Nuts and gaskets

✅ Anti-Seize Defense: DacroShield™ coating nuts with crush gaskets (RT to 800℃)

✅ Vibration Lock: All-metal lock nuts >1,200Nm preload (vs nylon decay)

✅ Fluid-Tight Seals: Helicoid/Octagonal gaskets @ 690bar (API 6A Annex F)

✅ Full Kit Traceability: Laser-marked lot numbers + Material Certs per DIN 267

✦ AS9100/API Q1 Certified ✦ 7-Day Kitting ✦ 37 Yrs Sealing DNA”

Product Presentation

Have you encountered any of these problems?

Out of control in microns

Temperature fluctuation 0.02 mm, early morning shipment evening scrap

Structural deformation

Mini special-shaped eccentric, thread bite degree is all up to luck

Hot and cold crack by turns

After three cycles from-30 °C to 200 °C, the subsurface cracks were not detected

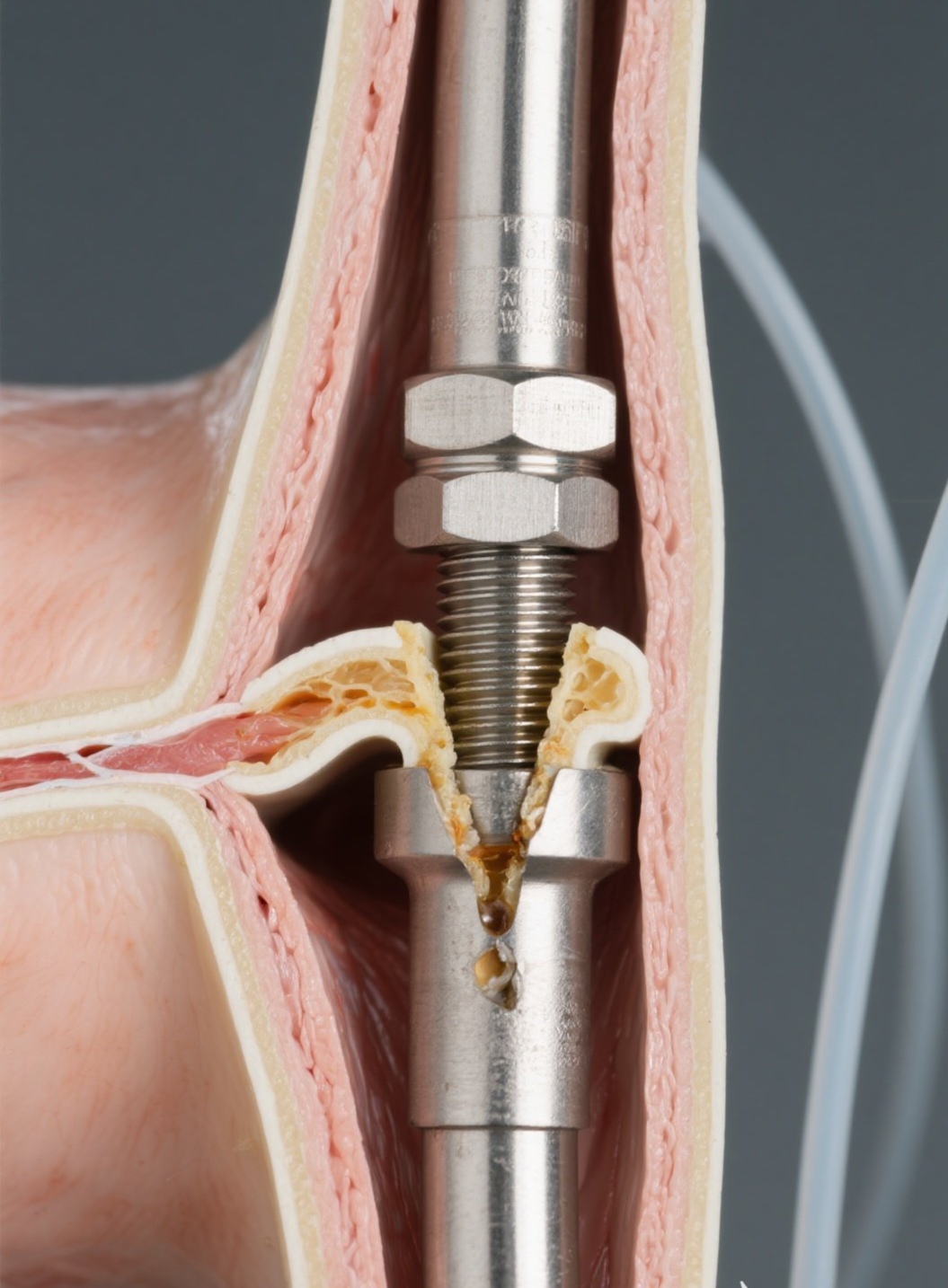

Little medical damage can kill

Coaxial deviation of catheter connector 0.03 mm = risk of in vivo leakage

Our solution

Microsecond control

± 0.003 mm, zero sense of temperature difference between day and night

Zero deformation of irregular shape

3D simulation path + military fixture, 30% efficiency feedback accuracy

Zero risk of leakage

The coaxiality of medical components was more than 99.9%

Full perspective of a cleft

After three cycles of-30 °C200 °C, submicron cracks can not escape

Customize the solution according to your needs?

Why Us?

Nut selection for fatal scenes

Anti-loose fighter

8 Tremors 0 loosing, New Energy Equipment Jedi rebirth

Corrosion Terminator

After immersion in seawater for 3 years, the titanium alloy threads are as smooth as ever

