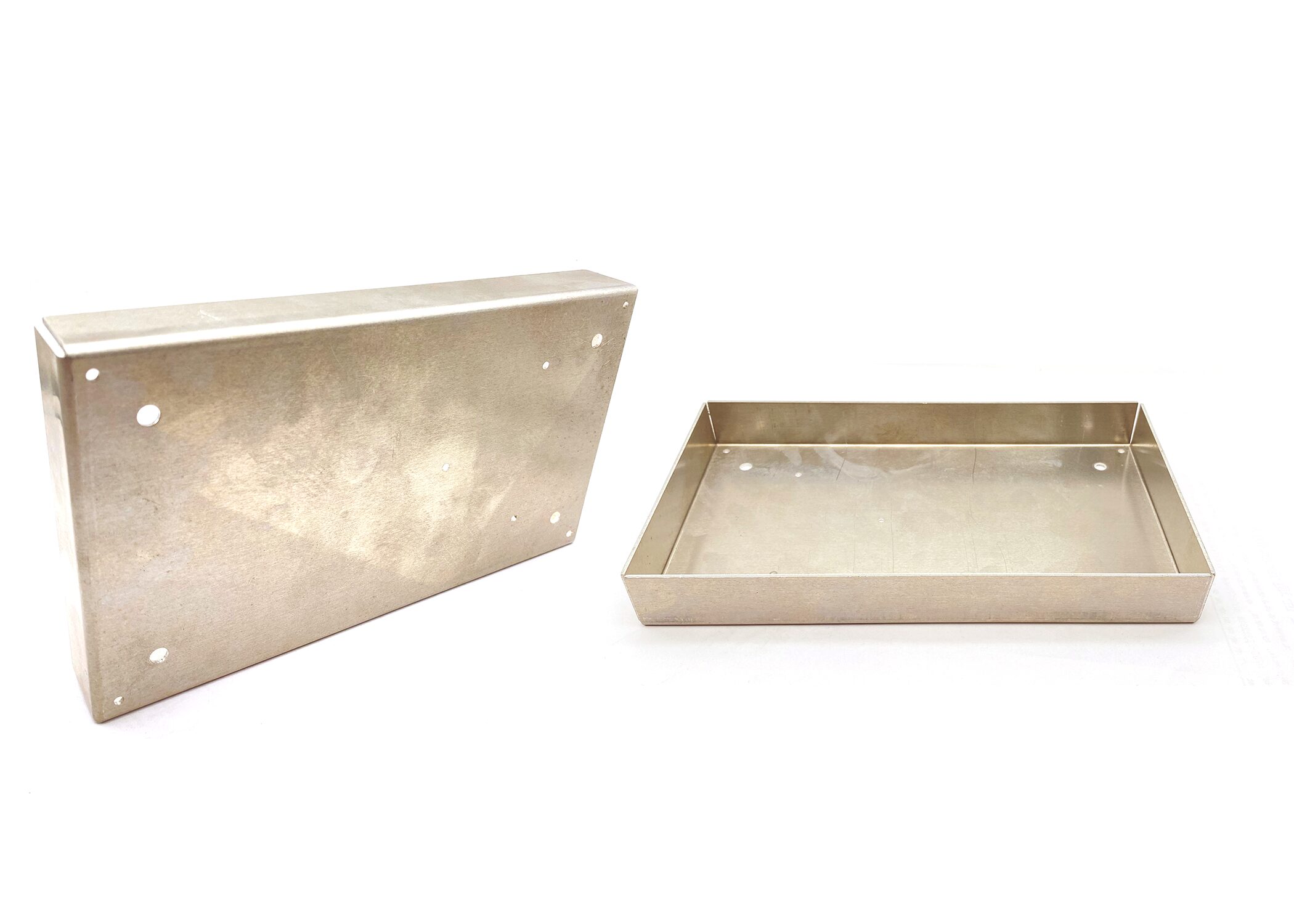

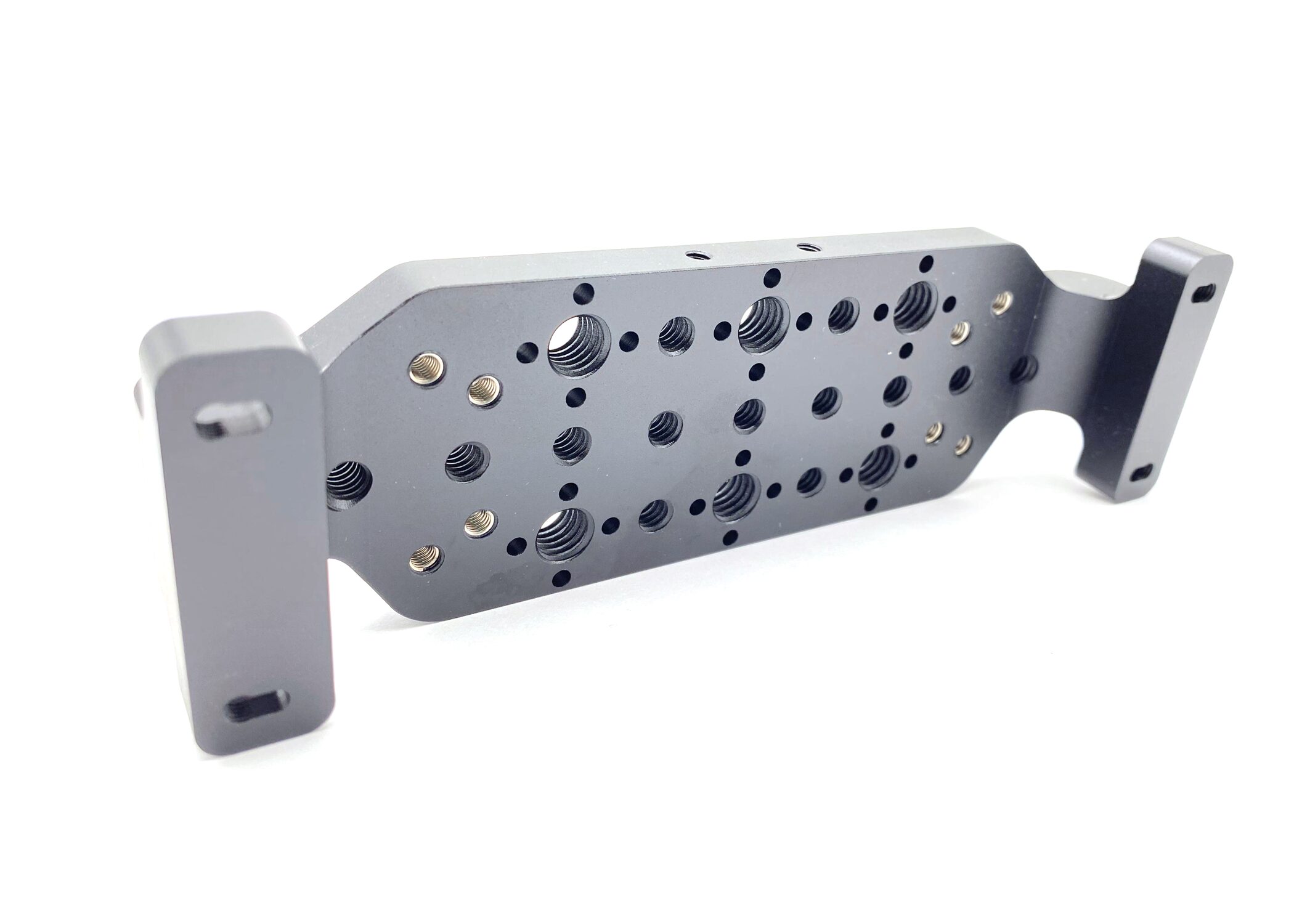

Stamping parts

✅ Zero-Burring Edges: Laser-cut blanking + Precision tooling

✅ Thickness Agnostic: 0.1mm shims to 12mm armor plates (SPCC/SUS/Al/Cu)

✅ Lean Logistics: 50-500T Presses x 15 Units, 20+ Die-Set Rotations/Day

✅ Full Assembly Ready: Deburring/Plating/EMI Gaskets pre-integrated

✦ IATF 16949 Automotive Grade ✦ 14-Day Mold Delivery ✦ 37 Yrs Metal Forming DNA”

Product Presentation

Have you encountered the following problems?

