The field of military industry

Mission-Critical Fasteners for Defense & Aerospace Standards. SST supplies rigorously tested, compliant screws, bolts & hardware meeting MIL-SPEC & stringent military/aerospace requirements for reliability in demanding environments.

Exclusive services in the military field

military grade material processing capacity

TC4 titanium alloy/A286 superalloy/17-4PH, etc.

Military Security Production Workshop

independent 1200M2 Security Workshop.

Extreme environment verification

– 60 °C ~ 1200 °C environment simulation test-RRB-

Special surface treatment process

micro-arc oxidation/vacuum plating/anti-electromagnetic interference treatment

Military standard testing system

GJB9001C-2017

Service flow of military industry

Mil-Spec Analysis

Mil-Spec Requirement Review

Confidential Agreement

Classified NDA Signing

Combat-Grade Sourcing

Military-Grade Material Selection

actical Engineering

Special Process Development

Strategic Sampling

Small-Batch Validation

Military Archiving

Full Inspection & Storage

rmored Transport

Secure Logistics

attlefield Tracking

Field Performance Tracking

Tabular layouts of technical parameters of military industry

Indicators | Military standards | Conventional standards |

Material Strength | Maximum 14.9 | Normal 8.8 |

Temperature Range | -60 °C ~ 1200 °C | -20 °C ~ 400 °C |

Salt spray test | 1000h no corrosion | 72H standard |

Tolerance accuracy | ± 0.005 mm | ± 0.03 mm |

Tensile strength | 1600 MPA | 800 mpa |

Electromagnetic compatibility | Mil-std-461g | No special requirements |

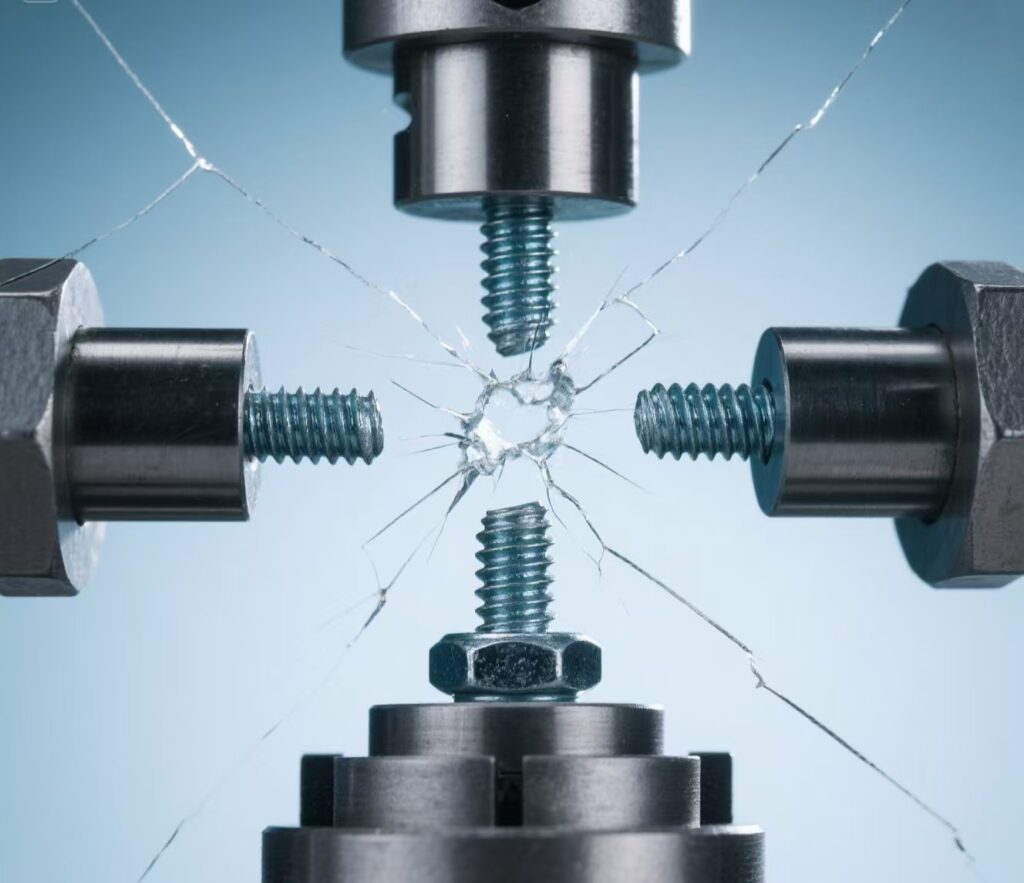

Our strict quality control of our products

36 years general work team check, 100% simulation of actual combat environment, from the source to eliminate the risk of broken head/sliding teeth.

