Precision Engineered: Submit Your Specifications

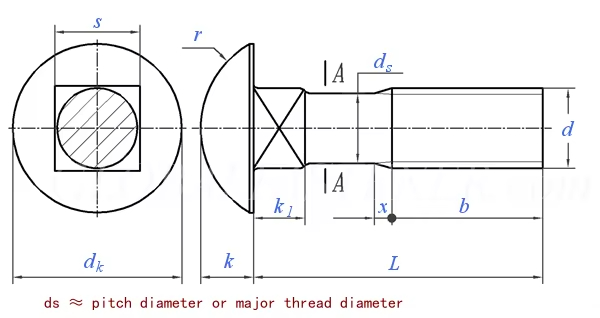

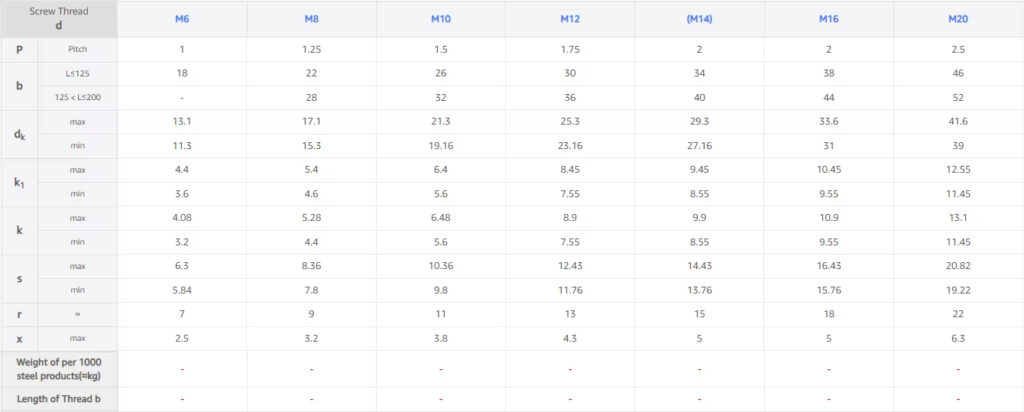

Deploy our technical blueprint (see diagram) as your customization roadmap. Critical dimensions marked [d] are fully adjustable per your engineering requirements. Standard tolerances maintain DIN 2768 Grade Medium unless otherwise specified.

Customization Fields:

Core Diameter: Φ3mm – Φ25mm (±0.02mm)

Thread Pitch: 0.35mm – 3.00mm (UN/ISO/Metric)

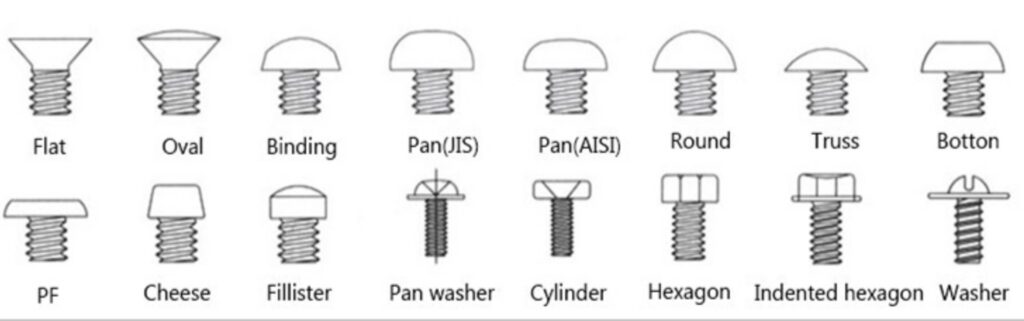

Head Profile: 12+ configurations (Torx, Hex Socket, Custom)