The problem of dimensional accuracy

Hole position shift screw stuck

Scrap of bending springback assembly

Out of control of rough precision of measuring tools

Surface quality defects

Seal failure due to Burr Scratch

Coating peeling salt spray perforation

Difficult to remove the appearance of indentation scrap

Insufficient properties of the material

Cracking of thin plate under load

Corrosion spread by material mixing

At your own risk if you do not have a certificate

Mold-related issues

The mold collapses the knife to stop the production to burn the Money

Tolerances are erratic and invalid in bulk

Maintenance failure yield diving

Assembly function problems

Screw hole dislocation nut suspended

Excessive spring clamping clearance

The plane is twisted and broken by force

Failure in special environment

Salt spray 72 hours perforation

High temperature deformation at 300 °C

Corrosion of chemical medium coating

Issue of delivery time of Supply

Production line paralysis due to delayed supply interruption

Batch wave assembly interruption

Urgent orders no door loss of orders

The problem of cost economy

Repeated repair and burn of inferior mould

Low Price, poor quality, expensive reworkAssembly

Hidden costs eat into profits

Our solution

Technology Breakthrough →5 times deformation customization

Multi-station machine for mass production of special-shaped parts with 5 times over-threaded head

Thinking of mass production → seamless connection of sample batch

Proofing is to produce according to batch standard and eliminate“Sample assassins”

Quality Control System → whole chain 99.8% yield

Three total + SGS/ROHS certification, support hydrogen embrittlement/salt spray 12 test

Production capacity guarantee →1 million grains per month

Large-scale production of non-standard parts, urgent single response does not jump ticket

Cooperation in good faith → rejection of orders beyond capacity

Be upfront about risks and don't take promises you can't make

Special material covering → military grade metal customization

C17200 beryllium copper/A286/titanium etc. 20 + special materials, with material report

Customize the solution according to your needs?

Why Us?

Can't find fit screws for special construction?

Our solution

Customized breakthrough: non-standard screw breakthrough size/thread/head type limit, 5 times deformation + 1990 mm super long parts cold heading forming, cost reduction of 30%

Application scenarios

New Energy Battery module special-shaped bracket screw instead of welding, weight reduction of 25% + save installation costs

Performance pull-out of screws under extreme conditions

Our solution

On-demand strengthening: military grade TA2 titanium corrosion resistance, SCM435 guarantee 12.9 true strength, A286 withstand 800 °C high temperature

Economic Value

Hydraulic system with custom screw life increased by 2 times, downtime loss of 20 million per year plus

