Oil Pipelines

Corrosion-Resistant Fastening Solutions for Oil & Gas Pipelines. Find high-integrity bolts, nuts, washers & flanges with superior coatings (Xylan, Dacromet) designed for extreme corrosion resistance in pipeline construction & maintenance.

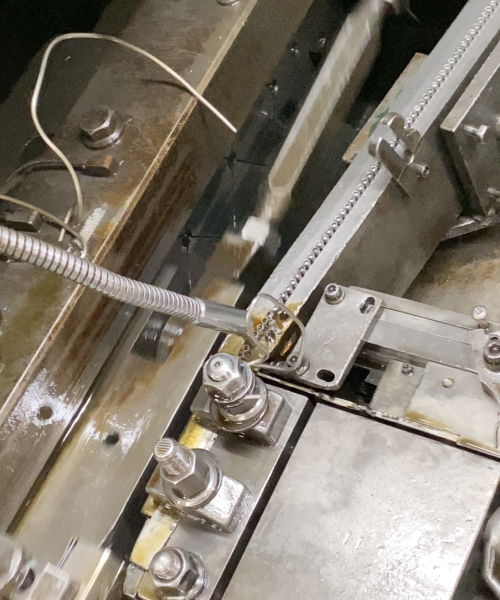

Hydrogen sulfide corrosion resistant screw system

X65 Steel/duplex stainless steel special material, H2S partial pressure > 0.3 psi, salt spray test for more than 5000 hours

Oil and gas know-how matrix

🔹Common materials: 431,660,316L, A286

🔹Stress Corrosion Protection: QPQ + zn-ni alloy composite coating

🔹Seismic design: flange serrated locking structure (patent no. ZL2023XXXXXX)