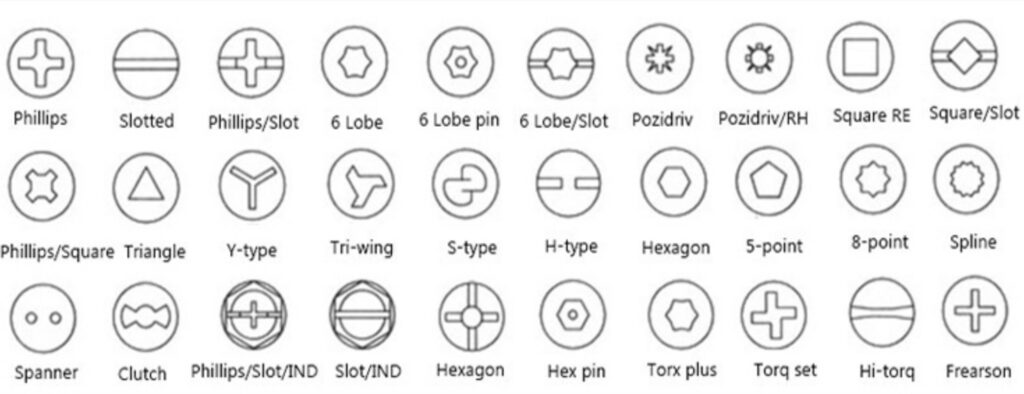

Drive Type: 20+ options (Phillips, Pozidriv, Security)

Upload your CAD files or sketch for instant DFM analysis

Configure Your Fastener: Endless Form-Function Combinations

Our modular design system enables combinatorial customization across three critical domains:

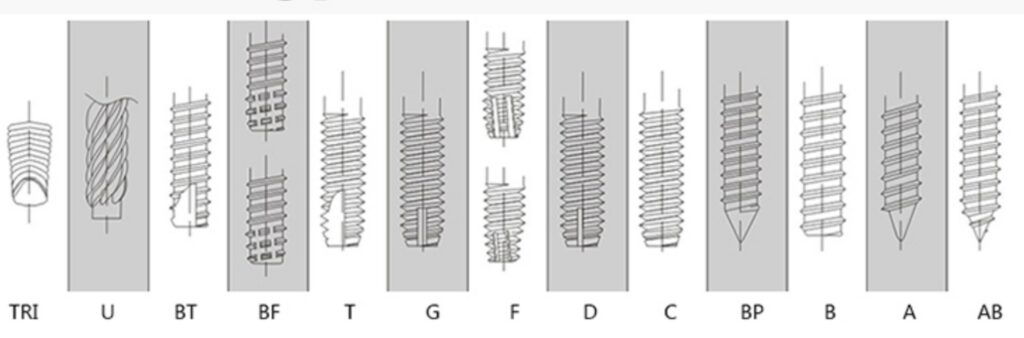

A. Thread Engineering

Profiles: ACME, Buttress, Square, Knuckle (15+ types)

Treatments: Cold-rolled (ISO 898-1 Class 8.8+) / Ground (±0.005mm)

B. Head & Drive Systems

Head Types: Pan, Button, Flat, Oval (with/without washer)

Drive Security: Tamper-proof, One-way, 5-lobe options

C. Material Selection

Standards: Stainless (A2/A4), Alloy Steel, Titanium

Specialized: Nylon, PEEK, Brass with RoHS compliance

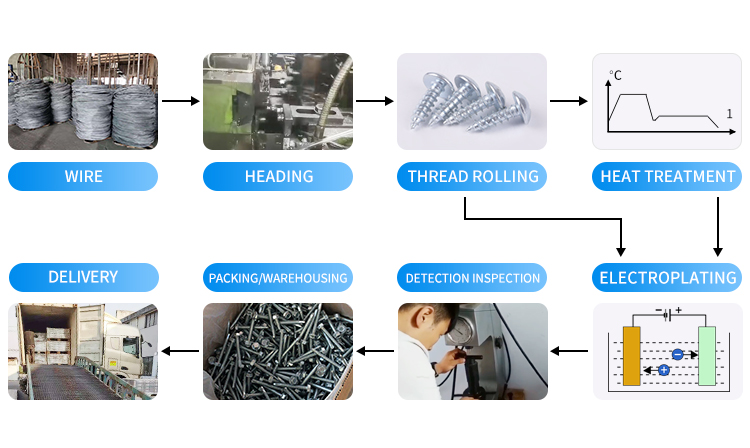

Traceable Manufacturing: From Raw Wire to Certified Delivery

01.

Wire Feeding

Cold heading grade wire (SAE J403)

Diameter tolerance: ±0.01mm

02.