Application scenarios

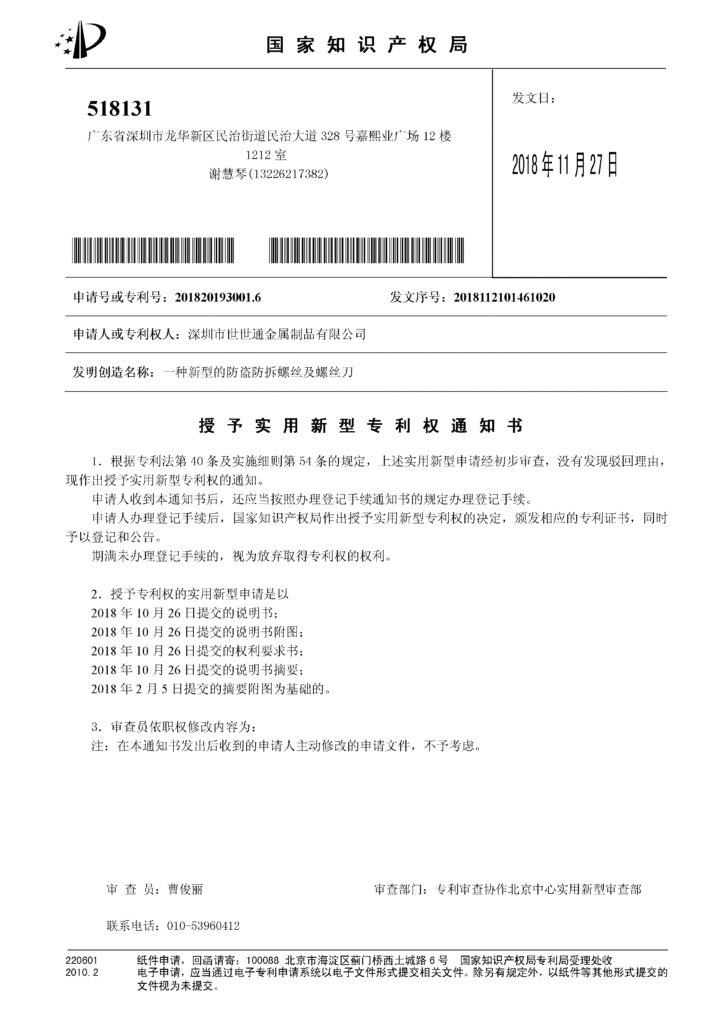

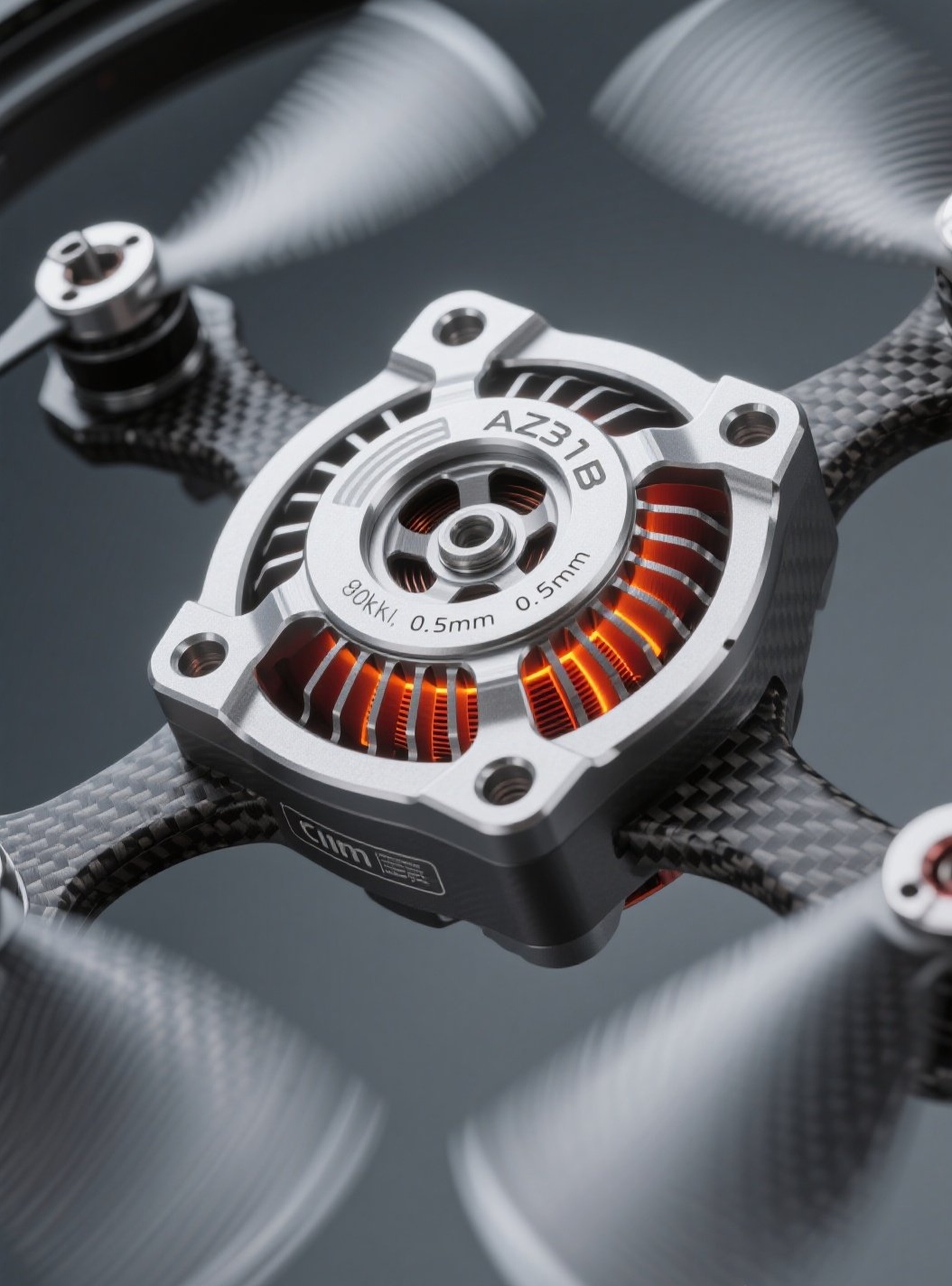

Intelligent automation

Drones

Robots

Medical equipment

Aerospace

Digital communication devices

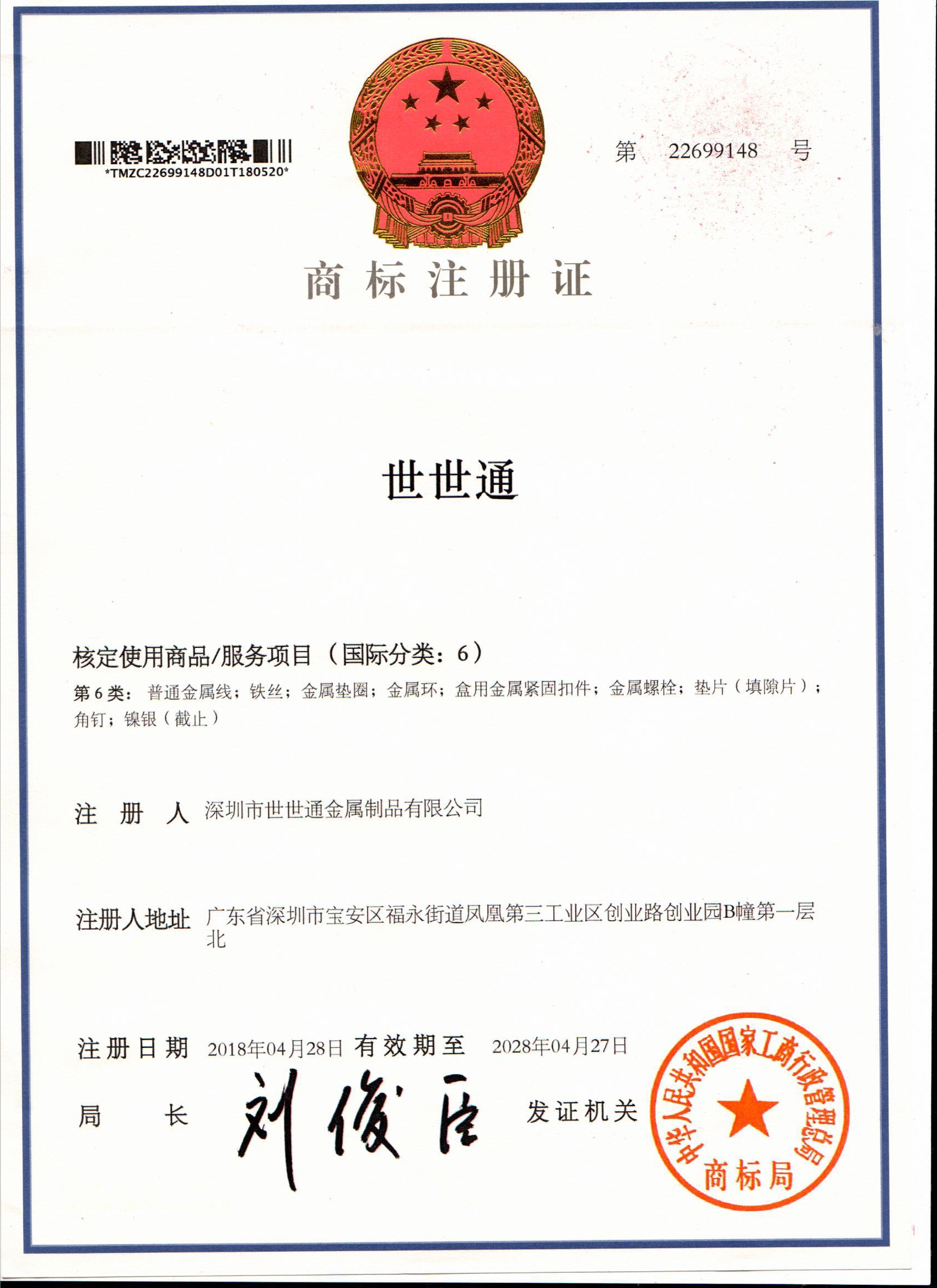

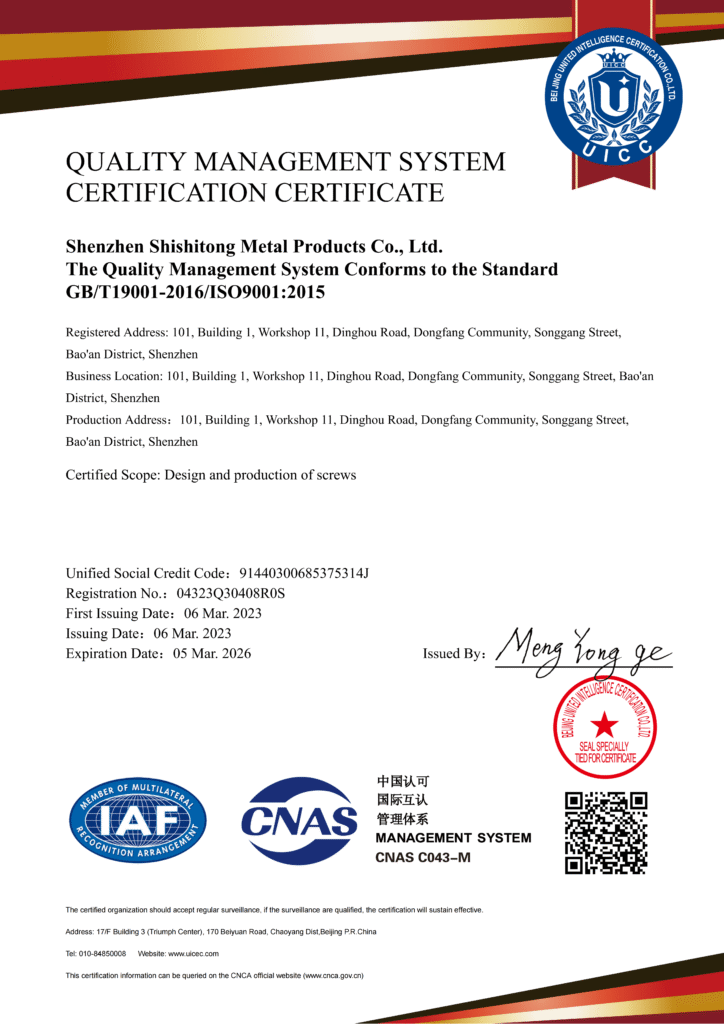

Our certificate

Our Happy Clients!

Customize the process

01

Demand Lock-in

specify size/material/finish/quantity

02

Design optimization

Cost reduction suggestion: change tolerance to save 20% | Increase R angle to prevent breakage | save time by using old model

03

Precise quotation

Integrated Process/cost assessment quotation

04

All In Cash

Collection that scheduling, 0 delay advance capital

05

Efficient production

Full chain quality inspection escort (99.8% yield)

06

On time delivery

