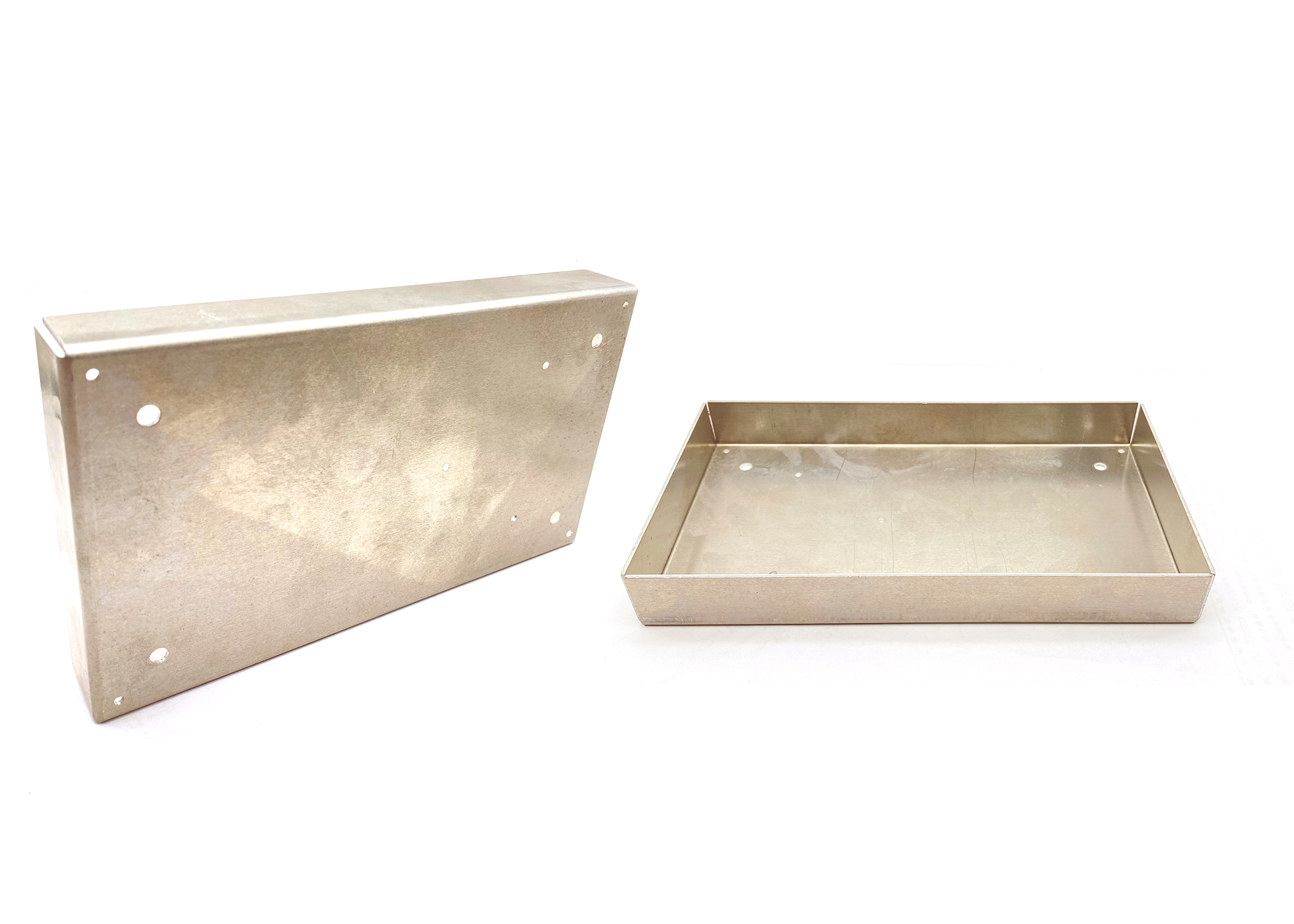

Smart home-optical electronics and appliances

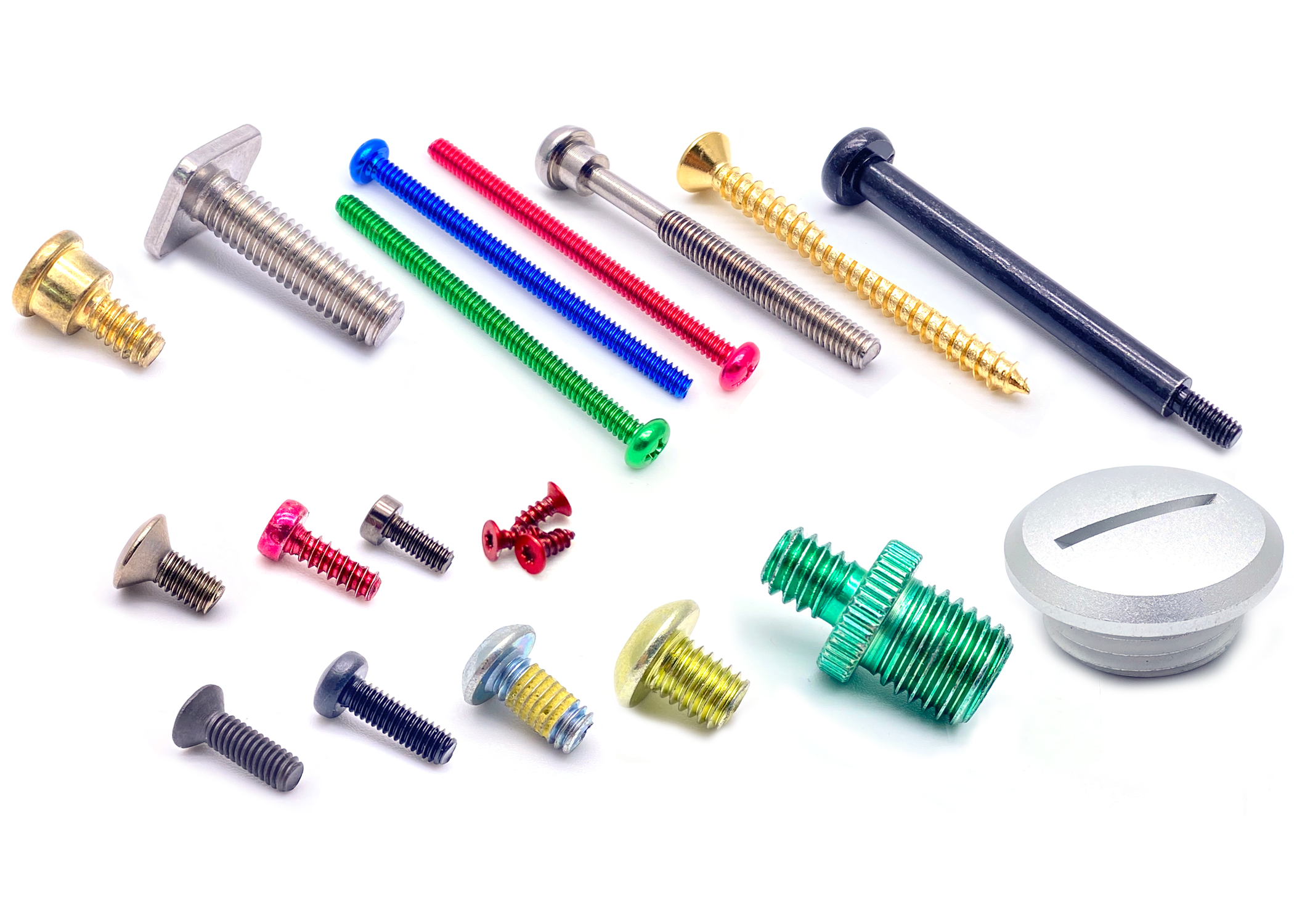

Miniature & Precision Fasteners for Smart Tech & Appliances. Source tiny screws, micro fasteners & specialized electronic hardware for sensitive optical devices, smart home systems, consumer electronics & appliance assembly.