Data detection

We will carry out a lot of screw products sampling test, to ensure that customers get our qualified products.

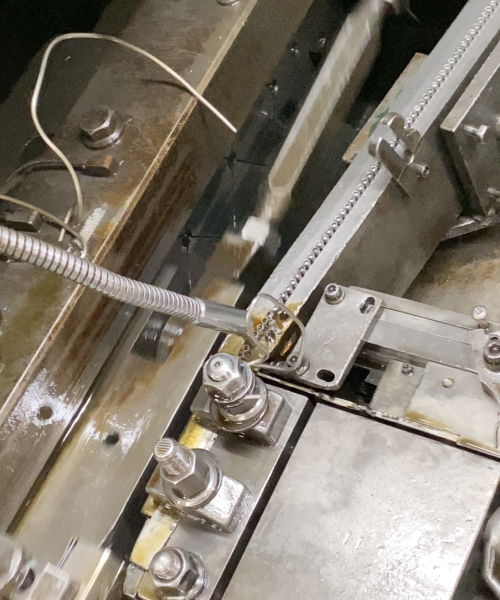

Production process

Intelligent optimization process, precision intelligent manufacturing each fastener

Custom Pricing

Sample free verification, maximum 15% refund after mass production, screw product price commitment signed online

Stage | Unit Price | Lead Time | Exclusive rights and interests |

Samples (1-10) | $ XX.XX | 3 days | Free of mould fee |

Small Batch (1000) | $ XX.XX | 7 days | Send the Destructive testing |

Mass production (100,000 +) | $ XX.XX | 15 days | General factory acceptance in factory |

