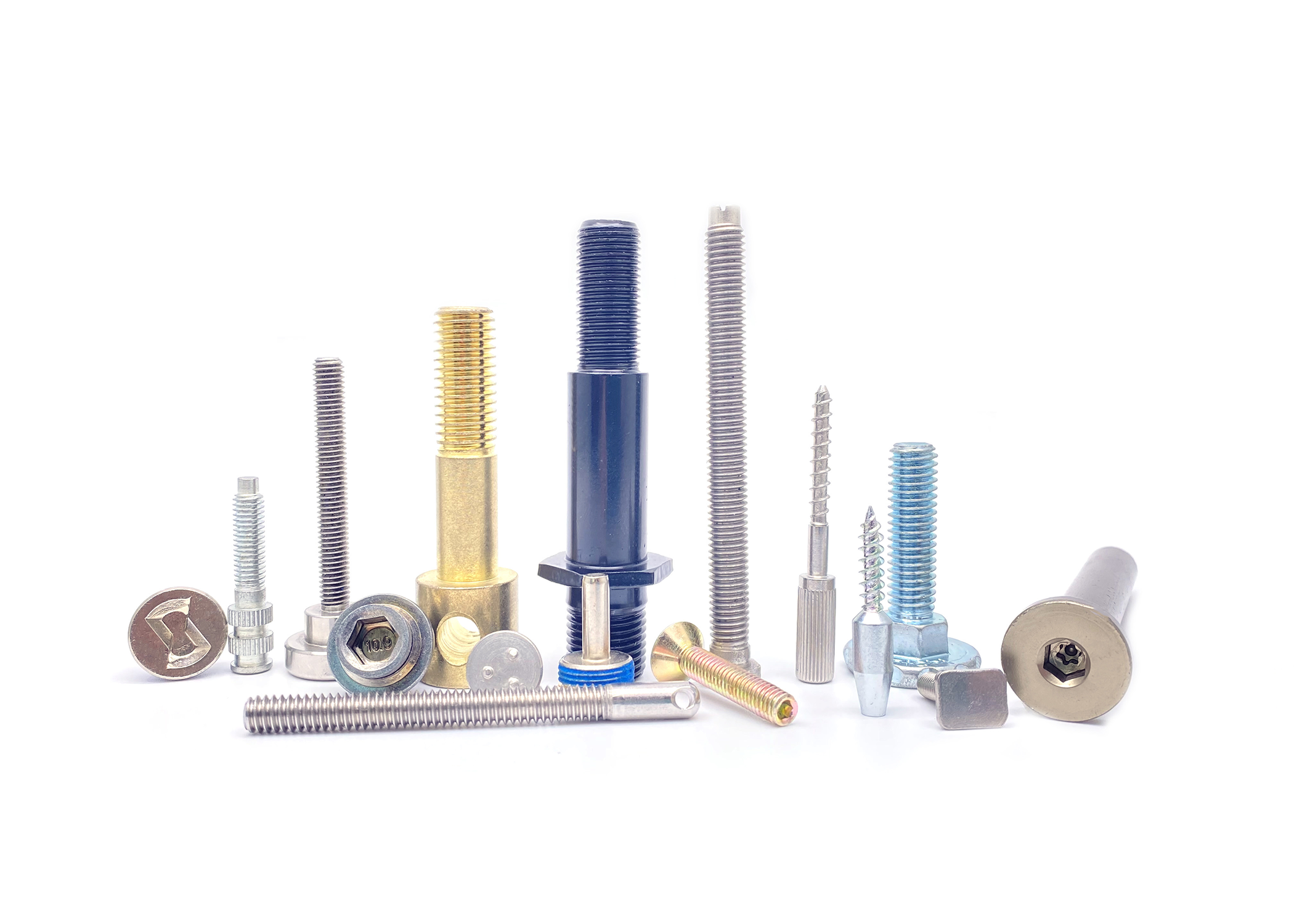

Conventional screws

✅ True 12.9 Strength: Core hardness certified (vs surface-only fakes)

✅ Extreme Corrosion Defense: Zinc-Ni/Geomet®/Dacromet® coatings, 100-300H salt spray