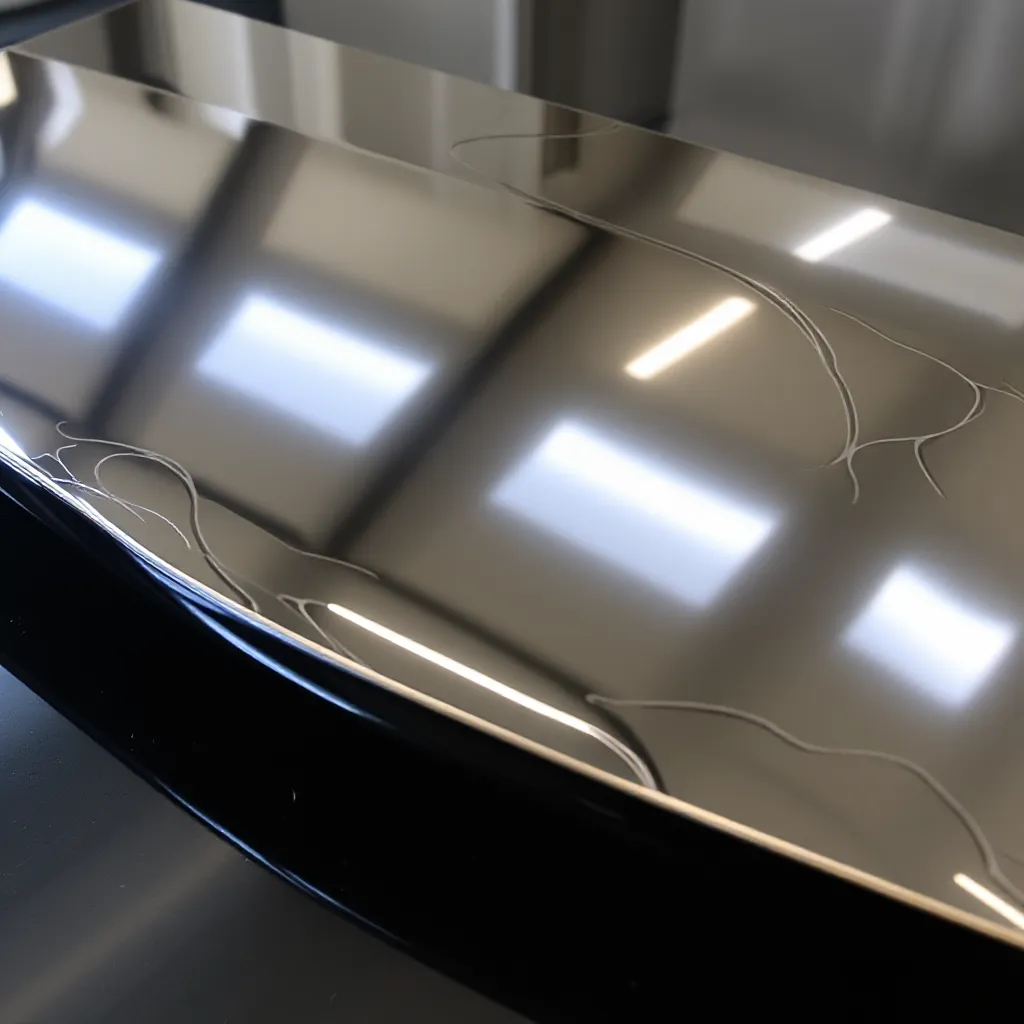

Why does the optics industry have to be ± 0.005 mm accurate?

Thousands of clean workshop production, eliminate the lens bracket screw dust pollution risk

Connector screws plummet in cost by 40% with the conductive revolution

Using beryllium copper instead of gold-plated steel parts, the cost is reduced by 1/2 and the life is increased by 3 times with the same conductivity

Know-how in electronics and electricity:

🔹Galvanic corrosion protection:isolation coating technology for dissimilar metals

