New Energy Battery Module Project

Secure & Reliable Fastening Solutions for New Energy Battery Packs. SST offers specialized screws, busbar hardware & insulating components engineered for lithium-ion battery module assembly, ensuring safety & performance.

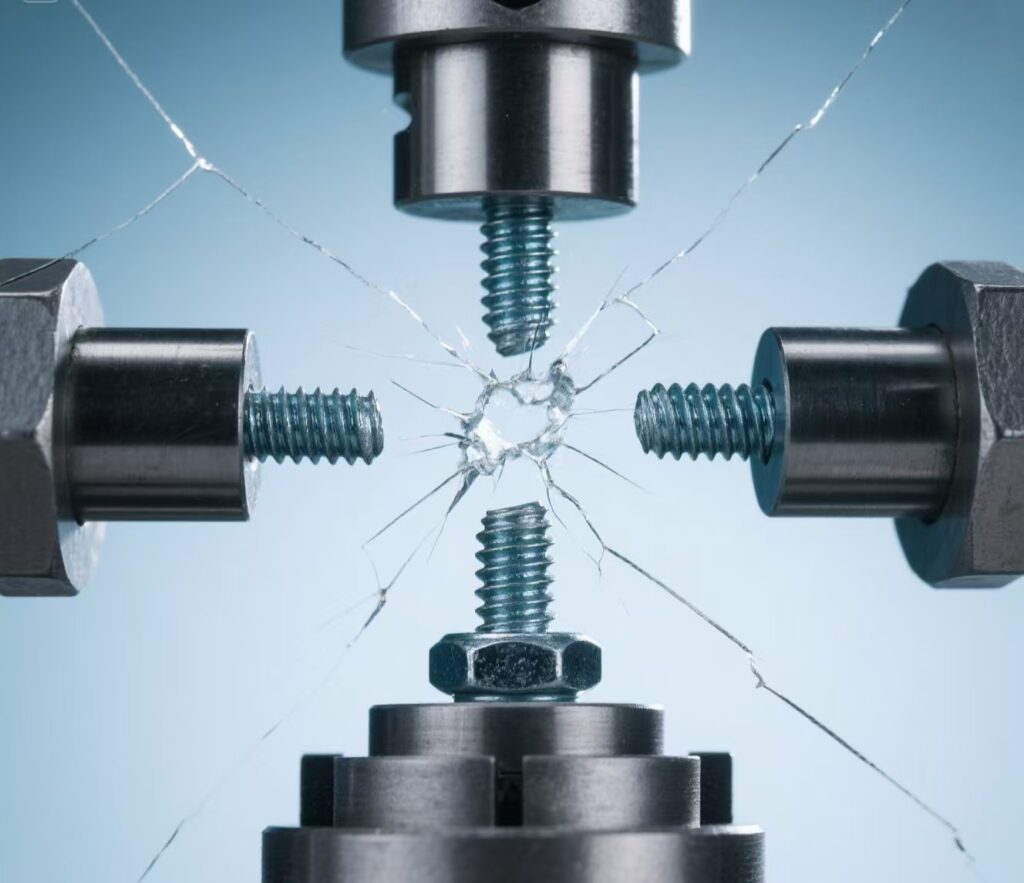

Simulated battery pack life cycle corrosive environment beyond IEC 62133

36 years general work team check, 100% simulation of actual combat environment, from the source to eliminate the risk of broken head/sliding teeth.