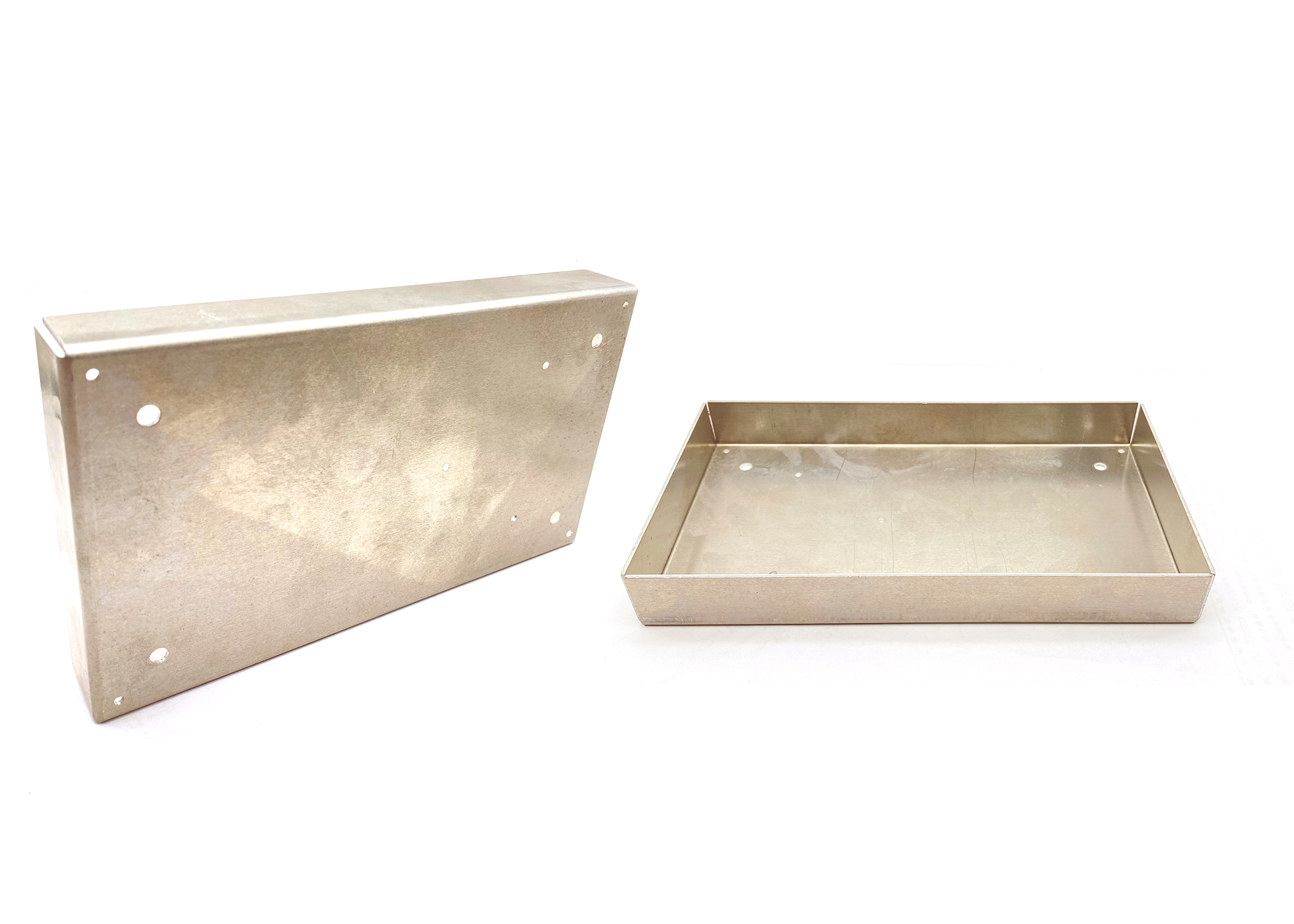

Military Products

Build Your Custom Solution in 3 Steps

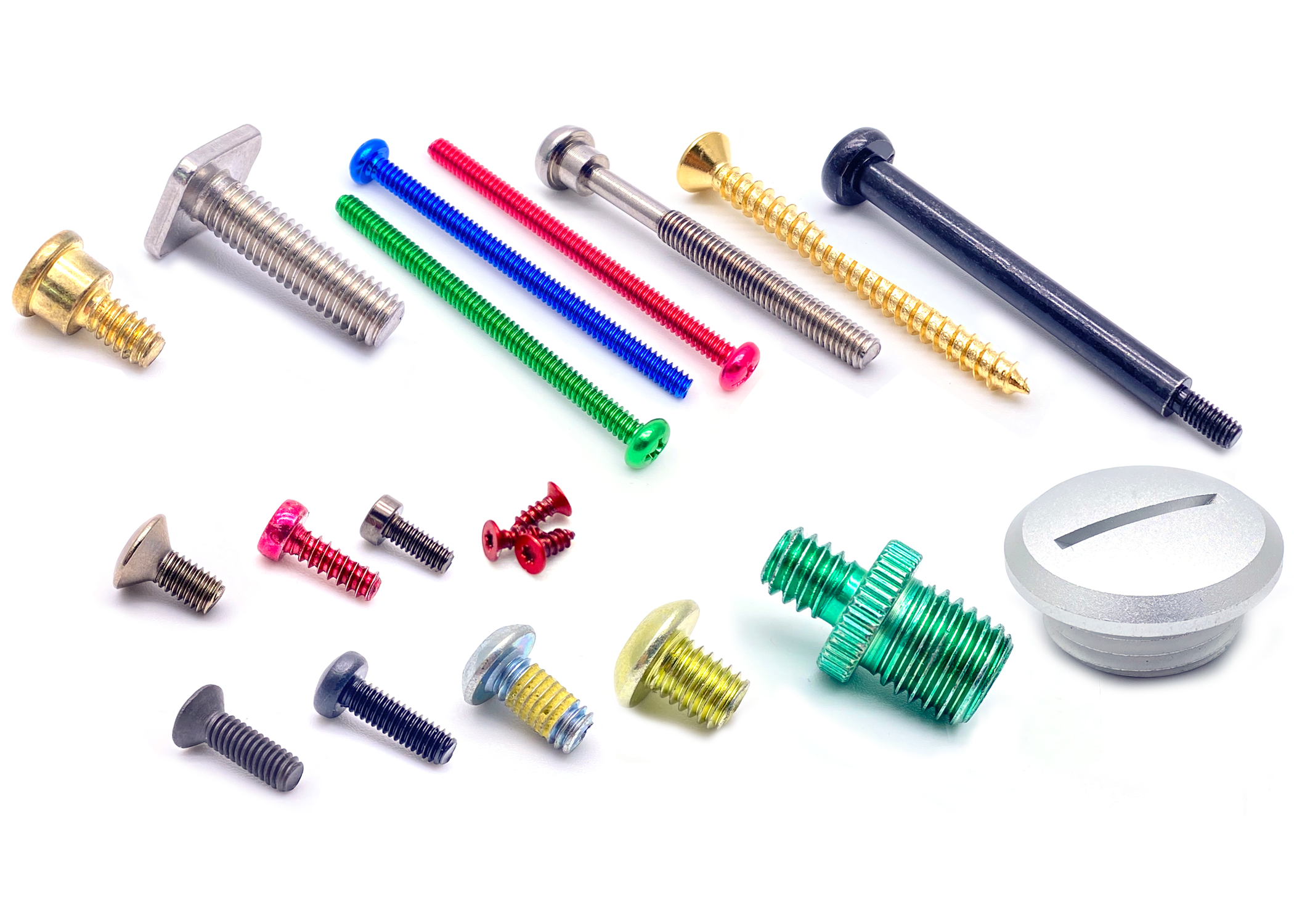

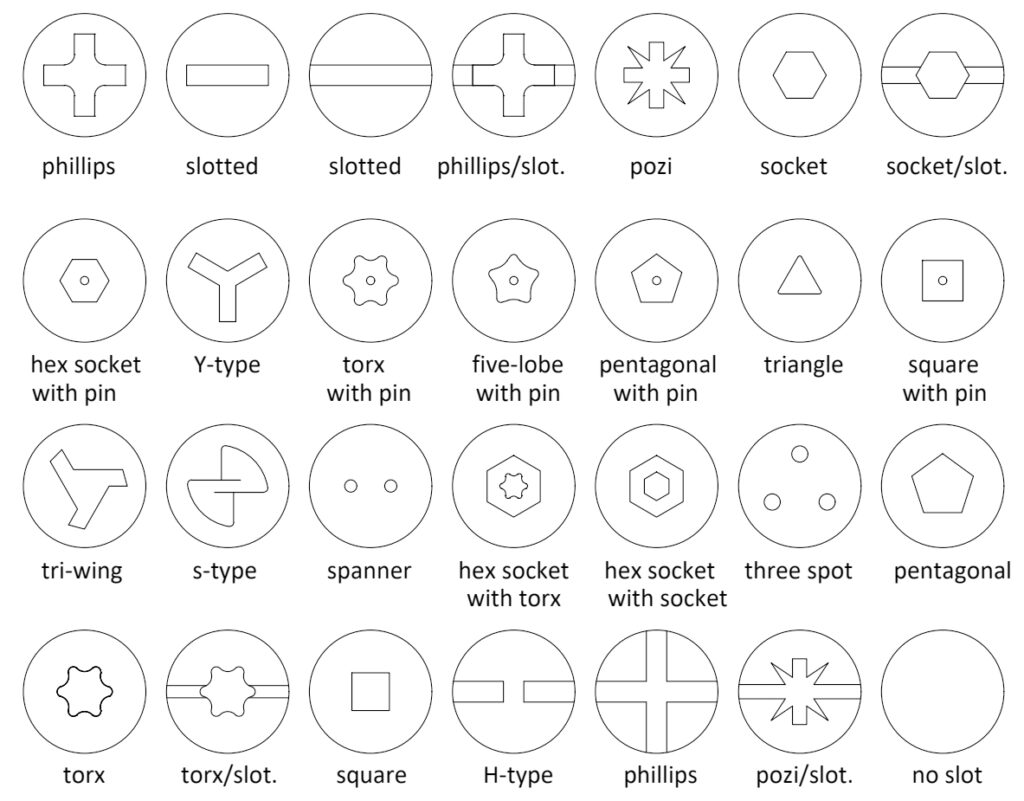

1. Select Your Groove Type – Optimize for Strength or Flexibility

Choose from 10+ engineered groove profiles – from standard V-grooves for general applications to specialized T-slots for heavy machinery.

Our CNC machining ensures ±0.005mm tolerance for perfect load distribution.

Pro Tip: 90% of industrial clients select helical grooves for vibration resistance.