🔹High frequency optimization:microwave reflectivity < 0.3 db for threaded corner

🔹Quick changeover: < 15 minutes for mold changeover time

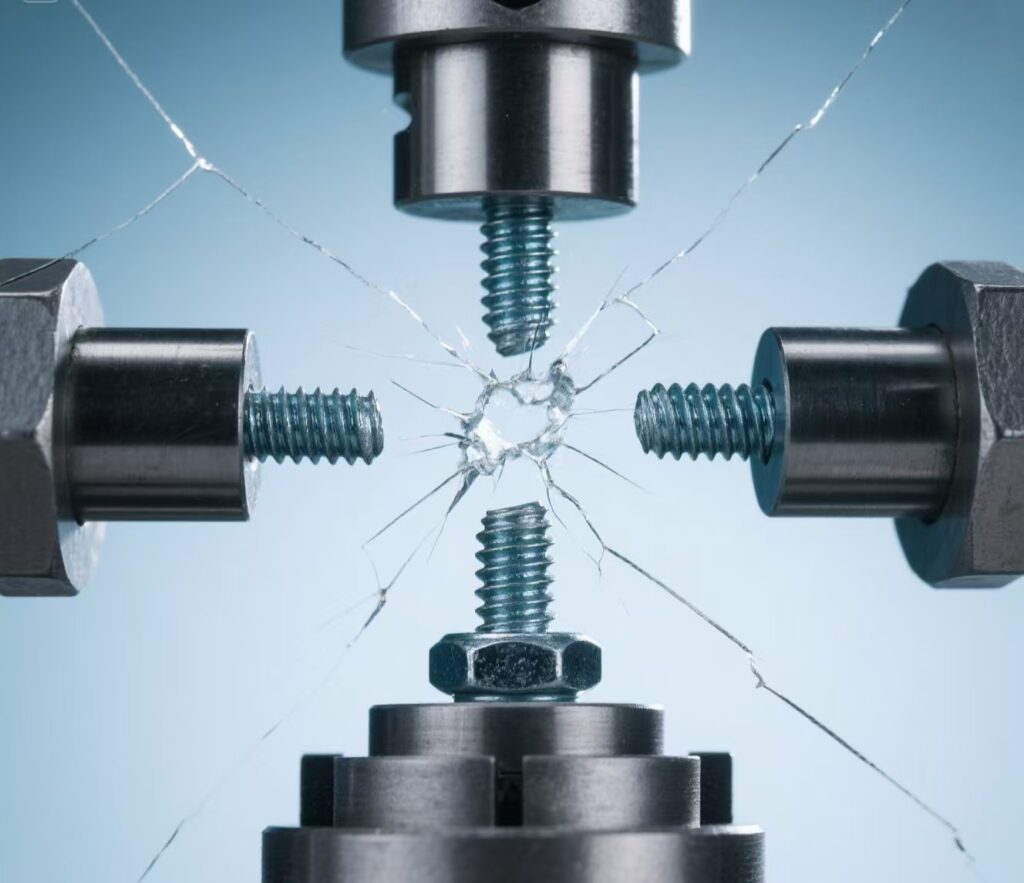

Strict Quality Control

36 years general work team check, 100% simulation of actual combat environment, from the source to eliminate the risk of broken head/sliding teeth.

Data Detection

We will carry out a lot of screw products sampling test, to ensure that customers get our qualified products.

Optical grade quality control system

It has been audited by the secondary suppliers of major optical factories such as Zeiss and SHUNYU

01.

vacuum packaging of raw materials

Vacuum seal isolation dust pollution, nano-level clean protection of optical raw material purity

02.

Anti-static control of the whole process

Production to the packaging of zero electrostatic interference, guard precision components without damage.

03.

Particle contamination test report for each batch

Strict control of particulate matter > 0.3 ΜM, with ISO 14644-1class 7 test data.

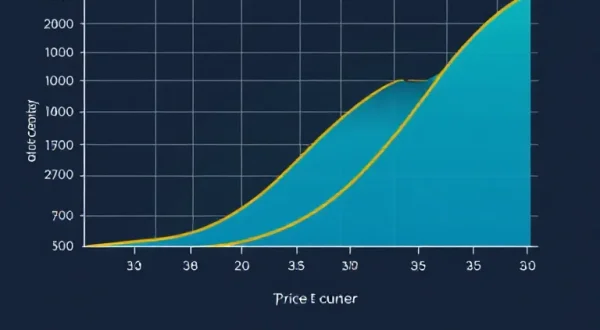

From 1 to 1m pieces, the price goes straight to no formula

The industry’s first mini-piece ladder pricing system, the greater the volume of the more surprising unit price

Three Price guarantees:

🔹1 sample free of charge (limited order)

🔹230 days price insurance

🔹3 more than 1% defective rate full refund

The 2023 saved e-customers more than $8.6 million in procurement costs

See the power of precision: 160 mind games in real time

The Swiss Tornos cluster of devices churns out 3M ultra-precision screws a day

Smart Consumer Electronics Standard:

✅micropart tolerance ± 0.01 mm

✅appearance AQL 0.65

✅salt spray test > 72h

Support VMI inventory management, JIT mode 2 hours fast replenishment

Faster problem response than chip iteration

Issue root cause report within 12 hours for quality problems, and make replenishment within 8 hours for emergency orders

Exclusive protection for the electronics industry:

