Turning parts

✅ Ultra-Precision: Down to Ø0.4mm × 0.05mm thin-walls (±0.005mm)

✅ Exotic Material Wizardry: Titanium/Inconel/Hastelloy/Beryllium Copper

✅ Zero Defect Guarantee: 100% CMM Inspection + Material Cert Reports

✅ Rapid Scaling: 1500㎡ CNC Shop, 4/5-Axis Mill-Turn Centers

✦ AS9100-Ready ✦ 48H Sample Delivery ✦ 37 Yrs Metallurgy DNA”

Product Presentation

Have you encountered any of these problems?

Insufficient dimensional stability

Temperature-induced size drift (± 0.02 mm ↑) It is difficult to control thermal expansion and contraction The precision of batch parts fluctuates greatly

Machining of complex structure

Eccentricity of miniature special-shaped parts Misalignment of thread fit High secondary processing costs

Our solution

± 0.003 mm

Repeated positioning accuracy ± 0.003 mm, radical cure size drift

Special-shaped parts 0 deformation tooling

Special fixture system, completely solve the problem of clamping deformation

Pre-optimization for 3D simulation

The processing path has zero interference, and the efficiency is increased by 30%

Full escort of third-order detection

First complete inspection → process sampling → final inspection 100% retest

DBMS parameter database management

Cloud archiving process parameters, yield 99.8% +

Customize the solution according to your needs?

Why Us?

1.Ultra-high precision (± 0.003 mm)

