Titanium screw full-scene customization expert

✅ Medical Compliance: ISO 13485-ready, RoHS/REACH reports

✅ Zero Rust: Anodized/Micro-Arc Oxidation, 96-120H salt spray (MIL-STD)

✅ Extreme Environments: -200°C to 600°C stability

✅ Rapid Customization: CNC machining for complex geometries (±0.03mm)

✦ 37+ Yrs Expertise ✦ Batch Traceability ✦ 48H Prototype”

Product Presentation

Have you encountered any of these problems?

Nobody takes orders for titanium screws

Existing supplier technology is not up to standard

Limited surface treatment

Suppliers can not meet the process

The quality fluctuates frequently

Forced to switch suppliers repeatedly

Our solution

Material Breakthrough → full coverage of titanium

Cold heading TA1/Ta2 + turning TC4 precision parts

Medical quality control →99.8% yield

SGS/ROHS/ISO13458 certification

Special material covering → military grade metal customization

C17200 beryllium copper/A286/titanium etc. 20 + special materials, with material report

Customize the solution according to your needs?

Why Us?

Extreme lightweighting

30% weight loss, + 15% range

(aerospace/high-end bicycle screw steel → titanium, density 4.5 g/cm3)

Implant-grade security

Knee implants 0 rejection, titanium allergy rate < 0.6%

(orthopaedic screws/surgical instruments, ASTM F136 certification)

Shield under extreme conditions

Geothermal well screws are acid and alkali resistant + 450 °C thermal corrosion

(energy drilling/industrial furnace, continuous over-service)

Corrosion Terminator

Nuclear power plant valve body screw 0 corrosion, maintenance-free life increased to 5 years ↑

(offshore platform/chemical equipment, salt spray resistance 1000h +)

Magnetic resistance to high temperature

MRI device 0 magnetic interference | jet engine 800 °C strength

(medical imaging/aero-engine fasteners, better than aluminum soften 300 °C)

What are the areas of application?

