Medical-grade screw customization specialist

Precision, Cleanliness & Reliability for Medical Device Fastening. SST provides biocompatible, non-magnetic & corrosion-resistant screws and miniature fasteners meeting stringent standards for critical medical equipment applications.

Dedicated standards for medical devices

Support FDA 510(K)/CER MDR certification, preferred supplier of orthopaedic implants/endoscopes/imaging equipment

Dedicated standards for medical devices

✅ Implantable clean room: ISO Class 5 clean environment

✅ Whole process traceability: each screw is individually UDI coded

✅ Sterilization support: oxirane gamma rays high pressure steam

Why did Medtronic choose our cytotoxicity test?

PASS ISO 10993-5 cytotoxicity/ISO 10993-10 stimulation allergy test suite, support third party retest

Medical testing system

1.Detection of heavy metals in raw materials by ICP-MS

“ICP-MS accurate screening, 23 heavy metals exceeded zero”

2.Process particulate control < 100 particles/M 3

“Dynamic cleaning monitoring, particle count < 100/m3 to ISO 5”

3.Sterility test of finished product

“Oxirane validation, zero bio-load detected.”

Medical optimization techniques

🔹Anti-fretting corrosion: Anodic oxidation + titanium nitride composite coating

🔹Non-slip tooth design: double-headed triangle thread (patent no. ZL2023XXXXXXXX)

🔹Rapid Response: 48-hour emergency sample delivery

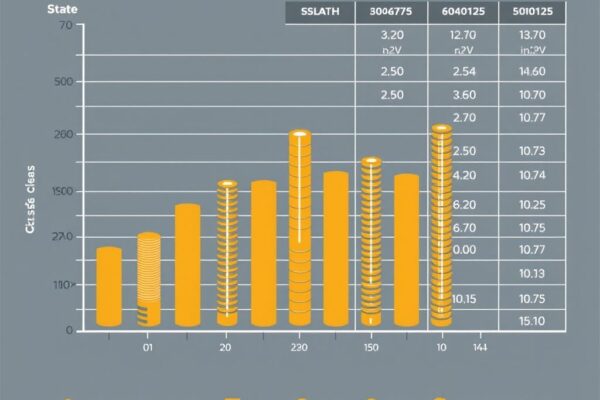

Parameters | Conventional turning | The technology of walking heart machine |

Cost | ¥15.8 per piece | ¥9.3 per piece |

Production rate | 80 pieces per hour | 500 pieces per hour |

Surface Roughness | Ra1.6 | Ra0.4 |

More stringent cleanliness promises than the operating room

12-hour root cause analysis, 72-hour global replacement in place for unexpected recalls