The Space Grabber

2 mm ultra-thin flange, turning the dead angle precision lock

Cut off the chain of quick profits

32 days delivery →7 days, 37% straight cost reduction record

Shim Selection Life and death choice

Leaky black hole plug

Medical micro-pad > 99.9% sealed, 0 anesthesia failure

Stress assassin retreat

300 tons of stamping parts 0 deformation, precision surface protection

The cost of assassins dying

One set of gasket saves 3 processes, saving 800,000 yuan per year

Application scenarios

The heart of the car

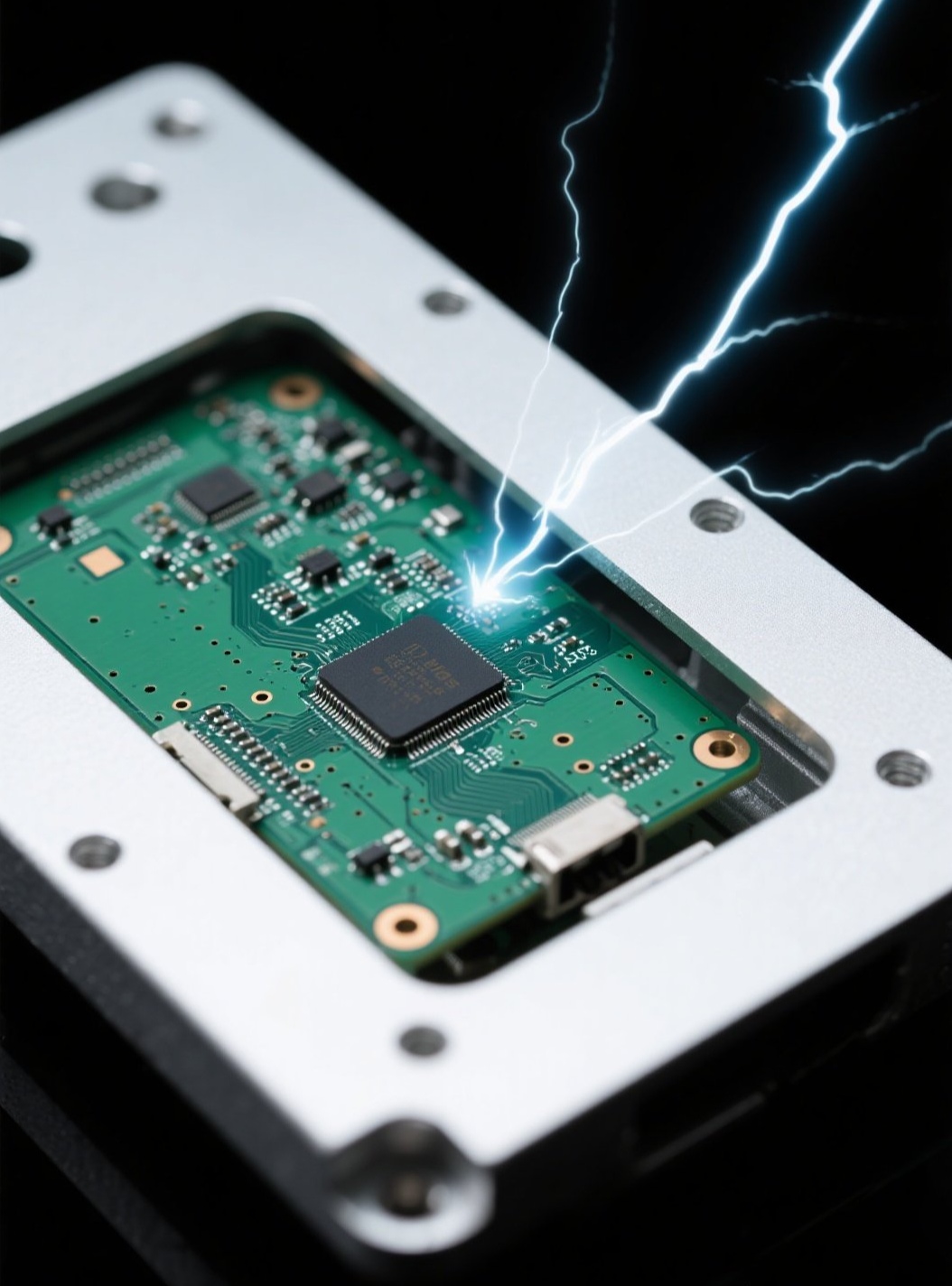

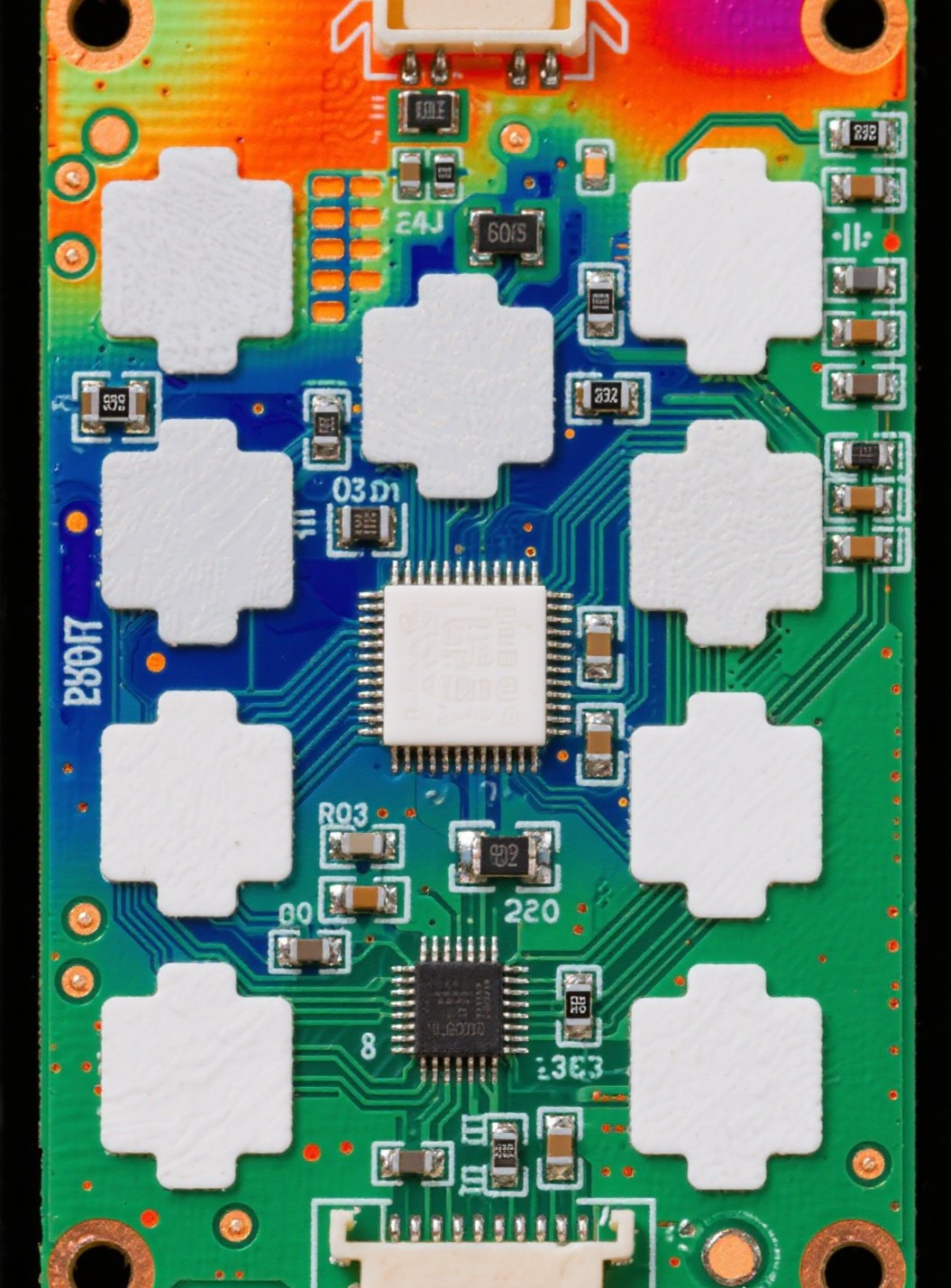

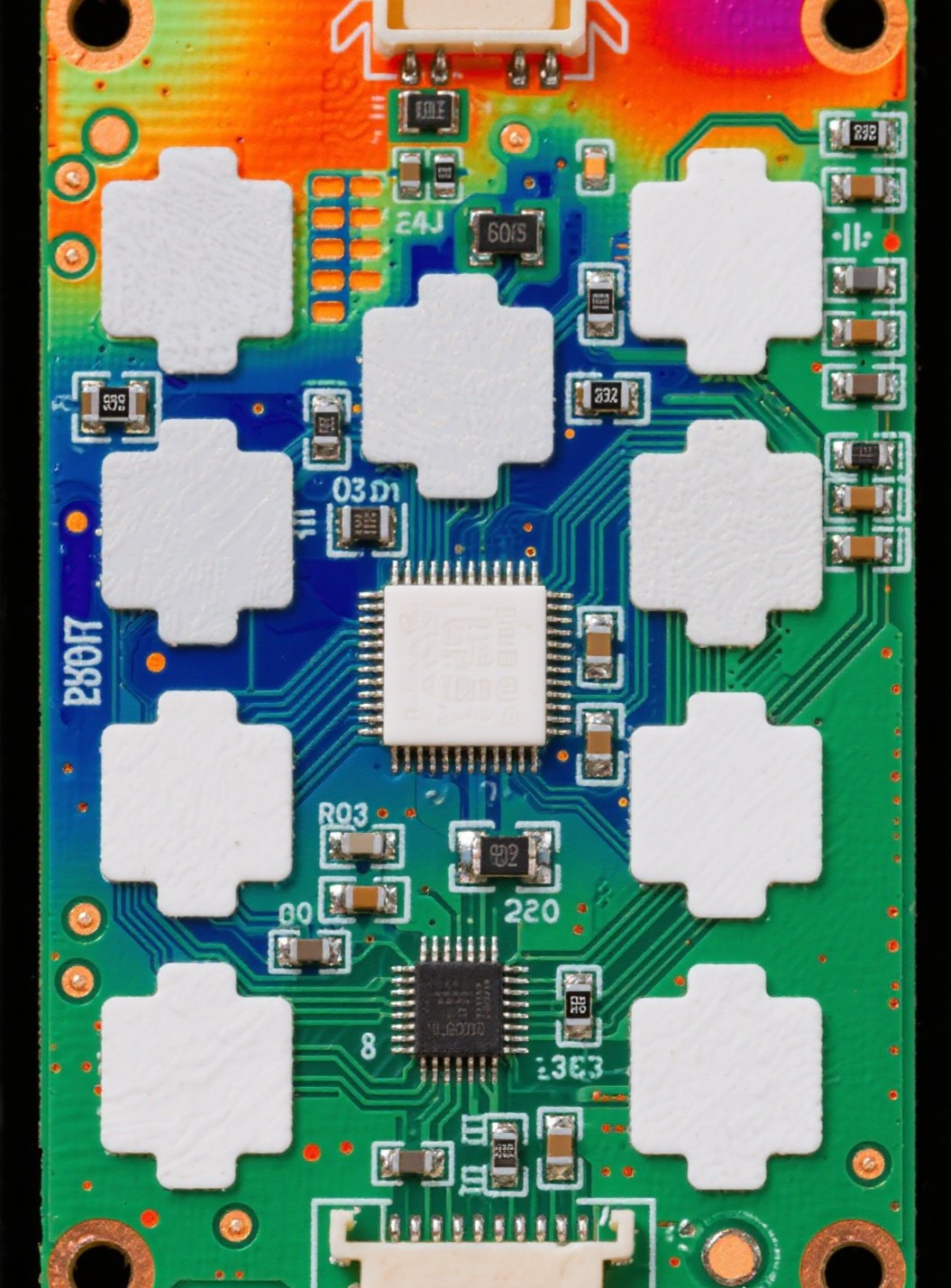

Electronic precision stitching

Optical micrometer calibration

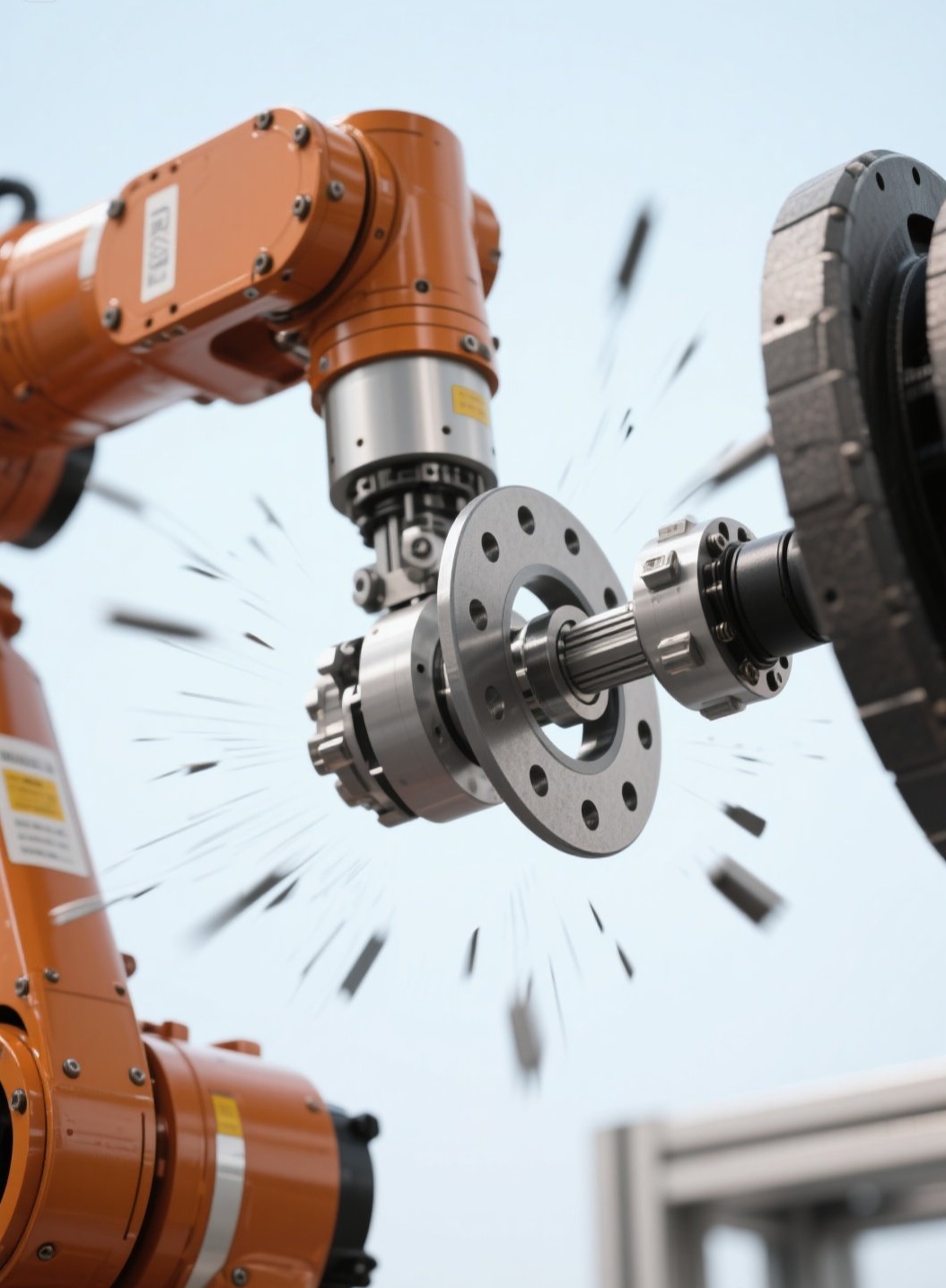

Pressure on robot joints

Limit packaging of energy storage box

Lifeblood of minimally invasive medicine

Diamagnetic boundary of instrument

Intelligent Electric Heat Wave Line of defense

3c space plunder

Automated Death Challenge

Our certificate

Our Happy Clients!

Customize the process

01

Second Lock required