🔹Quick Install: Design of a unified API standard interface

Texture | Yield | Grade of resistance to sulphur | Cost comparison |

X65 Steel | 450MPa | NACE B Grade | -20% |

2205 dual phase steel | 620MPa | NACE A Grade | +35% |

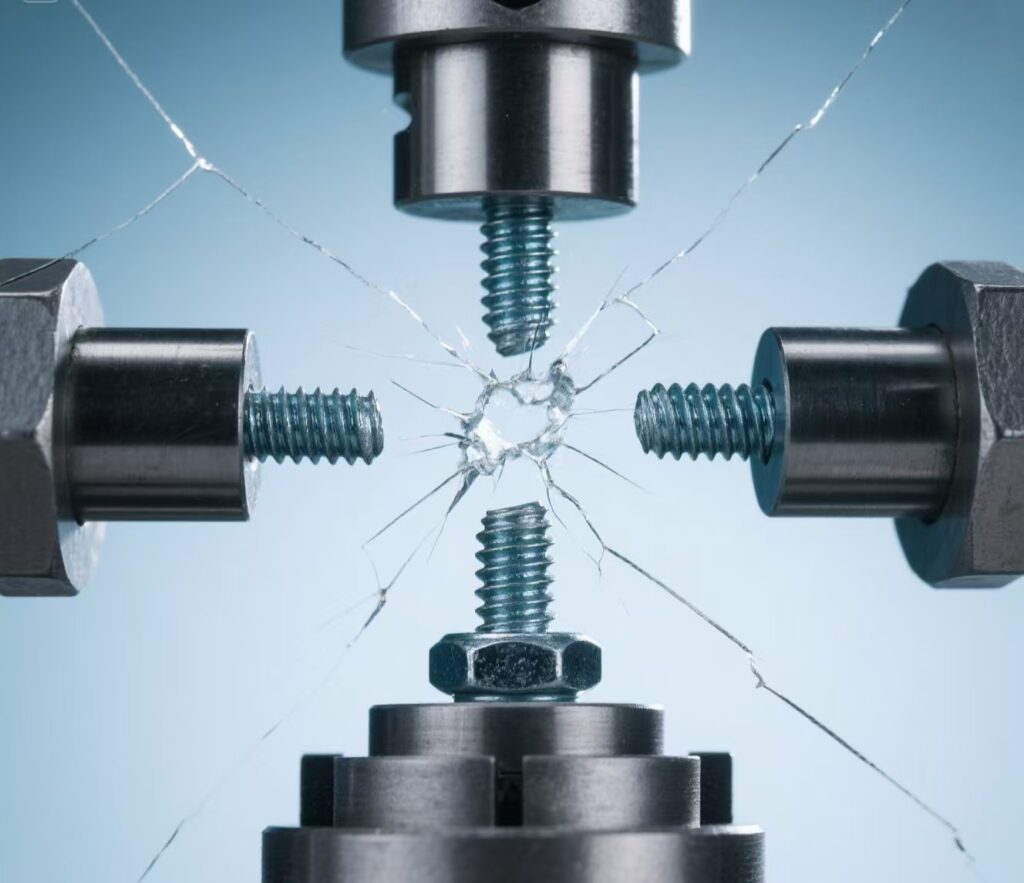

Every bolt will stand the test of the pole

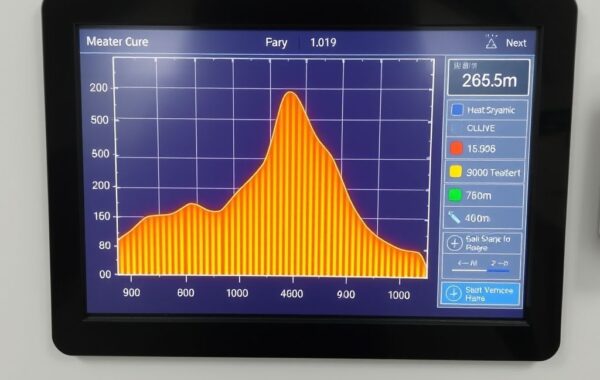

Impact test line at -50 °C + high temperature hydrogen sulfide simulation chamber, accuracy exceeding ASME B16.5 standard

Standard for intelligent production of oil and gas

✅-50 °C Impact Energy > 100J

✅The sensitivity of hydrogen embrittlement is less than 15%

✅Coating adhesion > 20 mpa

* support PSL2/PSL3 pipe fittings of different grades *

Strict Quality Control

36 years general work team check, 100% simulation of actual combat environment, from the source to eliminate the risk of broken head/sliding teeth.

Data Detection

We will carry out a lot of screw products sampling test, to ensure that customers get our qualified products.

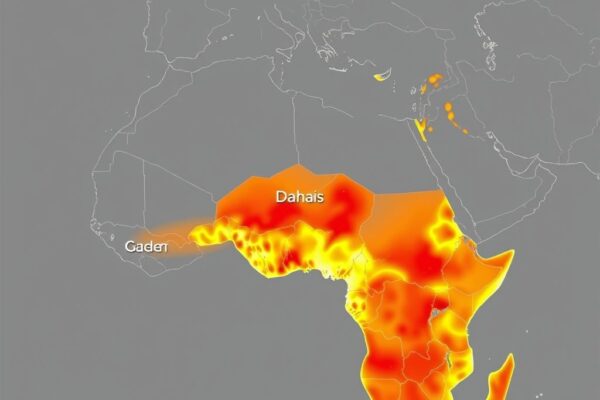

A faster global response than an oil spill

72-hour global arrival, with 128 strategic storage sites covering major oil production

Exclusive rights and interests in oil and gas

🔹Free software for calculating pre-tightening force of pipe bolts

🔹Strategic customers enjoy annual inspection of anti-corrosion coatings

🔹Recycling, smelting and regenerating service of old parts

Emergency level | Response time | The solution |

Level 1(pipe burst) | 24 hours | Special plane direct delivery + on-site rush repair |

Level 2(leakage) | 48 hours | Direct land transportation to the nearest reservoir point |

Level 3(warning) | 72 hours | On-demand replenishment in JIT mode |

Why did CNPC choose our 10000 psi burst test?

Full-scale pipeline simulation test device, 1:1 reproduction of the west-east gas transmission conditions

Process breakthrough in cost reduction of pipe flange bolt by 55%

Hot forging instead of machining, Dacromet coating instead of hard chromium plating, life increased by 3 times

Parameters | Traditional machining | Hot forging process |

Cost | ¥46/piece | ¥21/piece |

Production rate | 25 pieces per hour | 150 pieces per hour |

Fatigue life | A hundred thousand times | Three hundred thousand |

The secret of oil and gas optimization

🔹Anti-fretting wear: shot peening of Thread

🔹Quick Response: Mold preheat system, changeover time < 30 minutes

🔹Intelligent early warning: BOLT preload wireless monitoring system (optional)

From the prototype to the 1,000 km level, the price ladder drops by 70%

Sample 72-hour delivery, strategic customers enjoy engineering and technical personnel on-site services

Oil and gas procurement commitment

🔹15-year extended warranty

🔹provide operation and maintenance cost insurance by mileage

🔹old for new

DNV GL certification, serving 17 oil and gas projects worldwide

01.