Solving the pain point of assembly failure of precision parts

2. Complex geometry forming

Turning special-shaped structure 0 cost premium

3. Flexible customized production

Mold-free 72-hour prototype delivery

4.Properties of strong and tough materials

Improvement of wear resistance of titanium/alloy turning parts

5.Extreme Environment Programme

Corrosion resistant Inconel parts salt spray 1000h

6.Emergency capacity response

Turning Rush Order 7 days worldwide delivery

7.A revolution in process substitution

0 porosity turning parts yield is 99.8%

Application scenarios

Automobile manufacturing

Eectronic equipment

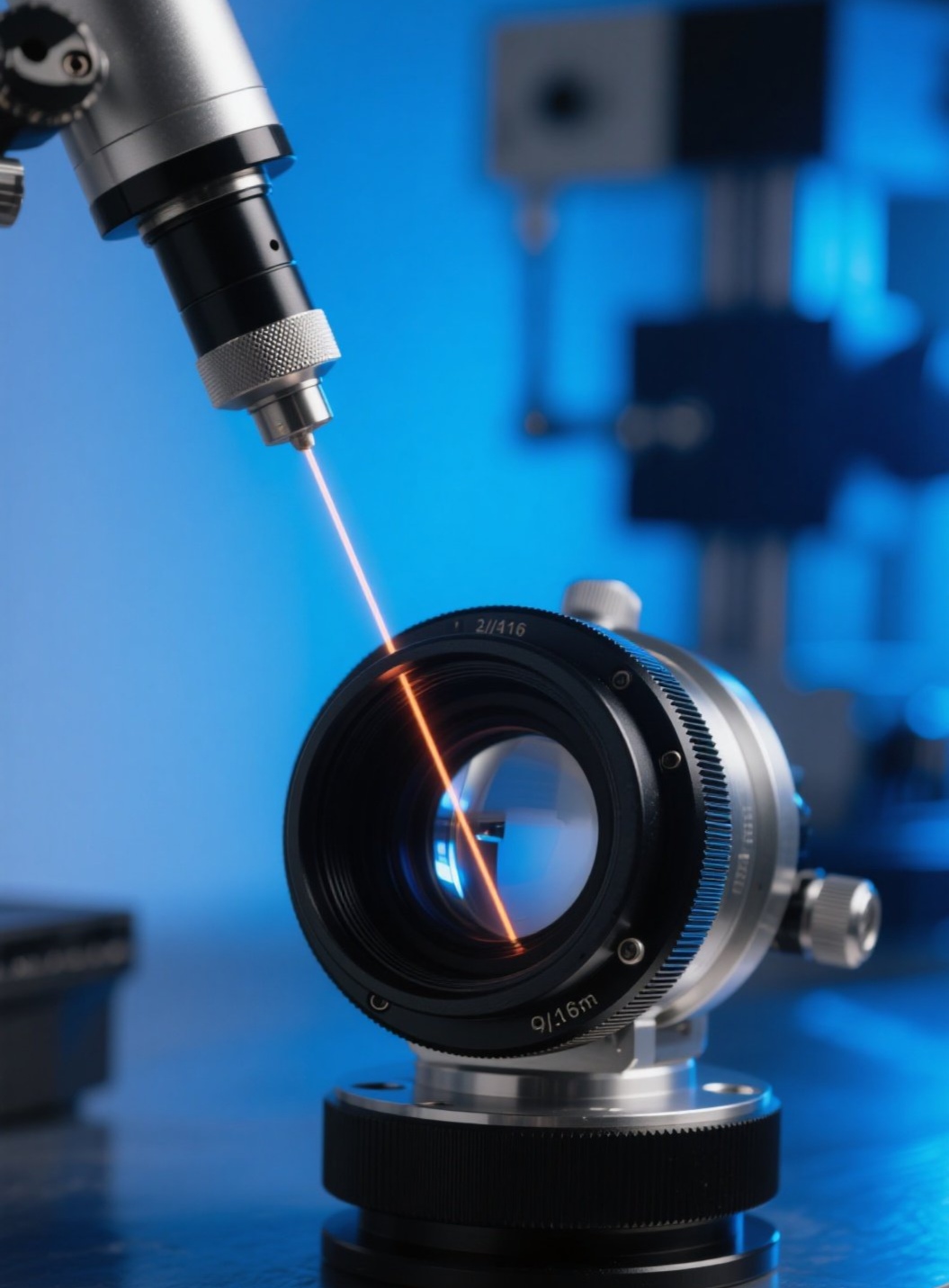

Optical instruments

Industrial automation

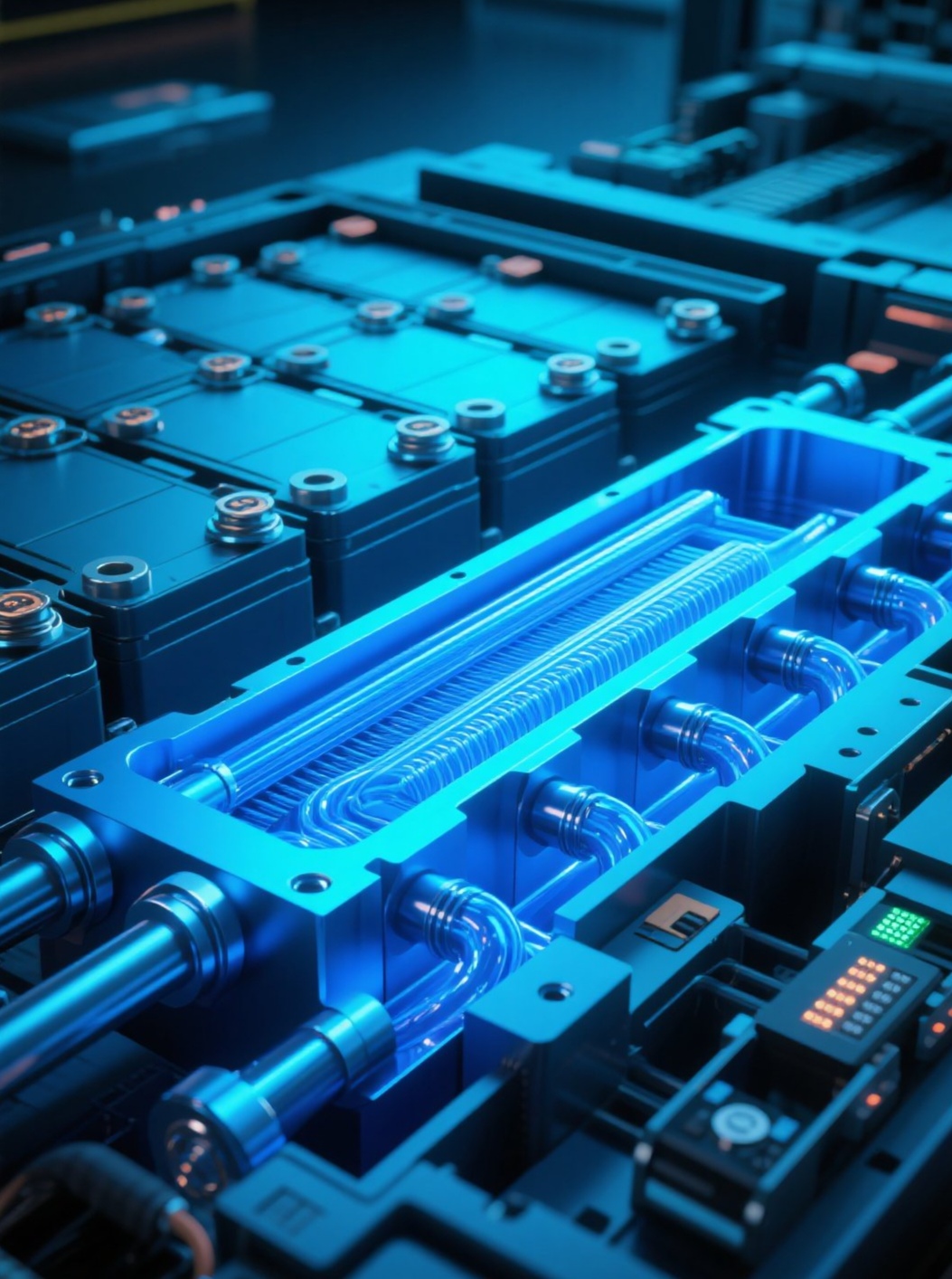

New energy

Science And Technology Robots

Instrumentation

luminaires

Smart Home Appliances

3C Digital

Our certificate

Our Happy Clients!

Customize the process

01

Accurate Assessment

Technical Docking + 72h feasibility confirmation

02

Transparent customization

Confidentiality agreements signed cost details

03

The sample is made intelligently

7-DAY proofing and synchronous material compliance certification

04

Mass production escort

Full record + Daily Progress Report + Urgent List Project

Frequently Asked Questions

Precision commitment: ± 0.003 mm precision control (60% over industry standard)

Swiss TORNOS walking machine + constant temperature workshop

Support to issue SGS full size inspection report

System commitment: the first full inspection + process sampling + final retest triple security

First piece of each batch (including test report number)

ISO9001 quality control process, yield ≥99.8%

Time Commitment: 7 Days Global Arrival (including customs clearance)

Set aside 20% capacity to deal with emergency orders

Launch of the greenlink project can be compressed to 5 days

Cost Commitment: material utilization 92% + (industry average 76%)

CNC intelligent layout system + residual material recovery

The list of consumables is transparent and traceable

Performance Commitment: Salt Spray test 1000h/wear resistance 100000 rpm