Naval equipment

Water purification equipment

Chemical equipment

Medical equipment

Smart home

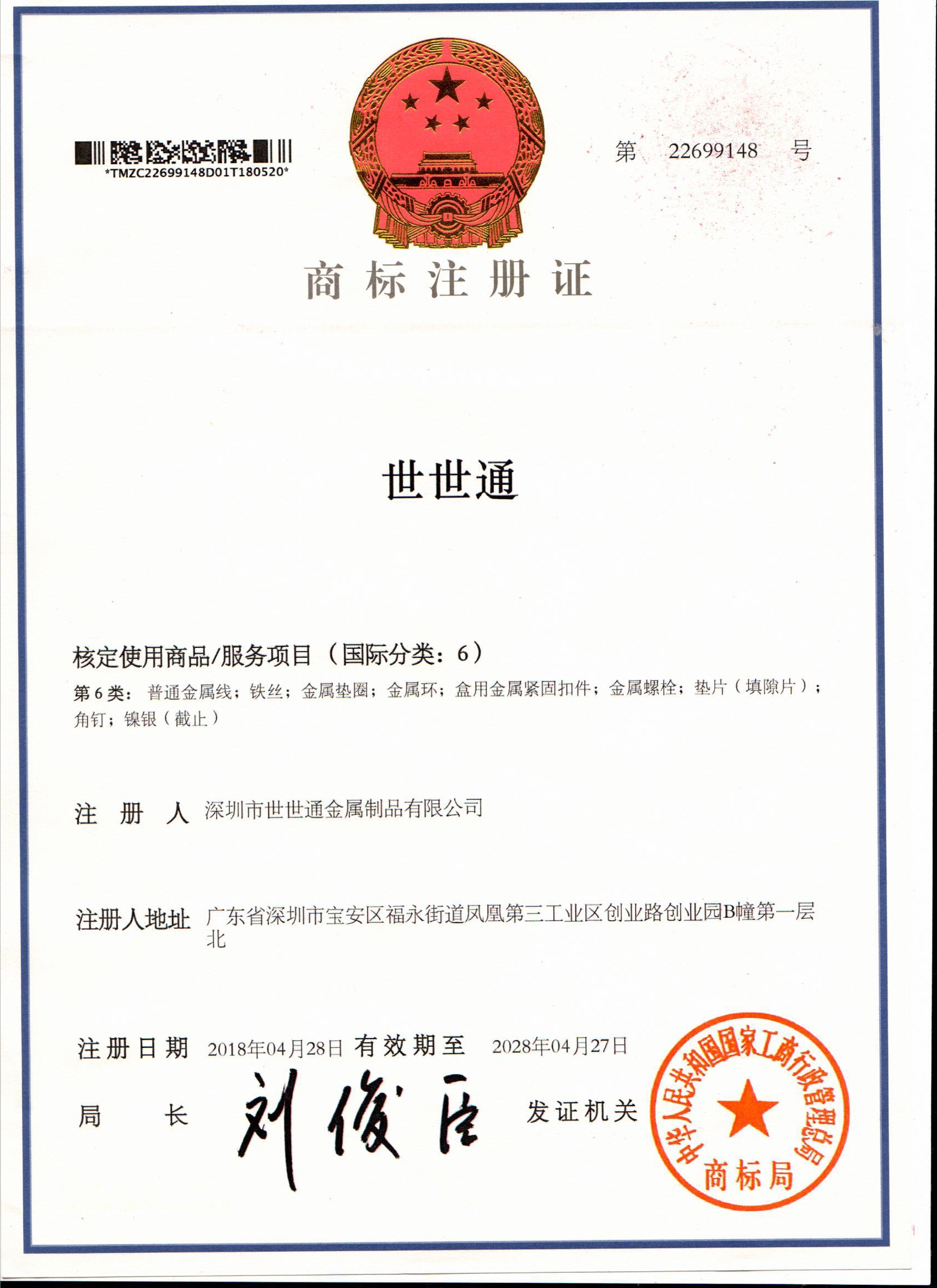

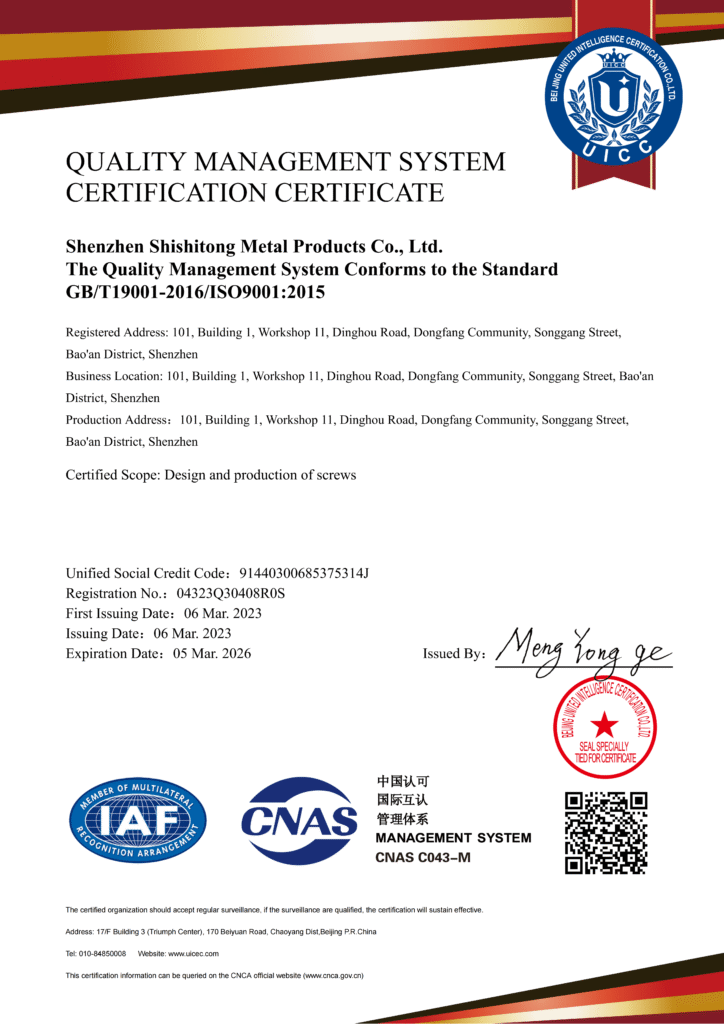

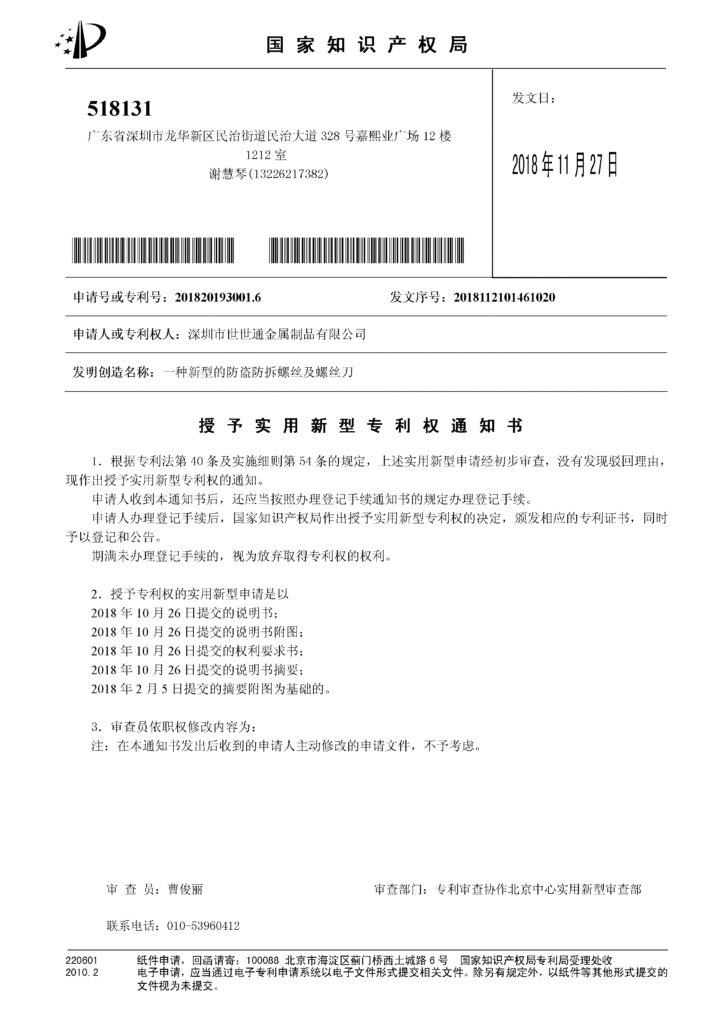

Our certificate

Our Happy Clients!

Customize the process

01

Pre-screening of requirements

Lock size/material/finish/quantity

02

Reinforcement by design

Anti-fracture scheme: groove depth optimization | r angle reinforcement | half tooth anti-loosening

03

Transparent quotation

The process is difficult to quantify and the cost is reduced by 20%

04

Full Price Production Schedule

0 deposit advances, the collection will start

04

Full Price Production Schedule

0 deposit advances, the collection will start

05

Production of military grade

99.8% yield + full inspection of stop gauge

06

Certified Delivery

SGS with goods | delay by day

Frequently Asked Questions

Triple Line of defense

Biocompatible Iron Certificate: ASTM F136 certified, clinical allergy rate < 0.6% (far exceeding ISO 5832-3 standard)

Zero pollution production: 10,000-class dust-free workshop, 100% complete check of implant screw stop gauge