Material cost accounted for 51%

02.

Anticorrosion process 23%

03.

Testing cost 13%

04.

Profit 13%

Custom Pricing

Free sample verification, maximum 15% refund after mass production, product price commitment signed online

Stage | Unit Price | Lead Time | Exclusive rights and interests |

Samples (1-10) | $ XX.XX | 3 days | Free of mould fee |

Small Batch (1000) | $ XX.XX | 7 days | Send the Destructive testing |

Mass production (100,000 +) | $ XX.XX | 15 days | General factory acceptance in factory |

Oil and gas procurement commitment

DNV GL certification, serving 17 oil and gas projects worldwide.

01.

Sulfide stress corrosion testing (SSC) of raw materials

Sulfide stress corrosion testing, NACE TM0177 standard zero failure.

02.

Penetrant inspection of Welds

0.1 mm crack is nowhere to be found by precise fluorescent penetrant inspection.

03.

Hydrogen induced cracking test of finished products (HIC)

100% qualified rate of hydrogen induced cracking test, ISO 15156 international certification

Production Process

Intelligent optimization process, precision intelligent manufacturing each fastener

Products

Build Your Custom Solution in 3 Steps

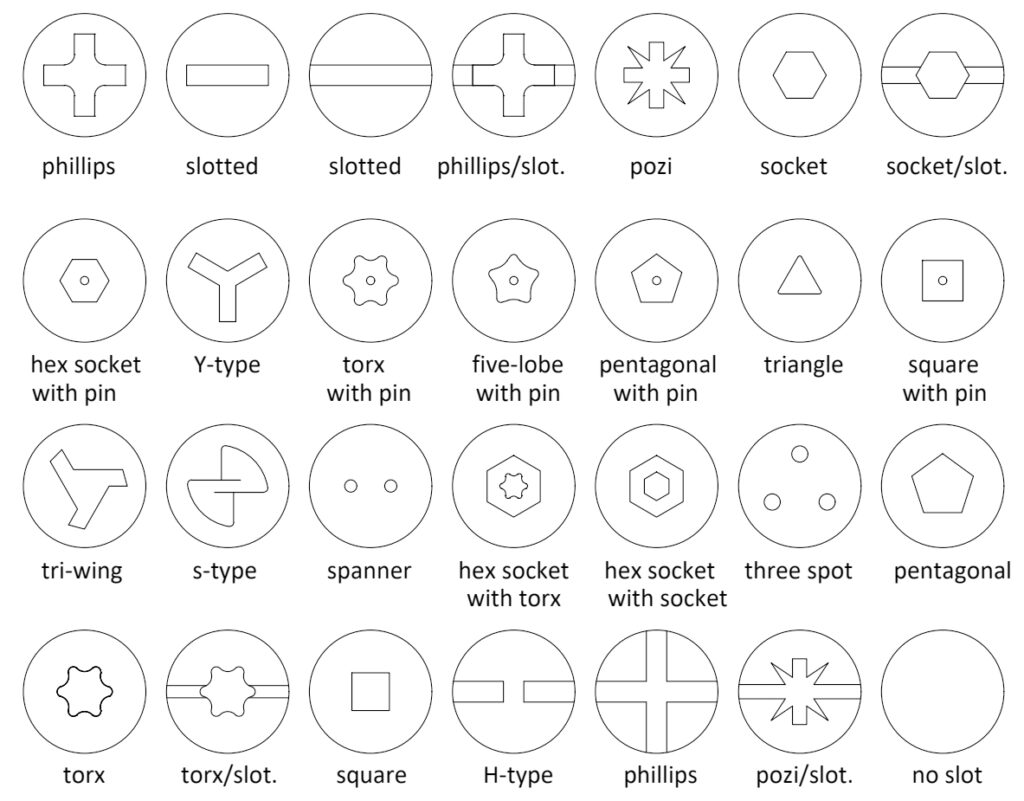

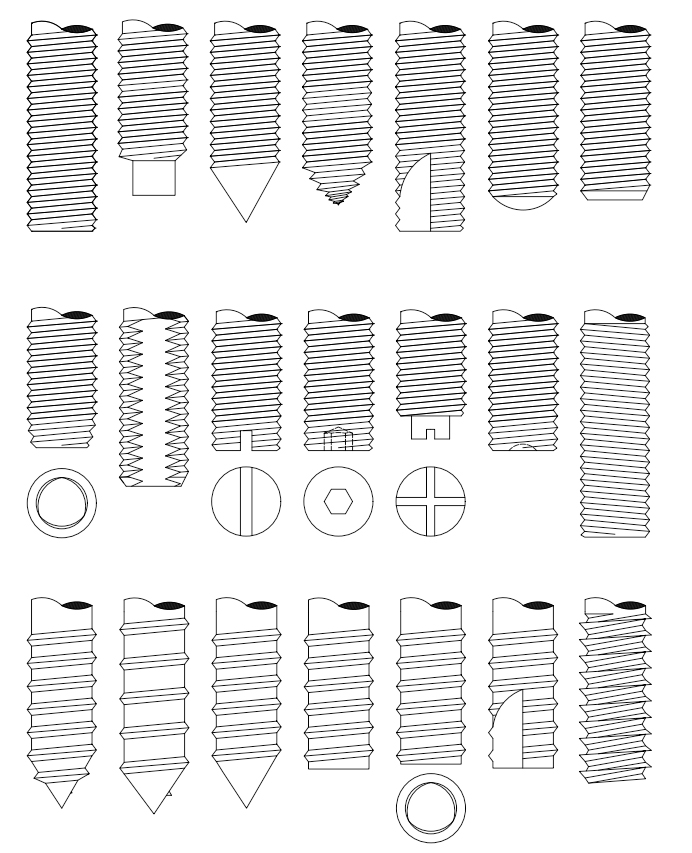

1. Select Your Groove Type – Optimize for Strength or Flexibility

Choose from 10+ engineered groove profiles – from standard V-grooves for general applications to specialized T-slots for heavy machinery.