Exclusive Medical Insurance

🔹 Free Biocompatibility test template

🔹 Annual Quality White Paper for strategic customers

🔹 Support VHP sterilization packaging customization

Emergency level | Response time | The solution |

Type one recall | 1 hour | Full batch replacement + public notice |

The second kind of bad | 4 hour | Emergency deployment of regional inventory |

Type 3 complaints | 8 hour | Door-to-door inspection by technical team |

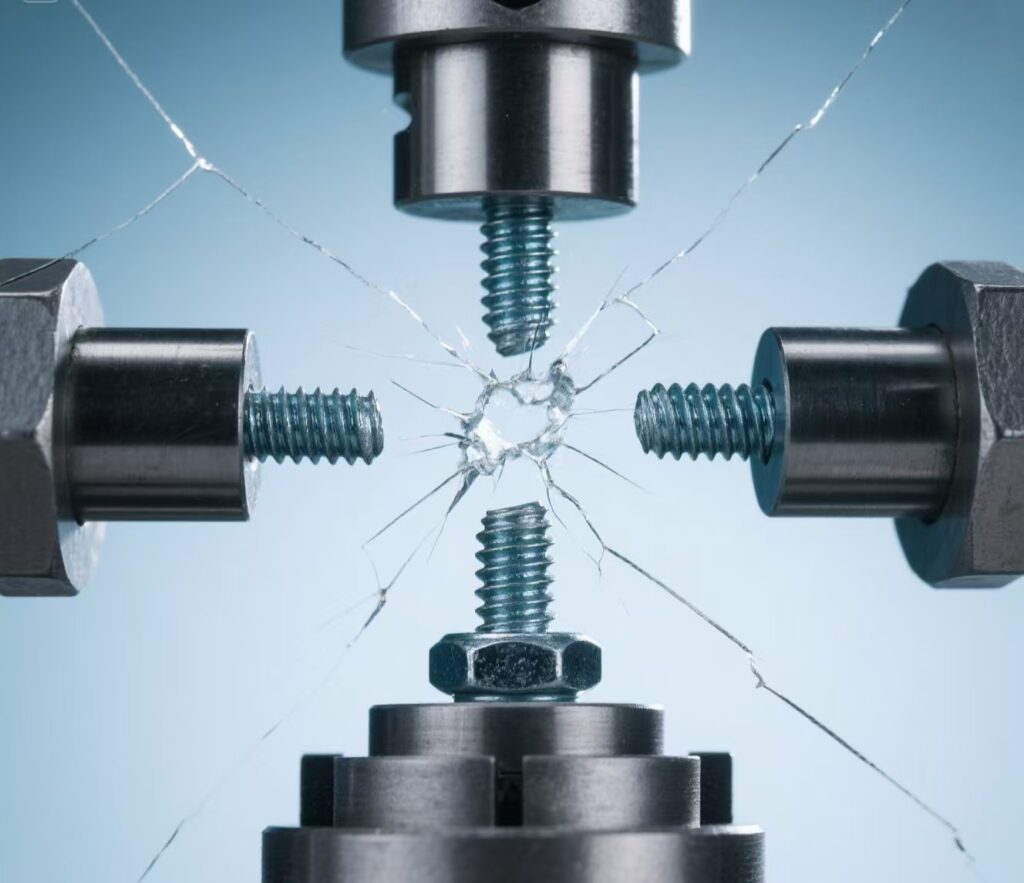

Strict Quality Control

36 years general work team check, 100% simulation of actual combat environment, from the source to eliminate the risk of broken head/sliding teeth.

Data Detection

We will carry out a lot of screw products sampling test, to ensure that customers get our qualified products.

100,000 class clean workshop live broadcast, witness the birth of medical screws

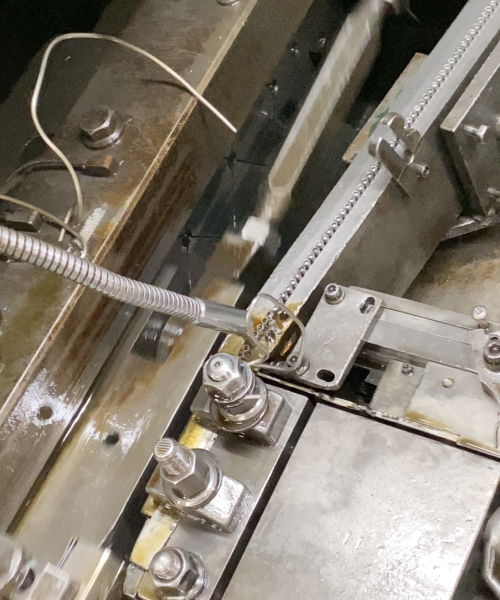

German B + S automatic lathe + American Hubbard ultrasonic cleaning line, accuracy exceeding ISO 13485 standard

Standards for medical intelligence

✅Implant roughness ra 0.8

✅particulate contamination < 5 μm

✅< 10 cfu/g of initial contaminating bacteria in packaging

✅Material: titanium material, food grade material

✅Dimensions: tolerance ± 0.1 mm

✅Smooth appearance, beautiful, finish ≤0.8

✅Environmental Protection: food grade

Support MDSAP multi-national certification to meet China, US and EU market access

Production Process

Intelligent optimization process, precision intelligent manufacturing each fastener

The price dropped 60% from first prototype to million-dollar production

Sample free verification (limited to Class III medical devices) , the annual strategic customers enjoy QC services in the factory

Health care purchasing commitment

🔹10-year warranty period

🔹2 quality issues 48-hour global replenishment

🔹3 free of charge to provide sterilization verification report

The 2023 flew through the FDA to check for zero defects

01.