Fatal scenario test: salt spray 1000h | Hydrogen embrittlement test | 800 °C strength retention report (with original data)

Iron Law of military grade delivery

Urgent medical order: 72 hours to deliver orthopaedic implant screws (routine 15 days)

Depth of custom parts: 7 days of shipment (peer average 30 days)

Compensation for overdue date: 2% of the contract amount over 1 day, 30% of the maximum (written into the contract)

Technology: cold heading pure titanium capacity margin: TA1/TA2 threads M1-M12

Technology: Turning Titanium alloy capacity boundary: TC4 precision parts ± 0.01 mm

Technology: micro-arc oxidation capability boundary: Military Gray/deep space black (GB 96H +)

To cover the territory

Medical:ISO 13485|FDA 510(k)|CE MDR

Military industry: NADCAP | AS9100D | GJB

Industry: ISO 9001 | PED 2014/68/E U | Canada CRN

Scenario: orthopaedic implants, hidden cost: $12,000 for second exclusion + titanium option value: 30 years 0 exclusion, Zero Cost

Scenario: desalination, hidden cost: annual corrosion maintenance $8,000 titanium solution value: maintenance-free life > 10 years

Scenario: aero-engine, hidden cost: 1g weight loss = $300 fuel/year titanium solution value: 50% weight loss year-on-year, $150,000 annual savings