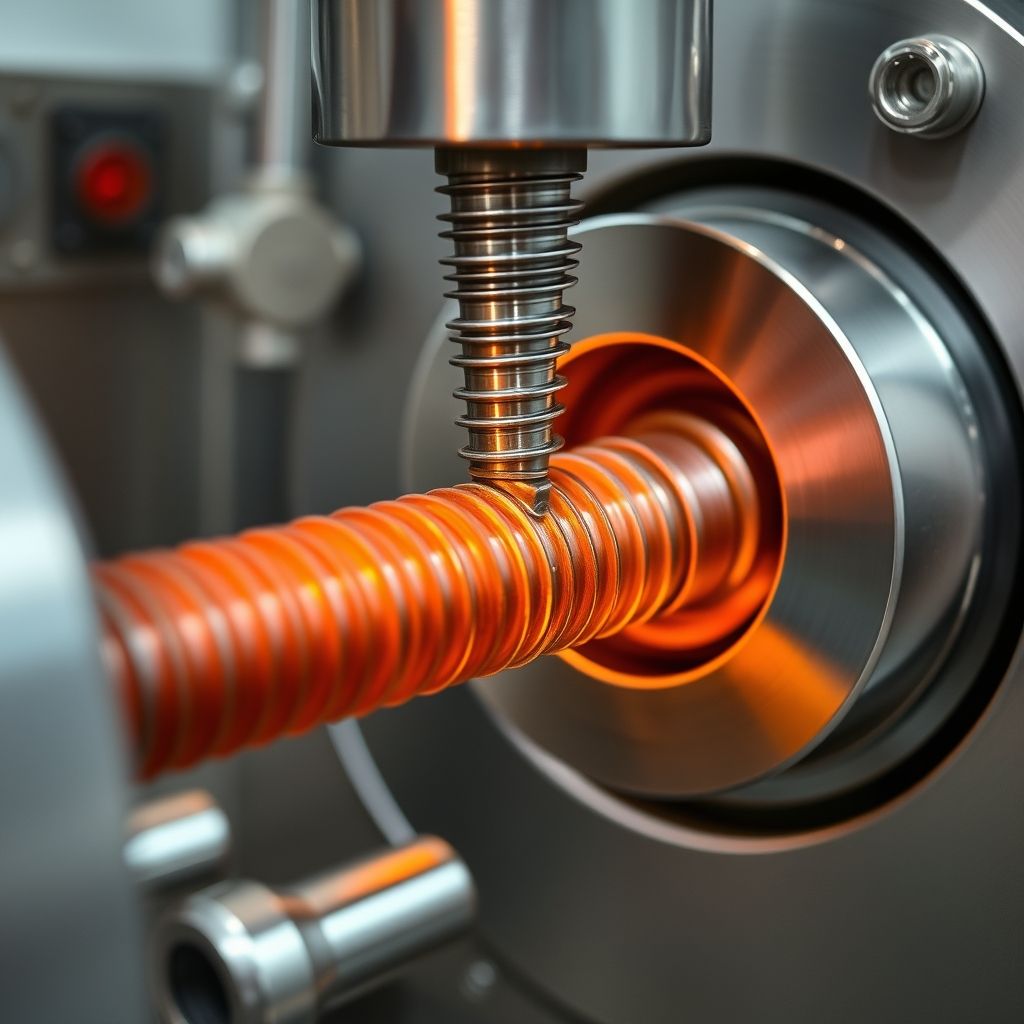

800V high voltage platform screw insulation revolution

Ceramic coating + alumina composite process, breakdown voltage > 3000V, the cost is only PEEK material 1/3

High Voltage System technology

🔹Anti-arc design:hread angle smooth processing (patent no. ZL2023XXXXXX)

🔹Intelligent warning:built-in RFID temperature sensor screw (optional)

🔹Quick Replacement: Uniform Interface Design, maintenance time reduced by 60%

Power Battery know-how

✅Anti-electrolyte corrosion: dacromet coating + sealing ring dual protection

✅Anti-seismic structure design: Step Screw + pre-coating anti-loosening process

✅Rapid heat conduction scheme: thermal conductivity of copper-aluminum composite screws > 200W/m · K

Texture | Specific strength | Electrical conductivity | Cost comparison |

7075 aluminium alloy | ★★★★☆ | ★★★☆☆ | -35% |

TC4 titanium alloy | ★★★★★ | ★★☆☆☆ | +40% |

Green manufacturing with every screw traceable

100% green electricity production, the whole process of carbon footprint tracking, to meet the EU CBAM requirements