✅ Zero Supply Shock: Auto-fed cold forging, <0.1% hardening defects

✅ One-Stop OEM: Bolts/Nuts/Washers/Springs + Full assembly & packaging

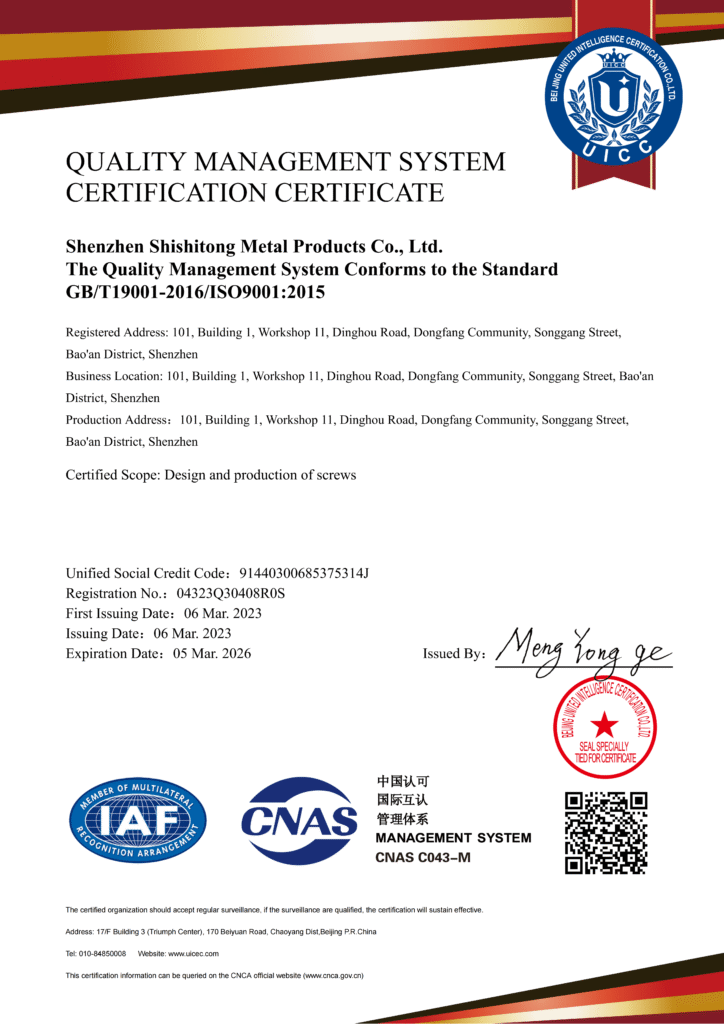

✦ ISO 9001/SGS Certified ✦ 10min Quotes ✦ 37 Yrs Metal Mastery”

Product Presentation

Have you encountered any of these problems?

Out of control premium for long pieces

Length over 300 mm price doubled, cost out of control

False High of strength commitment

Nominal grade 12.9, insufficient hardness of actual core

Salt spray line collapses

48 hours corrosion, equipment life cut in half

High scrap rate of bending parts

Heat treatment deformation, assembly rate dropped by 40%

Addicted to delay of delivery

30-day extension of extra-long parts becomes normal

Our solution

The quality of military industry is uniform

The hardness of the core reaches HRC39-44

The price is controllable

1990 mm length only 35% of the same price, no premium

99.8% good product commitment

Three times quality control, the whole process through the screening stop

20 + items report escort

SGS/salt spray 300 HR/torque measurement full certification

Customize the solution according to your needs?

Why Us?

Cost per unit plummets by 30-50%

Large-scale production of mature specifications (M1-M20) , no tooling cost sharing, bulk order unit price as low as $0.002.

Perfect for:

Cost-sensitive items with annual consumption of more than one million units

50 cities bonded warehouse spot straight hair

√ standing stock: 2000 + standard SKU

√ domestic 24h shipment → Europe and the United States on the 3rd (FedEx/DHL line)

Industry benchmark with 99.2% yield

Automatic production line (16 JDM machines)

100% complete: salt spray test/torque value/hardness gradient

Comply with ASME B18.6.9 N & DIN 7984 Euro Standard

After a listed medical equipment enterprise changed to M 4 standard screw

●60% reduction in parts categories → $128,000 annual management cost savings

● Assembly efficiency increased by 35% (by-product line transformation comparison chart)

Class 10.9 property curve of stainless steel A2-70 V S

Grade 12.9 high-strength bolts passed 100,000 fatigue tests

Salt spray life of 316L stainless steel > 1000 hrs (ASTM B117)

Meet 90% of industrial scene requirements, special working conditions can be connected to custom solutions

Global Service Outlets (Shenzhen/Hamburg/Chicago)

Download Library of 3D drawings of standard parts (STEP/IGES format)

Life-long maintenance commitment: early warning of stoppage Specification + replacement parts recommendation

Our certificate

Our Happy Clients!

Customize the process

01

Precise alignment of requirements

Communicate design/material/process/quantity (1h professional advice optimization scheme)

02

Quotation is transparent and efficient

Assess process difficulty and cost control (1h accurate quotation for complex parts)

03

Guarantee of signing and putting into production

All-section lock · mold synchronization preparation (priority of production line upon payment)

04

The whole process of intelligent construction can be controlled

ISO Quality Control + Progress real-time synchronization On the day of Rush Order

04

The whole process of intelligent construction can be controlled

ISO Quality Control + Progress real-time synchronization On the day of Rush Order

05

Rapid delivery of quality inspection

Global direct mail to the door (support 7th emergency shipment)

Frequently Asked Questions

Full coverage of authentication matrix

1 quality system: ISO9001 + IATF16949

Environmental certification: SGS + ROHS + REACH

3 strength certification: 12.9 hardness CNAS test report

M1-M6 regular parts, 72-hour delivery, we use 24-hour express channel opening

Millions of batch orders, 7 business days delivery, we use exclusive capacity locking + daily progress

Do:

– length 1-1990mm | Grade 12.9(≤500mm)

– salt spray for 1000h (anodic oxidation of titanium alloy)

– ± 0.01 mm precision tolerance (to be confirmed by drawing)

Don’t:

– plastic/woodworking screws | strength below grade 4.8

– non-environmentally friendly processes such as hexavalent chromium plating

Bulk Confidential: 100,000 units minimum order reduced by 12%

Why It’s better:

The cost of turning in the own CNC shop is 40% lower than that of outsourcing

30% post-processing cost can be saved by cold heading process of titanium alloy