🔹Anti-static packaging free of charge

🔹Support for chip-level traceability

🔹Factory-based QE services

Problem level | Response time | Commitment to resolve |

Fatal (Stop Line) | 15 minutes | 4 hours to the scene |

Serious (rejected) | 30 minutes | 8-hour exchange |

General (customer complaint) | 2 hours | 24-hour programme |

Production Process

Intelligent optimization process, precision intelligent manufacturing each fastener

Custom Pricing

Sample free verification, maximum 15% refund after mass production, screw product price commitment signed online

Stage | Unit Price | Lead Time | Exclusive rights and interests |

Samples (1-10) | $ XX.XX | 3 days | Free of mould fee |

Small Batch (1000) | $ XX.XX | 7 days | Send the Destructive testing |

Mass production (100,000 +) | $ XX.XX | 15 days | General factory acceptance in factory |

Build Your Custom Solution in 3 Steps

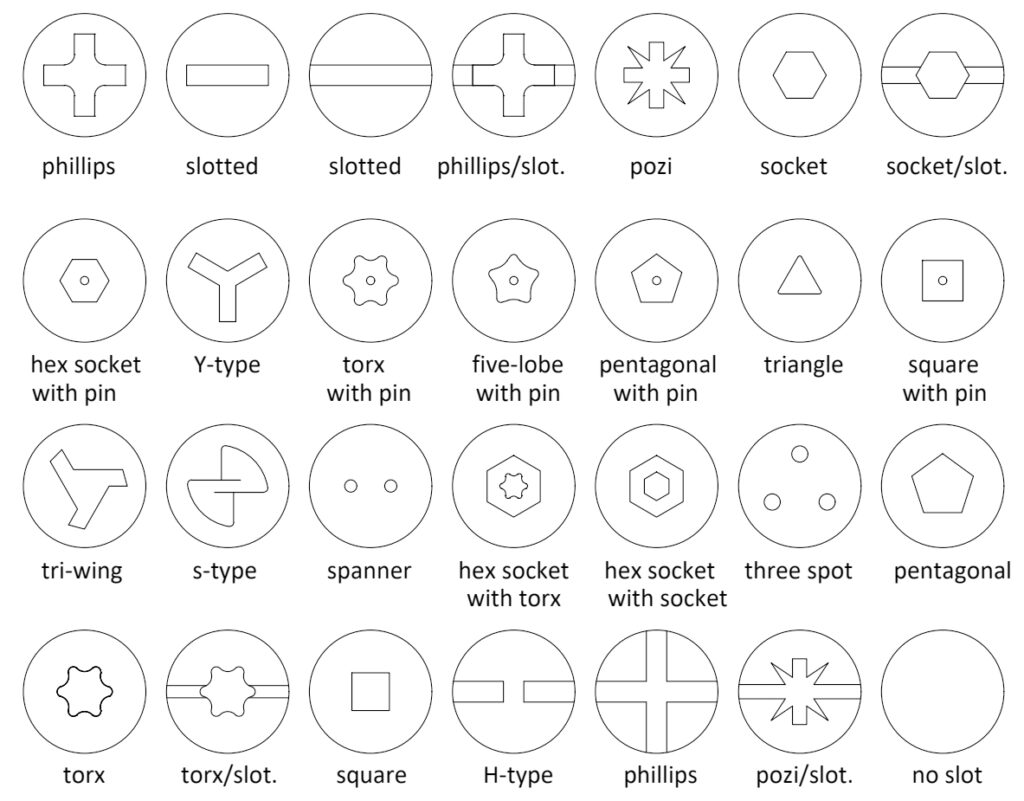

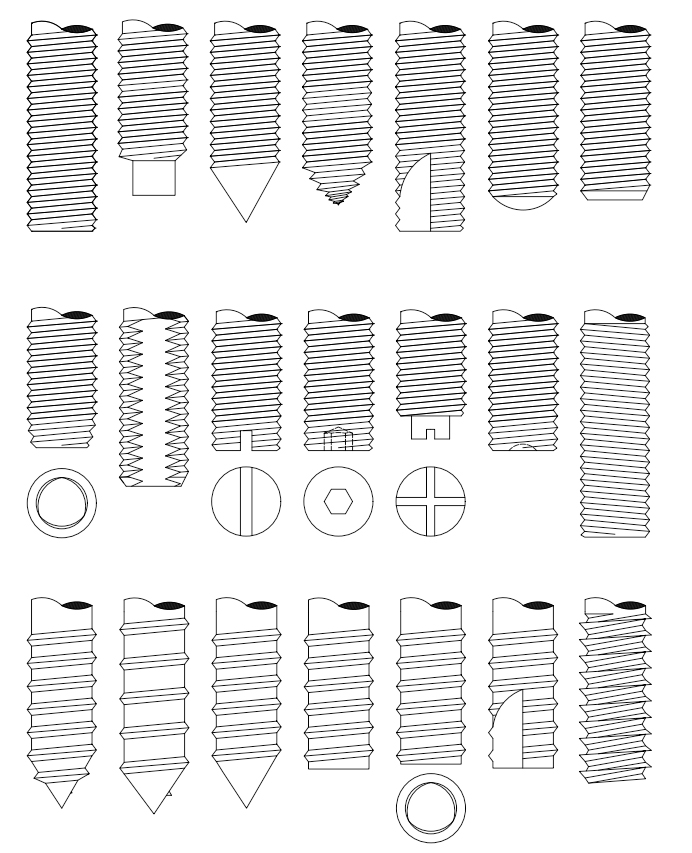

1. Select Your Groove Type – Optimize for Strength or Flexibility

Choose from 10+ engineered groove profiles – from standard V-grooves for general applications to specialized T-slots for heavy machinery.

Our CNC machining ensures ±0.005mm tolerance for perfect load distribution.

Pro Tip: 90% of industrial clients select helical grooves for vibration resistance.

