CNC

Optimize Your CNC Machining with Precision Fasteners. Source high-tolerance screws, bolts, washers & inserts specifically engineered for demanding CNC fixtures, jigs & manufactured components. Enhance stability & efficiency.

How to break through these industry parts processing problems?

Inconel 718 fuel nozzle special-shaped flow channel processing

thin-walled components of Hastelloy C276 nuclear reactor seal rings

1J85 alloy MRI equipment magnetic shielding capsule integrated molding

CNC machining of aviation parts

Custom parameters

🔹Stainless Steel: food grade stainless steel, environmental testing reports such as SGS/ROHS/REACH can be provided. Other materials can also be customized, such as carbon steel, aluminum, titanium, brass and so on.

🔹Surface Treatment: passivating, salt spray time up to 1000 hours, strong corrosion resistance.

🔹Tailor-made: suitable for assembly of ultra-precision instruments to meet tolerance requirements.

We use state-of-the-art equipment

We use advanced technology

Customization of product application scenarios

Type:sleeve, gear, coupling

Material: GH4169/4J36/Monel K500

Industry:aerospace engines, industrial robot joints

Type: valve body, pump casing, flange fittings

Material:Hastelloy/Inconel 625/Monel400

Industry:Chemical Reactor, seawater desalination pipeline system

Type:Magnetic Yoke, sensor housing, shield

Material:1J79 / 1J22 / 4J29

Industry: MRI medical equipment, high-energy physics experimental devices

Why are our CNC parts more reliable?

Core competencies | Technical parameters/comparative advantage | Customer value |

Machining of extreme materials | GH4169 superalloys with machinable hardness HRC ≥45 | Avoid heat treatment deformation, extend the life of parts 3 times |

Ultra-precision tolerance | Five-axis machining accuracy ± 0.005 mm, Ra0.2 Surface finish | Reduce assembly loss and equipment failure rate |

Forming of complex structure | Support Deep Hole (diameter-depth ratio 1:15) , thin-walled (0.3 mm) processing | Instead of multi-process welding, the cost is reduced by 40% |