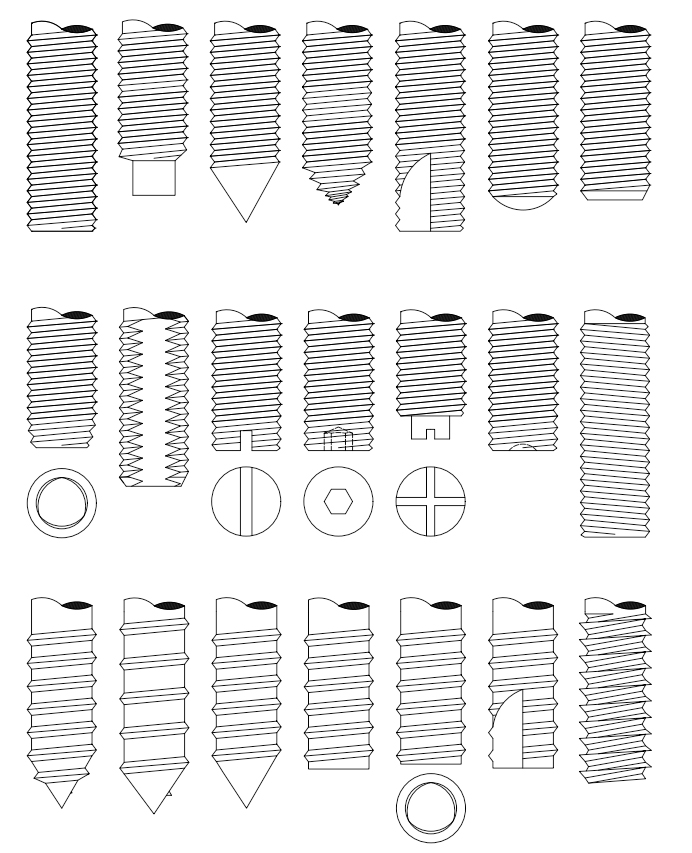

2. Choose Tooth Type: Precision Cutting or Smooth Engagement

Select triangular teeth for high-speed cutting (ideal for aerospace alloys)or rounded teeth to reduce wear in repetitive assembly (common in automotive).

Custom tooth pitch options available – Our engineers recommend 2.5mm pitch for 80% of polymer applications.

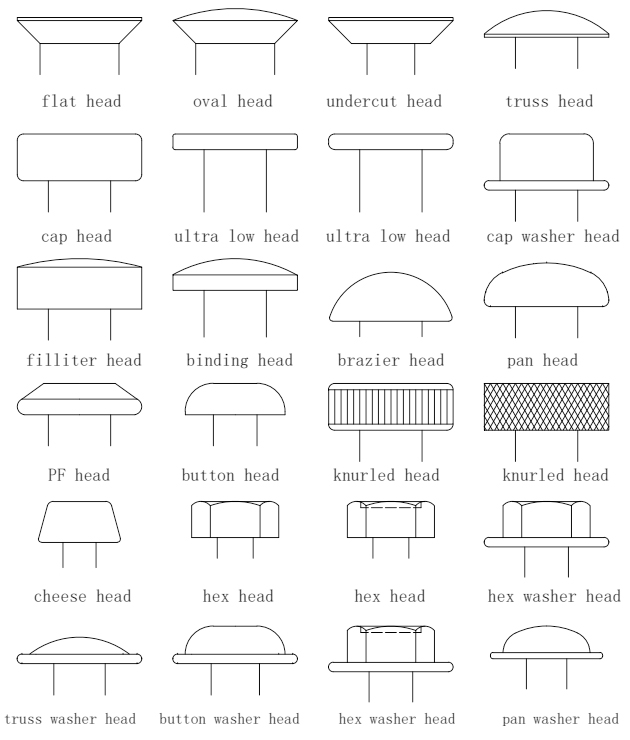

3. Design Your Head Shape: Functional Aesthetics Meets Installation Efficiency

From low-profile hex heads (ISO 4762) to tamper-resistant Torx designs, select shapes that align with your tooling ecosystem.

Pro Tip: 70% of clients pairing button heads with recessed grooves reduce installation time by 40%.

Precision-engineered from concept to delivery: Streamlined 5-stage process with 1-hour response, 72h prototyping, and ISO-certified quality control.

1.Upload Drawing

Submit CAD/PDF drawings or send samples online.

2. Your request

Shape, material, surface finish, quantity, size。

3. Rapid Prototyping

CNC precision machining + 3D printing synchronous start-up, 72 hours to deliver functional samples。

4. Provide a report

To provide you with a customized product inspection report and production cost forecast.

5. Mass Production & QC

The whole process of digital production, every 500 pieces of full inspection once, support SGS third-party inspection, 7-15 days to complete order delivery.