Cold Heading

3-stage impact forming (500-2,000KN presses)

03.

Thread Rolling

Flat-die/planetary systems (60-120 RPM)

ISO 68/ISO 965 thread standards

04.

Heat Treatment

Case hardening: 45-60 HRC

Quenching & tempering per ISO 898

05.

Electroplating

Zinc/Nickel plating (5-25μm)

Passivation: 96+ hrs salt spray test

06.

Metrology & QC

CMM inspection (±0.002mm)

Torque/shear testing (ISO 16047)

07.

Packaging & Logistics

VCI anti-corrosion packaging

FCL/LTL with HS code compliance

Have you encountered any of these problems?

The quality is not up to standard

The strength of screws is nominal or easy to break

No certification of compliance

Special shaped parts have been rejected many times

Only standard parts can be made

suppliers can not undertake non-standard customization requirements

You Can't do extreme structures

Special shaped parts have been rejected many times

Lead time due to insufficient production capacity

Critical delivery delays in supplier capacity

Rejection of special materials

Nobody takes orders for titanium/alloy special materials

Reject mass production after proofing

The sample passed but the batch production was stopped

Breach of trust after delay in payment

Delay and prevarication after payment of an order

Our solution

Mass-produce special-shaped fasteners with 5x over-threaded heads via multi-station automation. Batch-standard prototyping eliminates “sample assassins.” Triple QC + SGS/ROHS certs with H.E./salt spray tests. Urgent non-standard orders fulfilled. Transparent risk management. 20+ materials (C17200/Ti/etc.) with certs.