Green Smart Manufacturing Standard

✅Photovoltaic power supply accounted for 62%

✅The recycling rate of waste water is 98%

✅Packaging material is 100% degradable

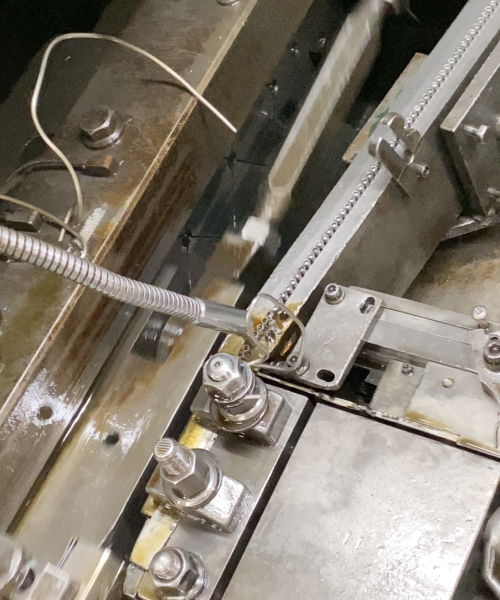

Strict Quality Control

36 years general work team check, 100% simulation of actual combat environment, from the source to eliminate the risk of broken head/sliding teeth.

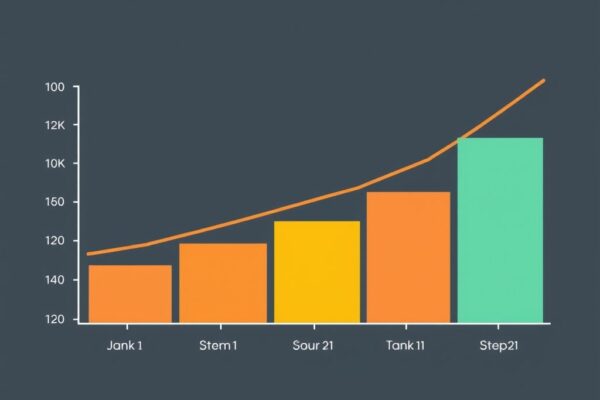

From experimental prototypes to GWh-class production, the price ladder plummets

Sample delivery in 48 hours, 15% rebate for volume orders, support for VMI inventory escrow

New Energy Price Commitment

🔹1.YEAR reduction agreement: 8% unit price reduction for every 50% increase in annual purchasing volume

🔹2. mold sharing: the same platform model sharing mold 0 cost

🔹3. Old Recycling: retired battery pack screw dismantling service free of charge

Custom Pricing

Free sample verification, maximum 15% refund after mass production, product price commitment signed online

Stage | Unit Price | Lead Time | Exclusive rights and interests |

Samples (1-10) | $ XX.XX | 3 days | Free of mould fee |

Small Batch (1000) | $ XX.XX | 7 days | Send the Destructive testing |

Mass production (100,000 +) | $ XX.XX | 15 days | General factory acceptance in factory |

Crisis response faster than battery self-ignition

Quality Problems 2 hours to lock the root cause, emergency shortage 4 hours inter-warehouse allocation

Types of questions | Response time | Solution criteria |

The accident of stopping the line | 30 minutes | Priority Replenishment by air freight |

Bad Batch | 2 hours | Full replacement + compensation |

Process optimization | 24 hours | Engineer on-site solution |

Power Battery exclusive protection

✅Regional Safety Stock:set up emergency warehouse in Yangtze River Delta and Pearl River Delta

✅Interest-free period support:90-day period for strategic customers

✅Technical co-construction program: free DFM design training

New Energy Testing System

UL1642/IEC 62619 Battery safety certification with support for UN38.3 transport testing

01.

Raw material RoHS + REACH test

Strictly Control 25 kinds of harmful substances, double certification escort global market access

02.

Process X-ray inspection

There is no place to hide the micron-level defects, and the detection accuracy reaches the ASTM E1444 standard

03.