Material cost accounted for 38%

02.

clean process 27%

03.

etection cost 22%

04.

Profit 13%

Custom Pricing

Free sample verification, maximum 15% refund after mass production, product price commitment signed online

Stage | Unit Price | Lead Time | Exclusive rights and interests |

Samples (1-10) | $ XX.XX | 3 days | Free of mould fee |

Small Batch (1000) | $ XX.XX | 7 days | Send the Destructive testing |

Mass production (100,000 +) | $ XX.XX | 15 days | General factory acceptance in factory |

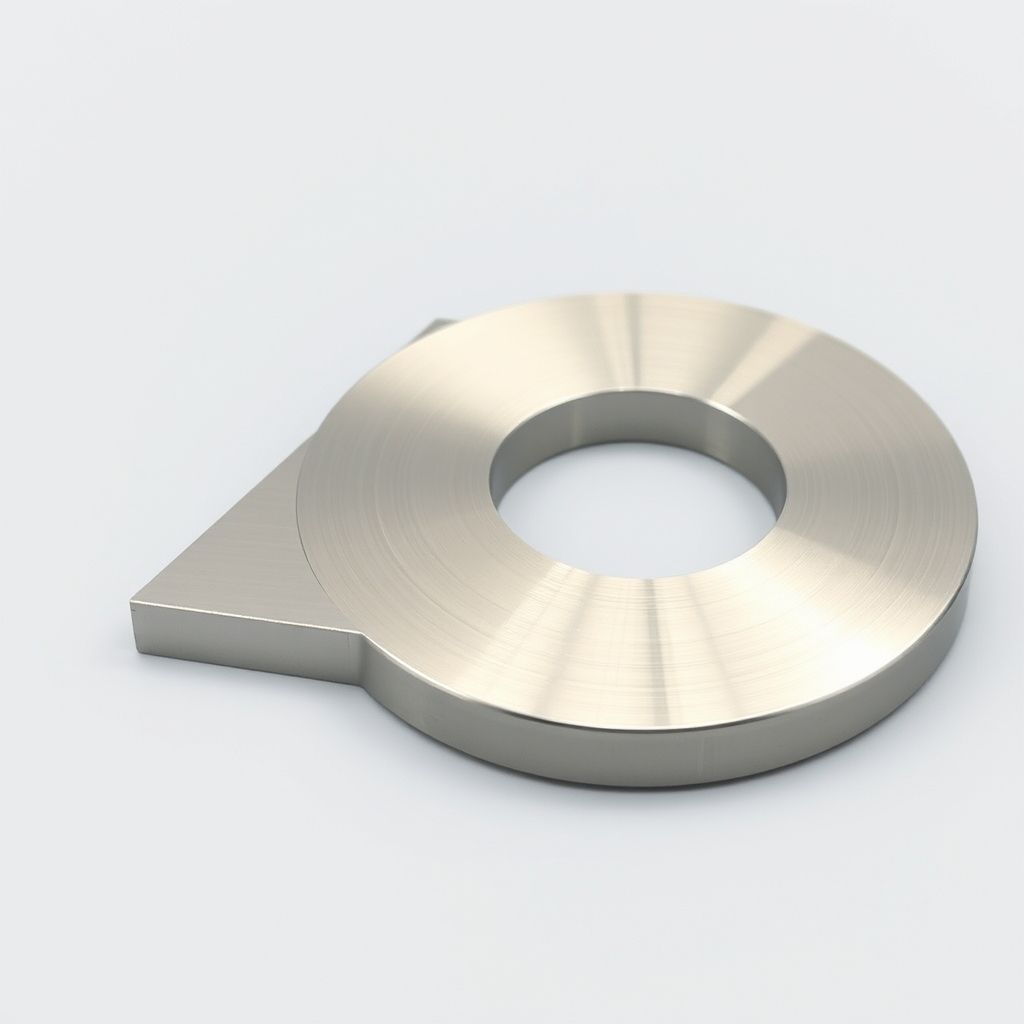

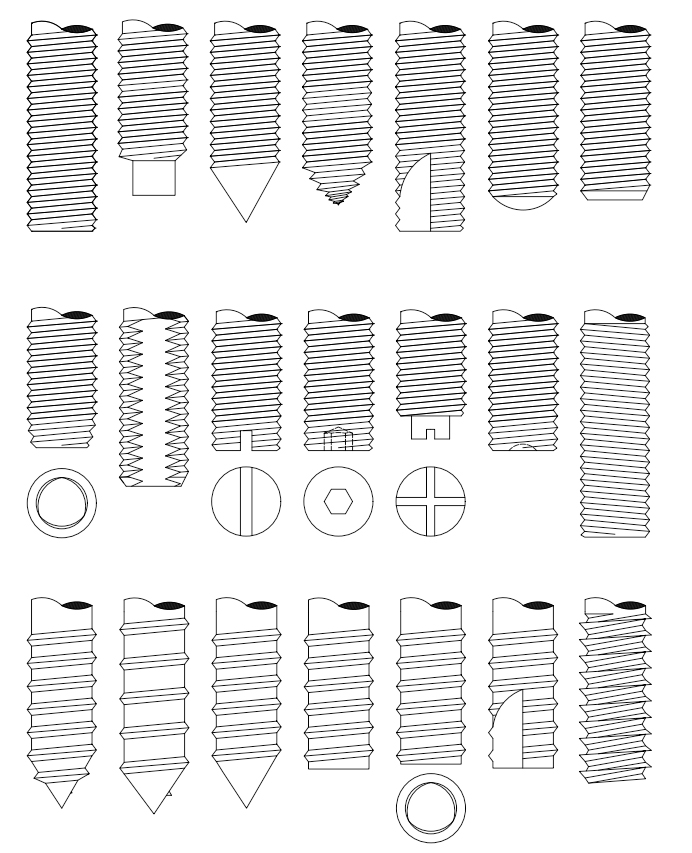

Products

Build Your Custom Solution in 3 Steps

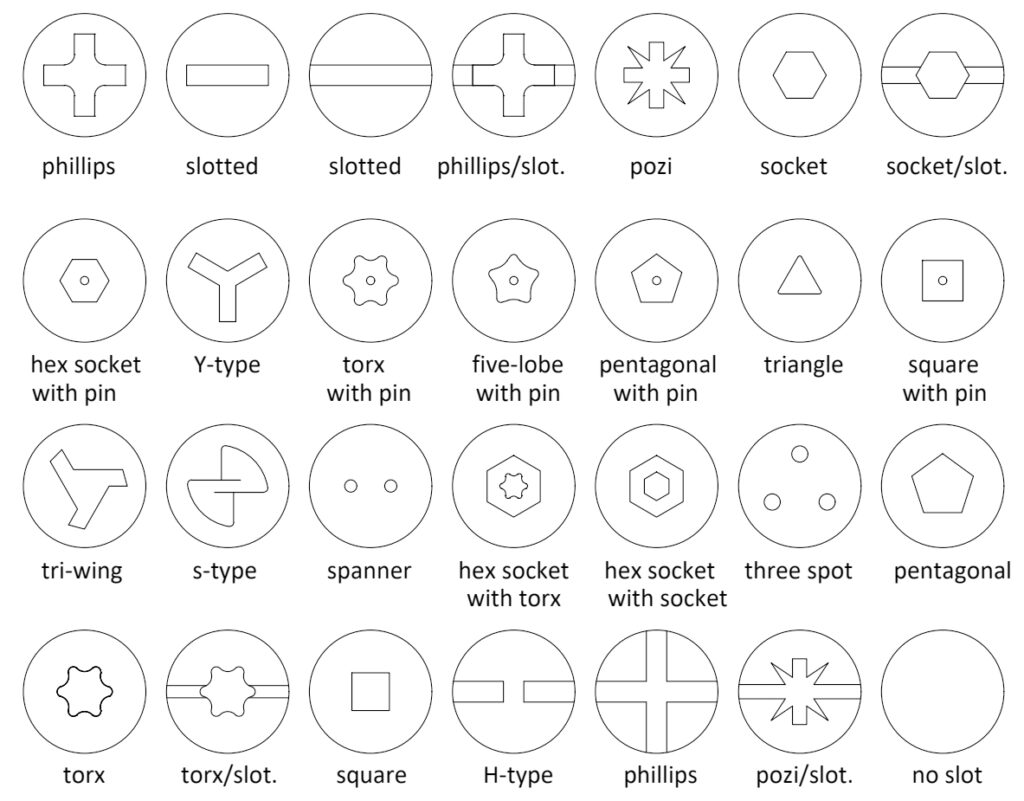

1. Select Your Groove Type – Optimize for Strength or Flexibility