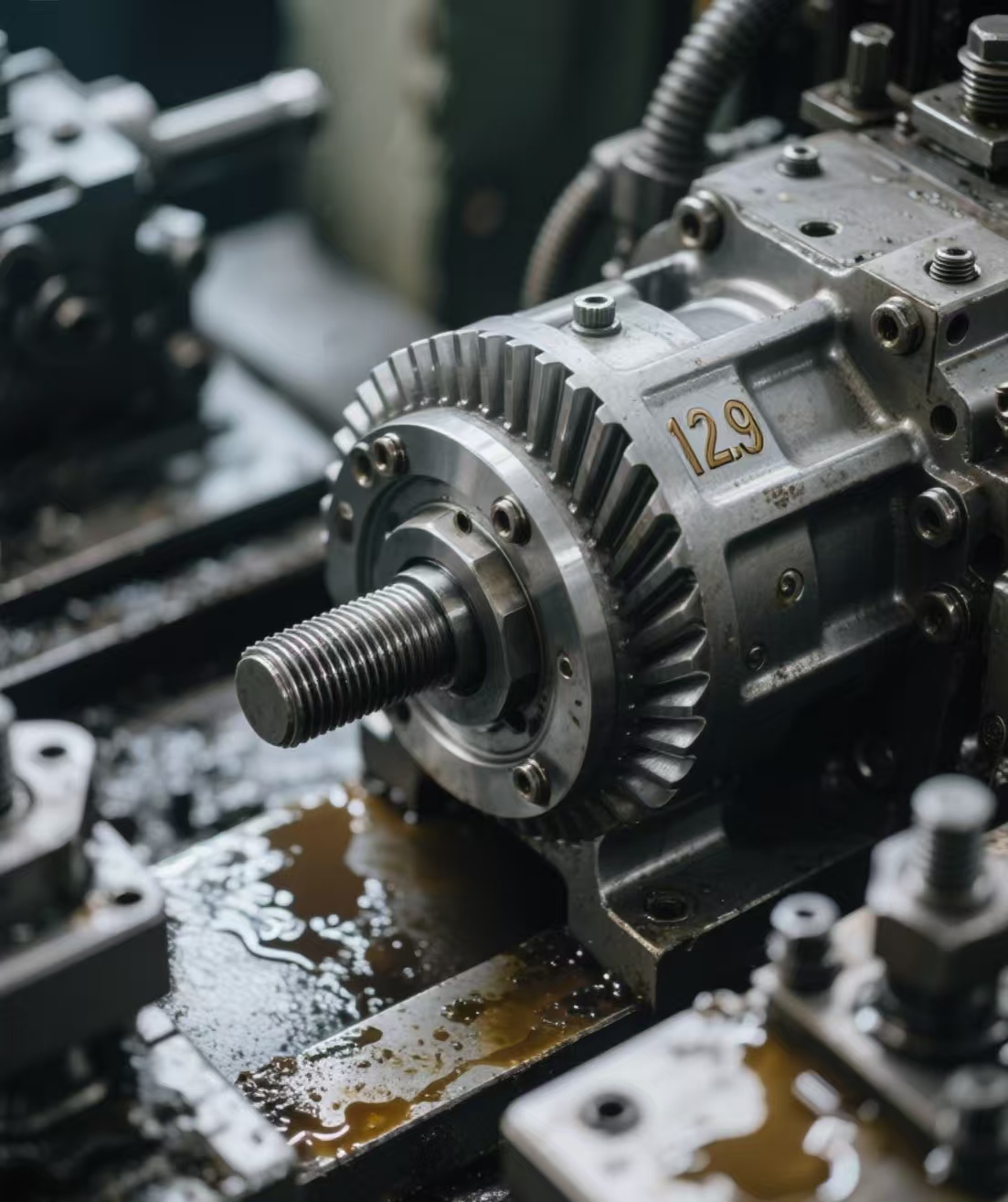

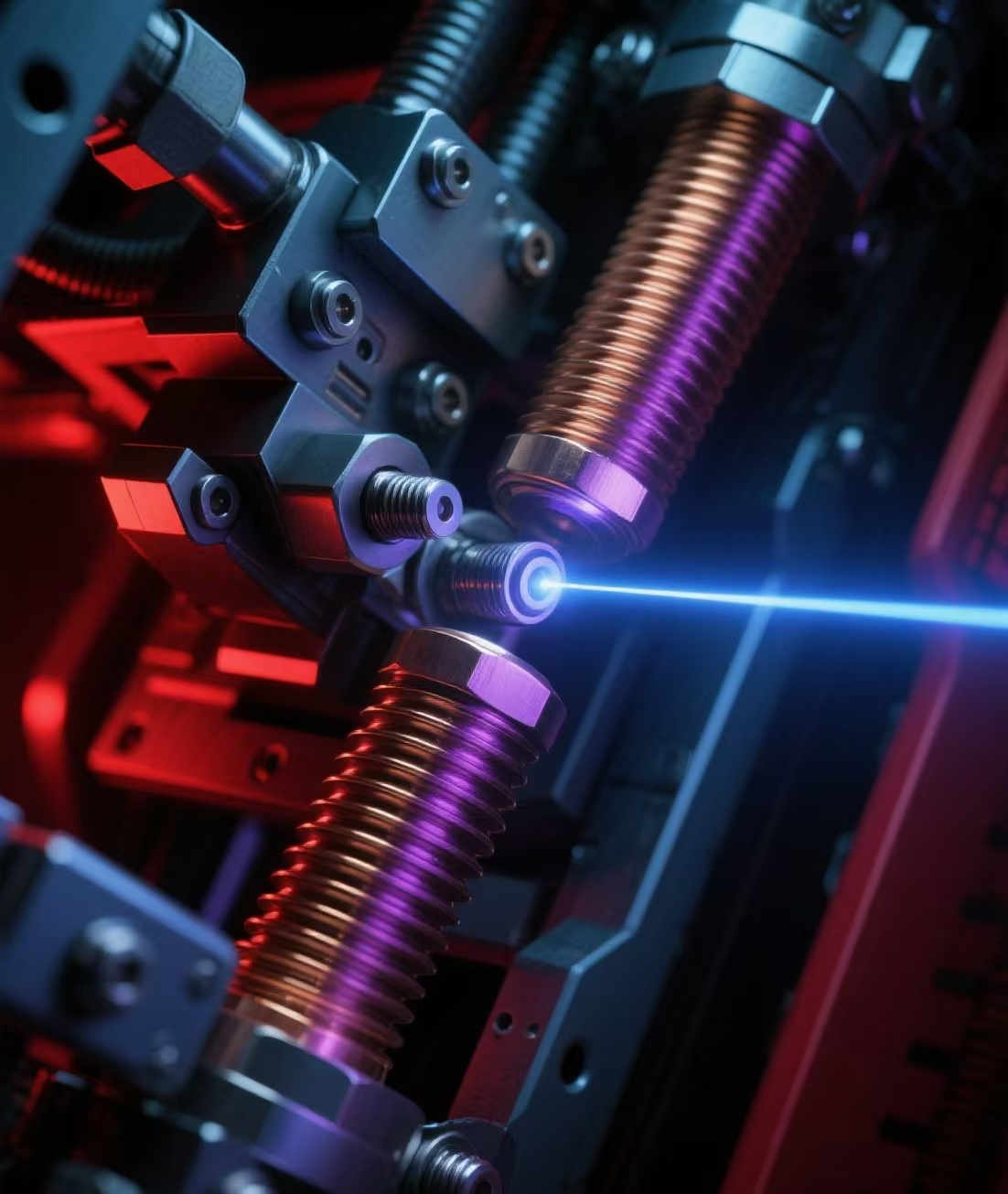

Technology Breakthrough

Multi-station machine for mass production of special-shaped parts with 5 times over-threaded head

Thinking of mass production

Proofing is to produce according to batch standard and eliminate“Sample assassins”

Quality Control System

Three total + SGS/ROHS certification, support hydrogen embrittlement/salt spray 12 test

Production capacity guarantee

Large-scale production of non-standard parts, urgent single response does not jump ticket

Cooperation in good faith

Be upfront about risks and don't take promises you can't make

Special material covering

C17200 beryllium copper/A286/titanium etc. 20 + special materials, with material report

Quality Control Process for Raw Materials

Implements a rigorous 4-stage raw material validation protocol to ensure manufacturing integrity

01.

Supplier Qualification

Maintain approved vendor lists through regular audits and performance reviews

02.

Certified Sourcing

Procure materials exclusively from accredited suppliers with traceable certifications

03.

Initial Receiving Inspection

QC team verifies material certificates, visual integrity, and dimensional compliance

04.

Laboratory Testing

Conduct destructive/non-destructive testing including:

Chemical composition (Spectrometry/XRF)

Mechanical properties (Hardness/tensile)

Structural integrity (Ultrasonic/X-ray)

Precision measurement (CMM)

Precision Custom Screws Delivered Fast

Get ISO-certified extension engineered to your exact specs. Upload drawings for instant quote & DFM analysis. No MOQ. Global shipping in 5-7 days.