30 minutes to dismantle drawing blind spots, german simulation pre-check interference points, save 65% trial and error costs

02

Cost Transparency Bureau

The quotation includes the customs tax code traceability, confidentiality/material cost/logistics fee one-click White Box

03

The wall of sample is broken

Delivery of pre-inspection report with SGS within 3 days, synchronous FDA Ingredient Certificate for medical grade gaskets

04

Mass-produced nuclear explosions

First Laser File + 72h shipment, emergency Order Activated Military Green Channel

Frequently Asked Questions

Nano-locking:

▸ German ± 0.003 mm (peer > 0.02 mm)

▸ measured thread fit: 80 Nm torque 0 slip

Third-order circuit breaker:

1. Full-scale laser modeling of the first piece → Generation of digital twins

2. Every 100 pieces of spectrometer material test → exceed the standard automatic production

3. Final salt fog box abuse test →2 times over order requirement

Military-industrial response:

€ ¢ 72h lightning channel: North n Energy Storage Order placed by Tuesday â € ¢ arriving at port on Friday (customs serial number available)

▸ panic preparation: 20 tons of TC4 titanium ingots + 500,000 pieces of medical device-grade gasket materials

Formula for material slaughtering:

Cost = (weight of titanium ingot x $28)-scrap recovery deduct $6

KIT system: CNC cutting error < 0.08 g → utilization rate of 92% (industry average 67%)

Corrosion Kill Solution:

▸12-layer protection: zn-ni alloy + micro-arc oxidation → salt spray 2000h record

▸ nuclear grade test: X-ray inspection per gasket → voids > 0.1 mm are scrapped