2. Choose Tooth Type: Precision Cutting or Smooth Engagement

Select triangular teeth for high-speed cutting (ideal for aerospace alloys)or rounded teeth to reduce wear in repetitive assembly (common in automotive).

Custom tooth pitch options available – Our engineers recommend 2.5mm pitch for 80% of polymer applications.

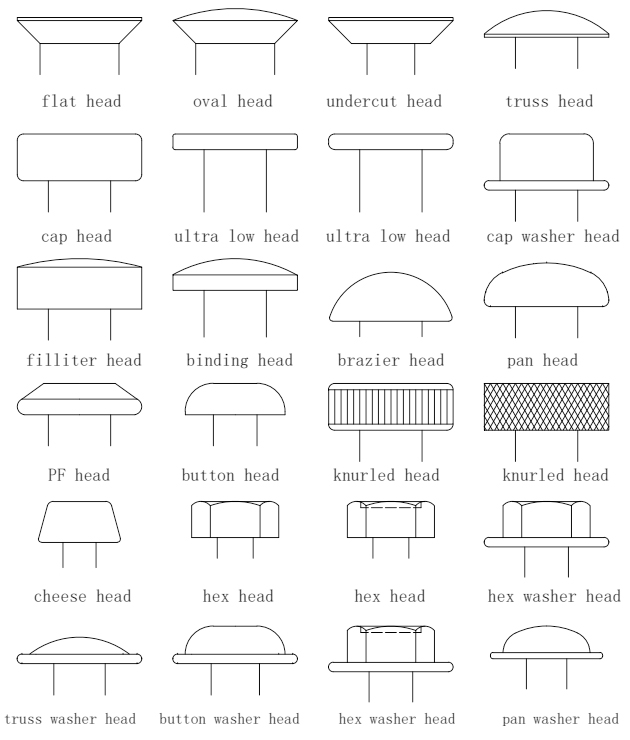

3. Design Your Head Shape: Functional Aesthetics Meets Installation Efficiency

From low-profile hex heads (ISO 4762) to tamper-resistant Torx designs, select shapes that align with your tooling ecosystem.

Pro Tip: 70% of clients pairing button heads with recessed grooves reduce installation time by 40%.

Precision-engineered from concept to delivery: Streamlined 5-stage process with 1-hour response, 72h prototyping, and ISO-certified quality control.

1.Upload Drawing

Submit CAD/PDF drawings or send samples online.

2. Your request

Shape, material, surface finish, quantity, size。

3. Rapid Prototyping

CNC precision machining + 3D printing synchronous start-up, 72 hours to deliver functional samples。

4. Provide a report

To provide you with a customized product inspection report and production cost forecast.

5. Mass Production & QC

The whole process of digital production, every 500 pieces of full inspection once, support SGS third-party inspection, 7-15 days to complete order delivery.