Build Your Custom Solution in 3 Steps

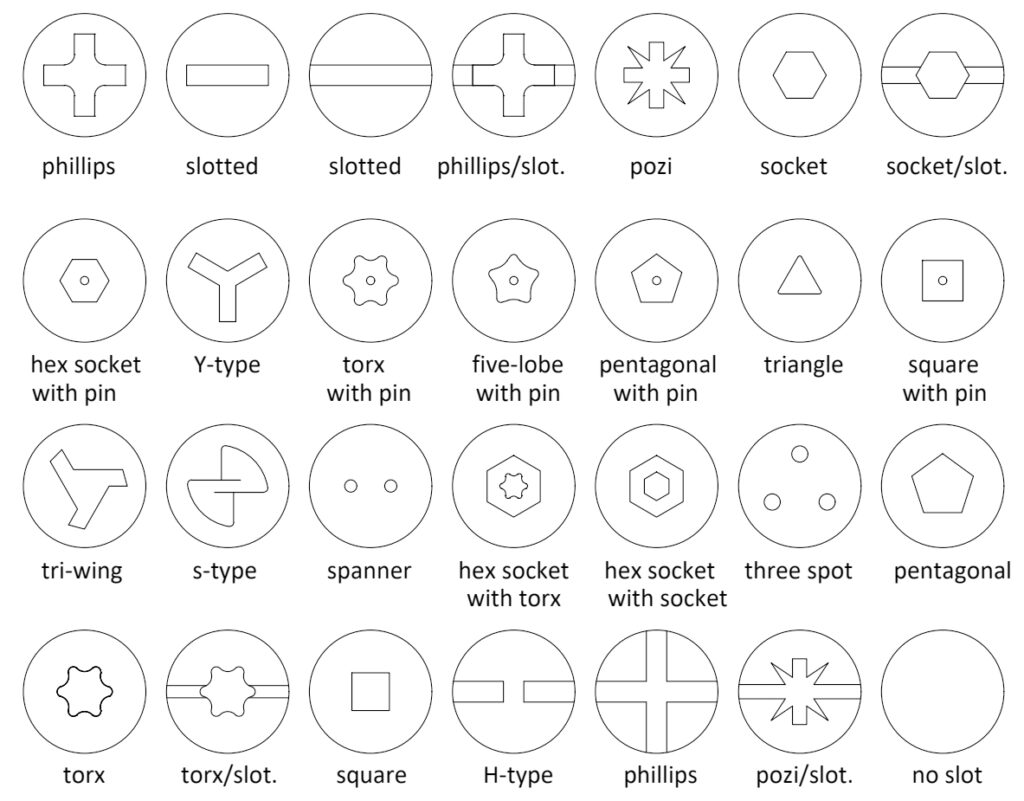

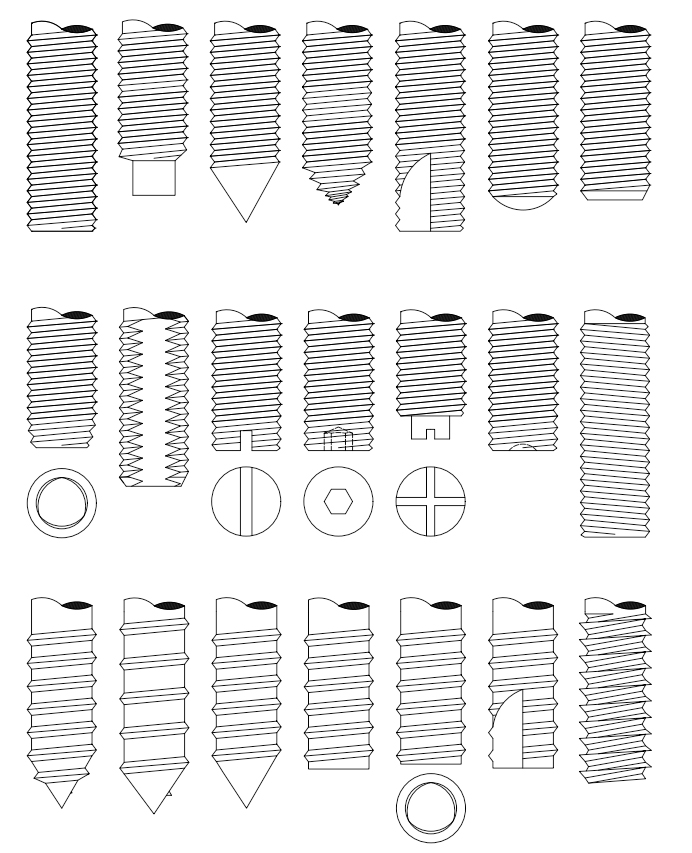

1. Select Your Groove Type – Optimize for Strength or Flexibility

Choose from 10+ engineered groove profiles – from standard V-grooves for general applications to specialized T-slots for heavy machinery.

Our CNC machining ensures ±0.005mm tolerance for perfect load distribution.

Pro Tip: 90% of industrial clients select helical grooves for vibration resistance.

2. Choose Tooth Type: Precision Cutting or Smooth Engagement

Select triangular teeth for high-speed cutting (ideal for aerospace alloys)or rounded teeth to reduce wear in repetitive assembly (common in automotive).

Custom tooth pitch options available – Our engineers recommend 2.5mm pitch for 80% of polymer applications.

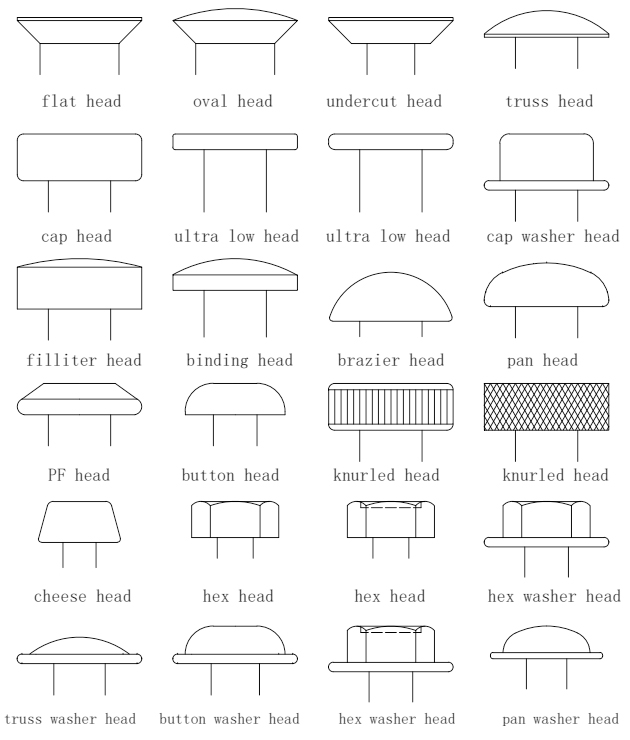

3. Design Your Head Shape: Functional Aesthetics Meets Installation Efficiency

From low-profile hex heads (ISO 4762) to tamper-resistant Torx designs, select shapes that align with your tooling ecosystem.

Pro Tip: 70% of clients pairing button heads with recessed grooves reduce installation time by 40%.

Precision-engineered from concept to delivery: Streamlined 5-stage process with 1-hour response, 72h prototyping, and ISO-certified quality control.

1.Upload Drawing

Submit CAD/PDF drawings or send samples online.

2. Your request

Shape, material, surface finish, quantity, size。

3. Rapid Prototyping

CNC precision machining + 3D printing synchronous start-up, 72 hours to deliver functional samples。

4. Provide a report

To provide you with a customized product inspection report and production cost forecast.

5. Mass Production & QC

The whole process of digital production, every 500 pieces of full inspection once, support SGS third-party inspection, 7-15 days to complete order delivery.