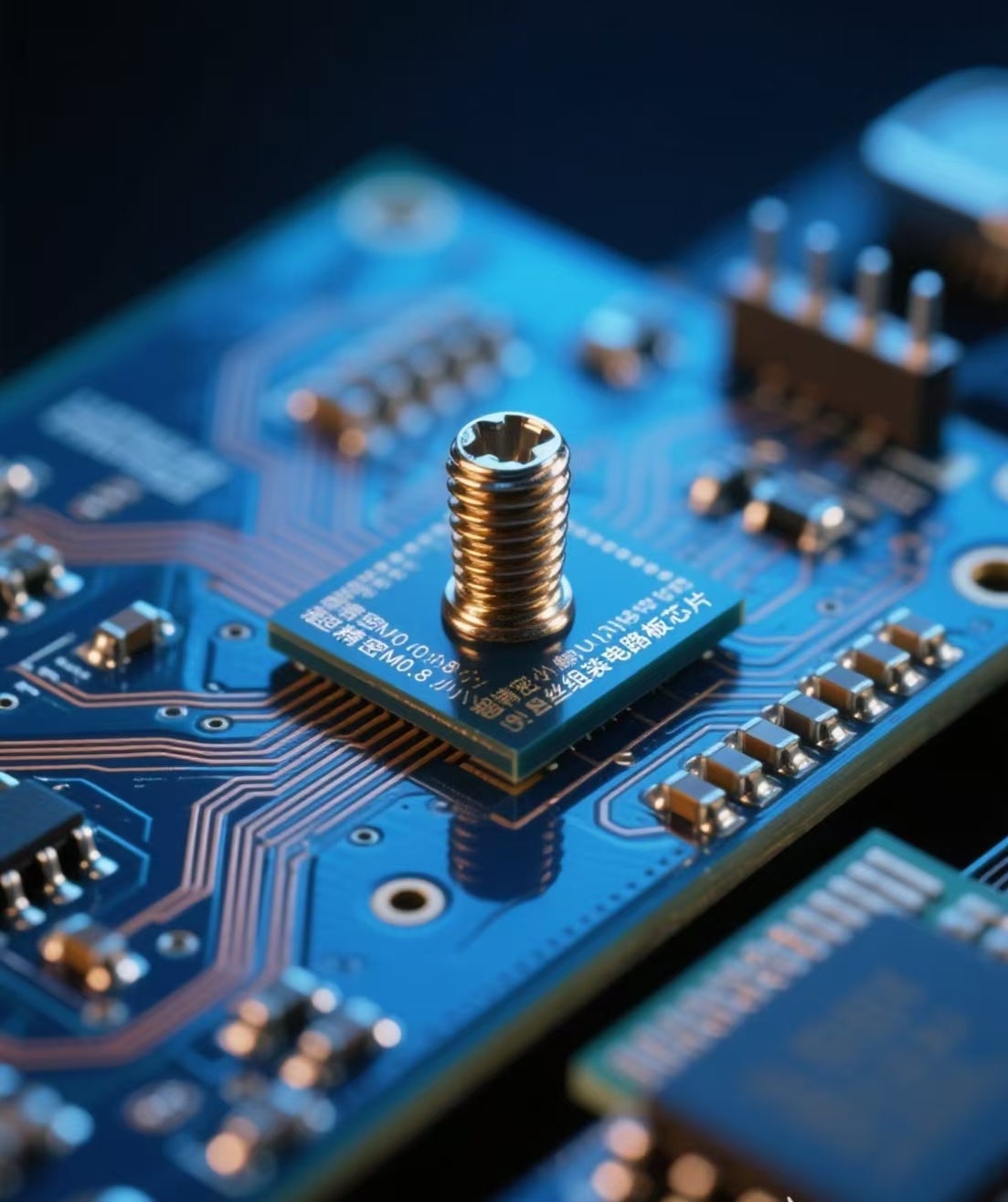

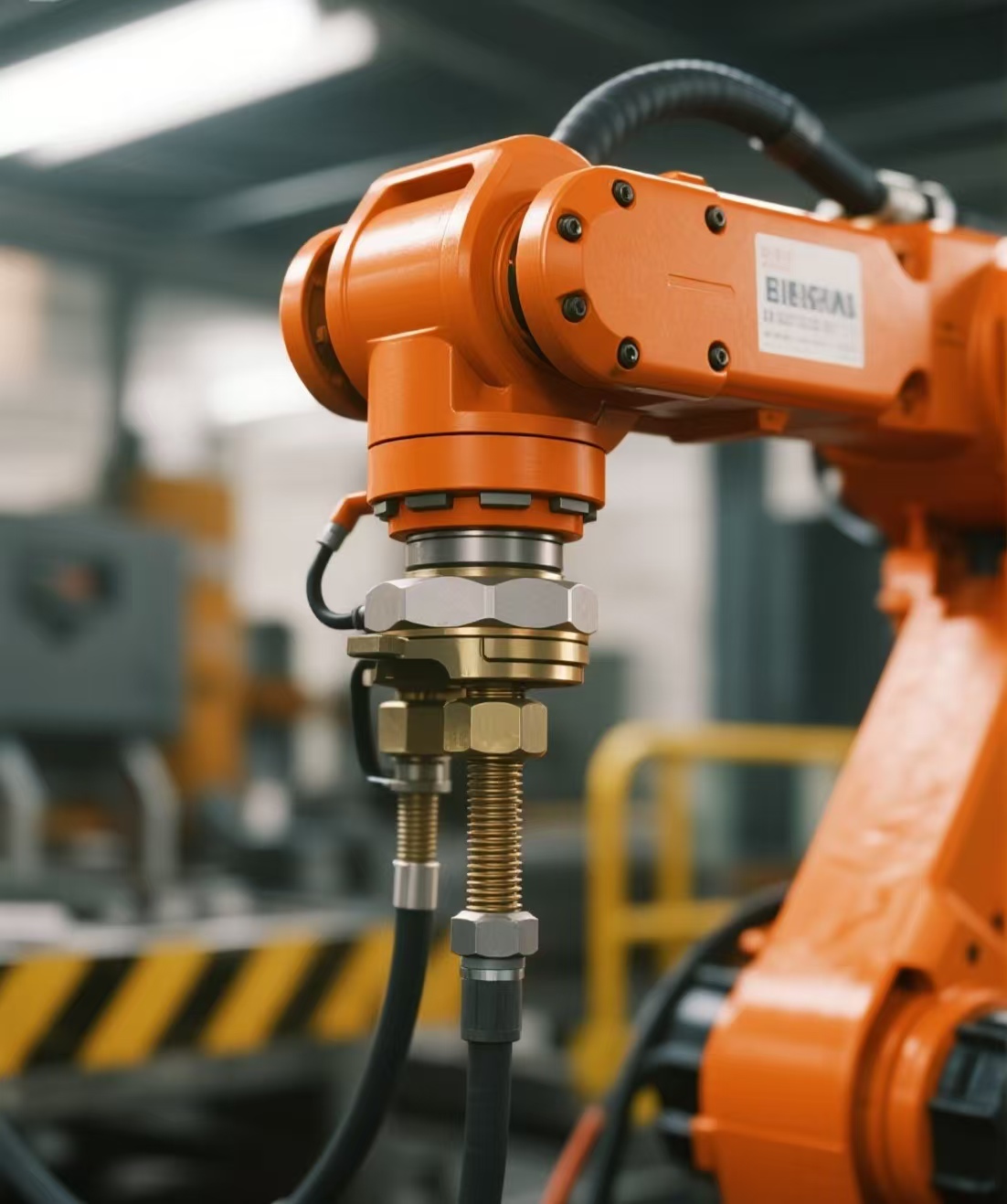

Application scenarios

Smart Home

Industrial Plants

Electronic component

High precision engraving machineElectrical Automation

Medical Equipment

Hydraulic machinery

Electrical Energy

Military Industry and National Defense

Training Equipment

Optics and Electronics

Gas appliances

The rubber and plastics industry

Our certificate

Our Happy Clients!

We asked a lot of suppliers, no supplier can produce cold heading A286 screws, although the shape is the same as the conventional, but the material is too special. We are very lucky to find Worldcom, they can solve this special material of cold heading production, we have received the goods, perfectly meet our requirements, a great cooperation.

Emma Reynolds

Purchasing Man

they are very professional, according to the design of the drawings to see the subsequent assembly of the hidden danger, for us to optimize the design, to avoid our loss.

Thomas Clarke

Procurement Manager

Before we found Worldcom, we had a bad deal. The original supplier hadn’t solved our appearance and size problems. Worldcom solved them and provided us with valuable advice, tell us where we can optimize it so that it’s cost-effective and doesn’t interfere with usage. They’re experts in that area.”

Olivia Khan

Procurement Engineer

Customize the process

01.

Upload Drawing

Submit your technical drawings (PDF/DWG) for free feasibility assessment.

02.

DFM & Quote

Receive design-for-manufacturability analysis and formal pricing.

03.

Confirm & Produce

Approve specifications and initiate bulk production upon payment.

04.

QC & Shipment

Rigorous quality inspection followed by tracked global delivery.

Technical Clarifications Before Quotation

Prototype runs start at 500pcs. Production MOQs vary by complexity but typically begin at 10,000pcs for cost efficiency. Volume tiers available above 100K units.

Yes. Send physical samples for reverse engineering. Our lab performs 3D scanning (resolution: 0.02mm) and material spectrometry.

All manufacturing is ISO 9001:2015 certified. Additional compliance includes:

REACH / RoHS 3

ASTM F1941 (fastener testing)

IATF 16949 (automotive grade)

We employ SPC (Statistical Process Control) with CpK≥1.33 on critical dimensions. Full inspection reports include dimensional data charts per ISO 3269.

Prototypes: 15 working days

Production runs: 30-45 days from drawing approval

Expedited services available for 25% premium