Attached SGS Report + shipping inspection list

Frequently Asked Questions

Triple military grade quality control system

1 whole process quality inspection: first piece inspection + 30 minutes inspection + full inspection of shipment

299.8% guaranteed yield (industry average < 90%)

3 support SGS/ROHS certification, provide salt spray 300h report + 12.9 hardness report + hydrogen embrittlement test and other 8 test documents

We adopt a stepped extreme speed response

1. Expedited orders: lead time ≤3 days, complete lead time 7-10 days.

2. Regular orders: lead time ≤7 days, complete lead time 10-15 days.

(note: 1990 mm extra-long parts are also applicable when all dies/materials are available)

The world’s only breakthrough technology

1 length: measured support 1-1990 mm (industry upper limit 300 mm)

2 anti-bending: Exclusive fixture heat treatment, 500 mm below 0 bending, long pieces of straightening ± 0.05 mm

3 material: stainless steel/iron/copper/aluminum/titanium full support

Full coverage of authentication matrix

1 quality system: ISO9001 + IATF16949

Environmental certification: SGS + ROHS + REACH

3 strength certification: 12.9 hardness CNAS test report

Behind the premium is a cost revolution

1. Material loss: peer practice > 10% , our breakthrough < 0.2% (full stop defective)

2. Rework rate: peer practice 30% (bending deformation) , our breakthrough 0 rework (exclusive bending technology)

3. Salt spray cost: peer practice 48h namely Rust, our breakthrough 300h maintenance-free (military grade coating)

The Math: 15% higher purchase cost, 300% longer life + 60% lower maintenance cost