Insulation resistance test of finished product > 100 m ω

500V Megohm meter check, insulation barrier withstand 3000V high voltage impact

Production Process

Intelligent optimization process, precision intelligent manufacturing each fastener

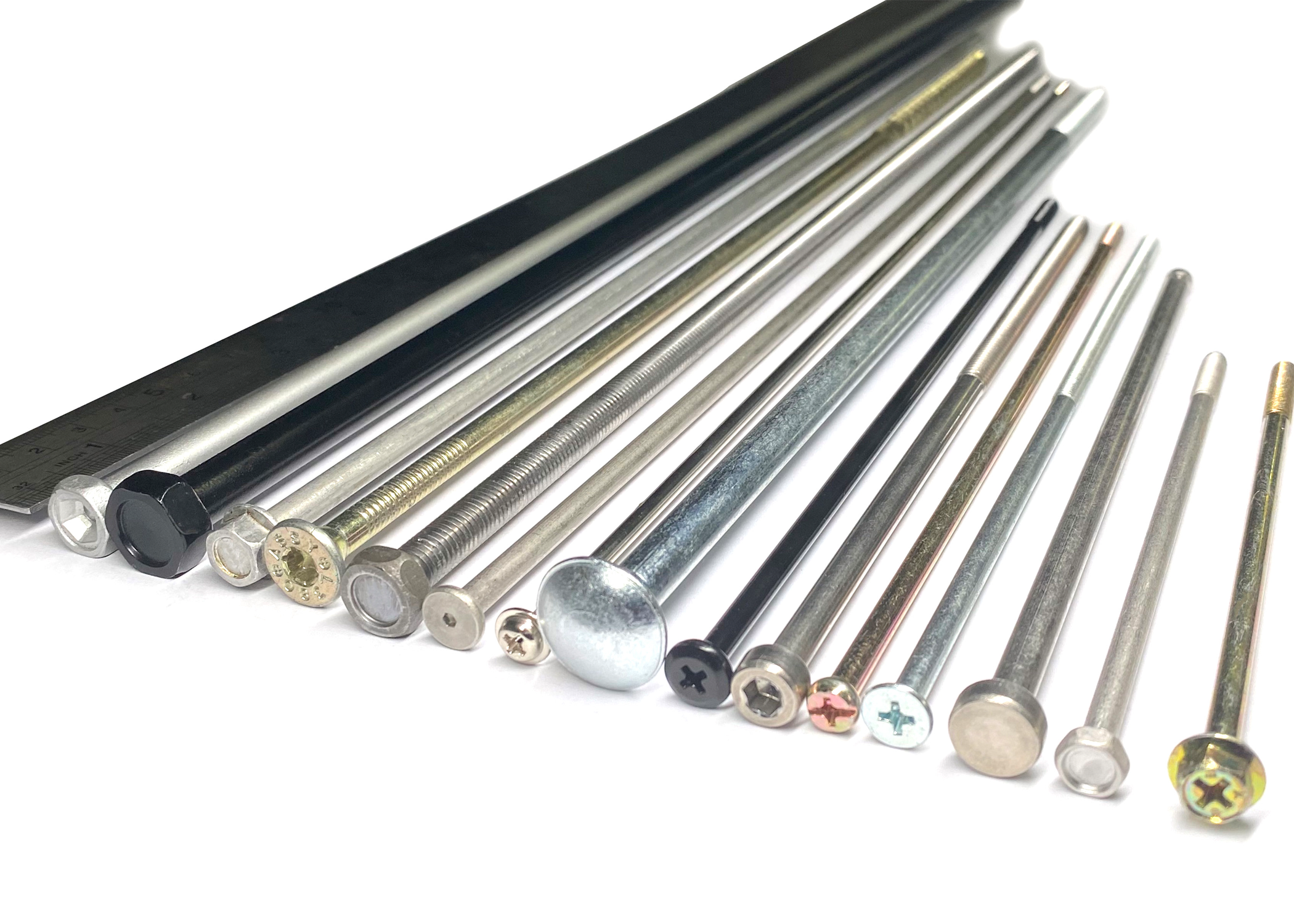

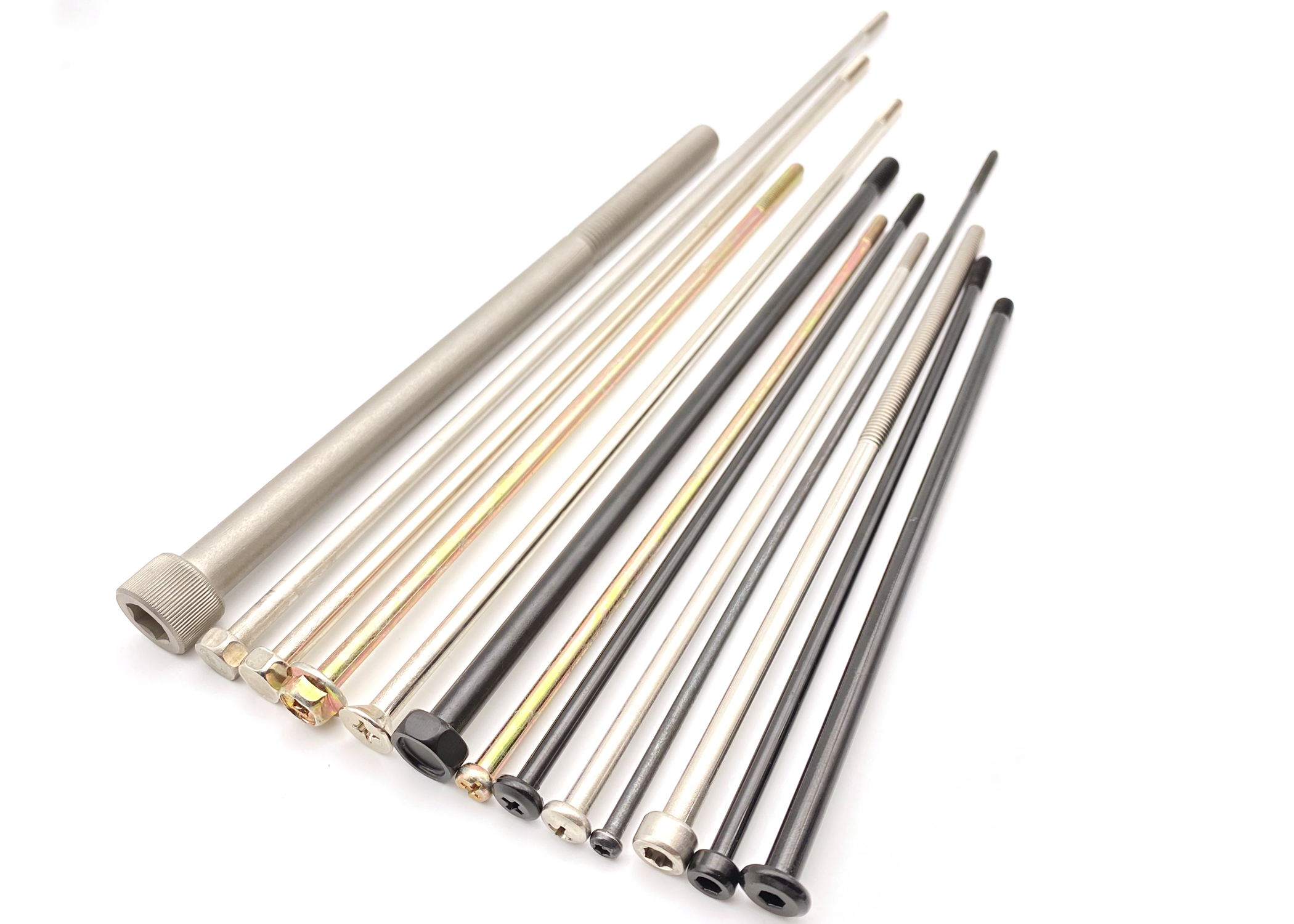

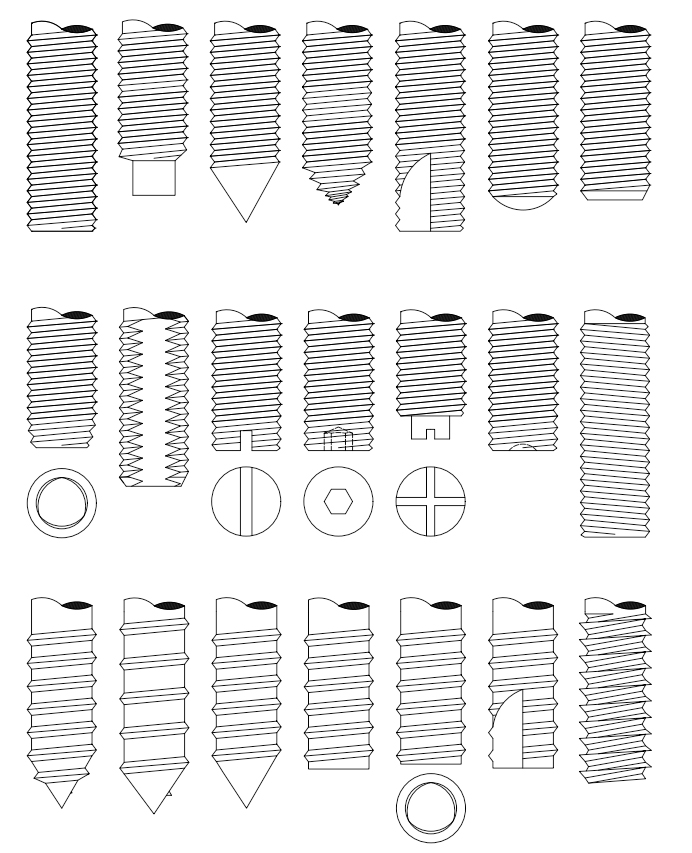

Products

Build Your Custom Solution in 3 Steps

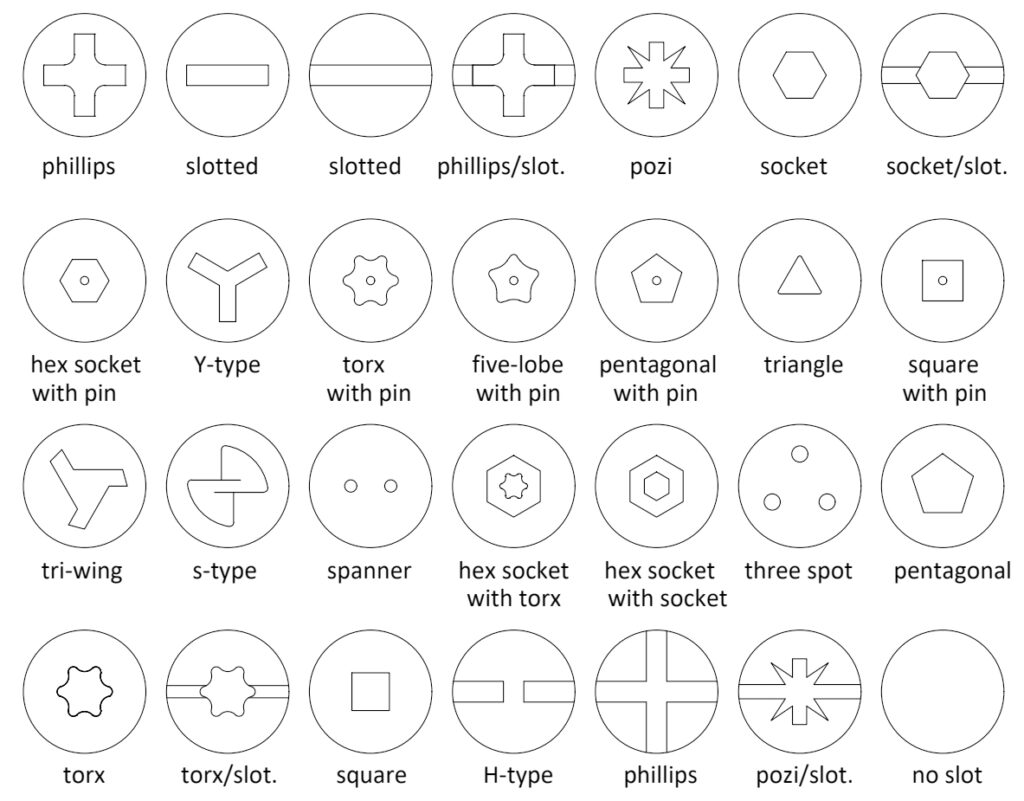

1. Select Your Groove Type – Optimize for Strength or Flexibility