Our CNC machining ensures ±0.005mm tolerance for perfect load distribution.

Pro Tip: 90% of industrial clients select helical grooves for vibration resistance.

2. Choose Tooth Type: Precision Cutting or Smooth Engagement

Select triangular teeth for high-speed cutting (ideal for aerospace alloys)or rounded teeth to reduce wear in repetitive assembly (common in automotive).

Custom tooth pitch options available – Our engineers recommend 2.5mm pitch for 80% of polymer applications.

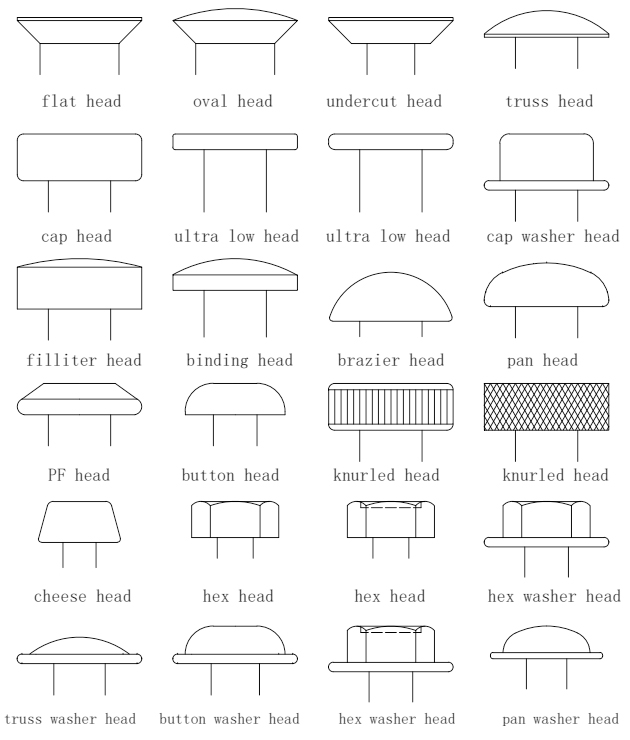

3. Design Your Head Shape: Functional Aesthetics Meets Installation Efficiency

From low-profile hex heads (ISO 4762) to tamper-resistant Torx designs, select shapes that align with your tooling ecosystem.

Pro Tip: 70% of clients pairing button heads with recessed grooves reduce installation time by 40%.

Precision-engineered from concept to delivery: Streamlined 5-stage process with 1-hour response, 72h prototyping, and ISO-certified quality control.

1.Upload Drawing

Submit CAD/PDF drawings or send samples online.

2. Your request

Shape, material, surface finish, quantity, size。

3. Rapid Prototyping

CNC precision machining + 3D printing synchronous start-up, 72 hours to deliver functional samples。

4. Provide a report

To provide you with a customized product inspection report and production cost forecast.

5. Mass Production & QC

The whole process of digital production, every 500 pieces of full inspection once, support SGS third-party inspection, 7-15 days to complete order delivery.