Choose from 10+ engineered groove profiles – from standard V-grooves for general applications to specialized T-slots for heavy machinery.

Our CNC machining ensures ±0.005mm tolerance for perfect load distribution.

Pro Tip: 90% of industrial clients select helical grooves for vibration resistance.

2. Choose Tooth Type: Precision Cutting or Smooth Engagement

Select triangular teeth for high-speed cutting (ideal for aerospace alloys)or rounded teeth to reduce wear in repetitive assembly (common in automotive).

Custom tooth pitch options available – Our engineers recommend 2.5mm pitch for 80% of polymer applications.

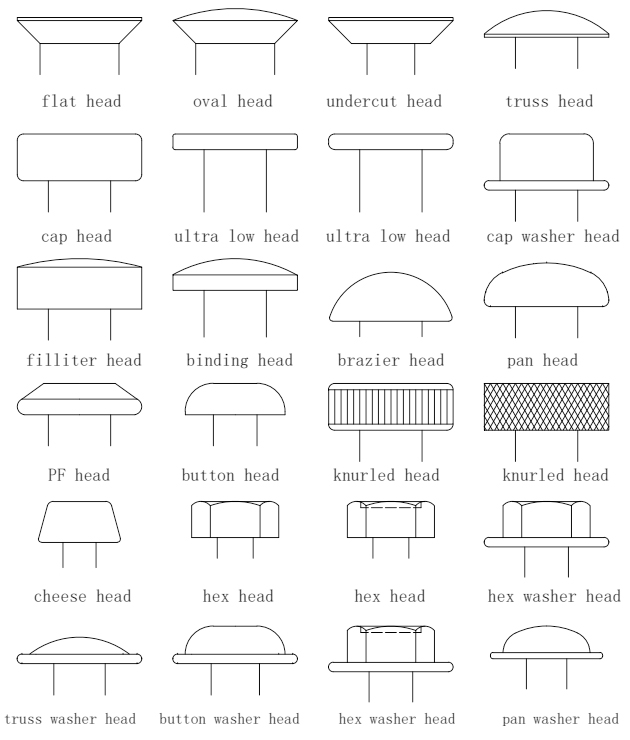

3. Design Your Head Shape: Functional Aesthetics Meets Installation Efficiency

From low-profile hex heads (ISO 4762) to tamper-resistant Torx designs, select shapes that align with your tooling ecosystem.

Pro Tip: 70% of clients pairing button heads with recessed grooves reduce installation time by 40%.

Precision-engineered from concept to delivery: Streamlined 5-stage process with 1-hour response, 72h prototyping, and ISO-certified quality control.

1.Upload Drawing

Submit CAD/PDF drawings or send samples online.

2. Your request

Shape, material, surface finish, quantity, size。

3. Rapid Prototyping

CNC precision machining + 3D printing synchronous start-up, 72 hours to deliver functional samples。

4. Provide a report

To provide you with a customized product inspection report and production cost forecast.

5. Mass Production & QC

The whole process of digital production, every 500 pieces of full inspection once, support SGS third-party inspection, 7-15 days to complete order delivery.