Choose from 10+ engineered groove profiles – from standard V-grooves for general applications to specialized T-slots for heavy machinery.

Our CNC machining ensures ±0.005mm tolerance for perfect load distribution.

Pro Tip: 90% of industrial clients select helical grooves for vibration resistance.

2. Choose Tooth Type: Precision Cutting or Smooth Engagement

Select triangular teeth for high-speed cutting (ideal for aerospace alloys)or rounded teeth to reduce wear in repetitive assembly (common in automotive).

Custom tooth pitch options available – Our engineers recommend 2.5mm pitch for 80% of polymer applications.

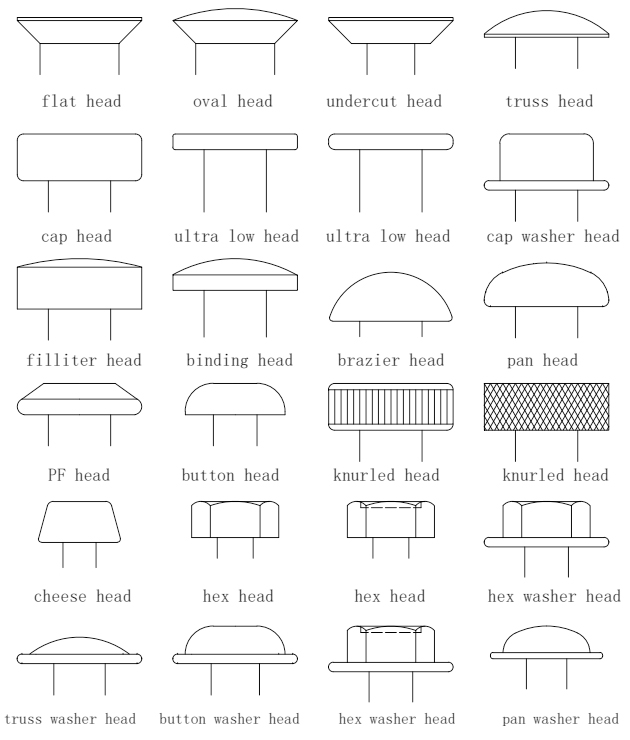

3. Design Your Head Shape: Functional Aesthetics Meets Installation Efficiency

From low-profile hex heads (ISO 4762) to tamper-resistant Torx designs, select shapes that align with your tooling ecosystem.

Pro Tip: 70% of clients pairing button heads with recessed grooves reduce installation time by 40%.

Precision-engineered from concept to delivery: Streamlined 5-stage process with 1-hour response, 72h prototyping, and ISO-certified quality control.

1.Upload Drawing

Submit CAD/PDF drawings or send samples online.

2. Your request

Shape, material, surface finish, quantity, size。

3. Rapid Prototyping

CNC precision machining + 3D printing synchronous start-up, 72 hours to deliver functional samples。

4. Provide a report

To provide you with a customized product inspection report and production cost forecast.

5. Mass Production & QC

The whole process of digital production, every 500 pieces of full inspection once, support SGS third-party inspection, 7-15 days to complete order delivery.