Spring

✅ Micro-Precision: Wire Ø0.08mm (Human Hair = Ø0.1mm) | ±2% Load Consistency

✅ Extreme Endurance: 300K~10M+ Cycles (Test Reports Available)

✅ Exotic Materials: SUS631/SupremAlloy®/NiTi Memory Alloy

✅ Full Spectrum: Compression/Torsion/Tension Shapes + Custom Ends

✦ IATF 16949/ISO 13485 ✦ 24H Prototyping ✦ 37 Yrs Metal Memory DNA”

Product Presentation

Have you encountered any of these problems?

Elastic properties not up to standard

Function failure, equipment can not operate

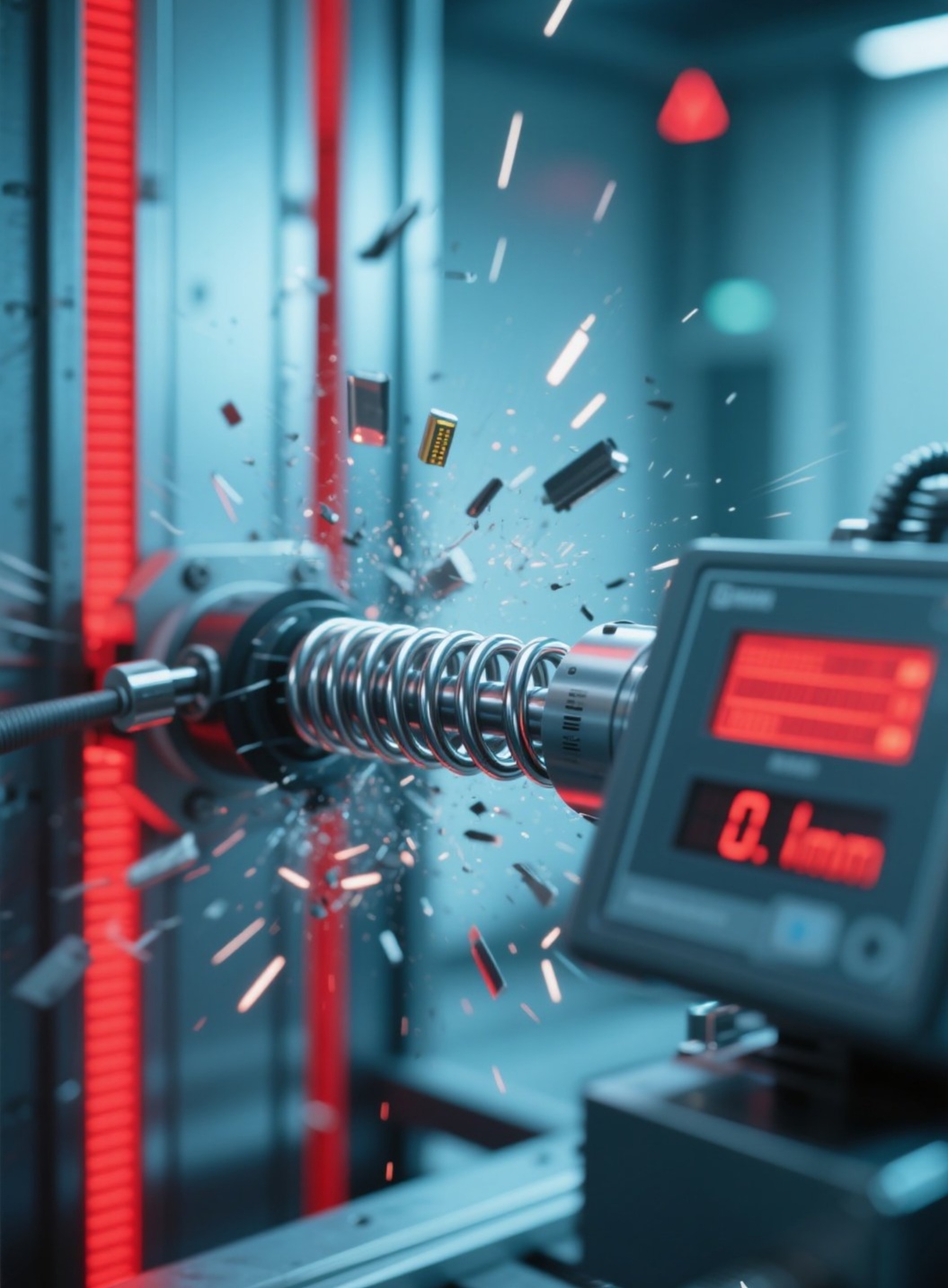

Insufficient Fatigue Life

High-frequency use, early fracture

The problem of dimensional accuracy

Assembly failure, parts conflict

Defects in surface quality

Surface defect, quality in question

Poor adaptability to the Environment

Corrosion Rust, scrap replacement

Poor fit in Assembly

Components Collide, system crashes

Delay in delivery of goods

Mass production fluctuation, production line shutdown

The cost of customization is too high

The budget got out of control and the project was put on hold

Our solution

1. Special research on high temperature customization

High-end nickel alloy special supply, withstand 750 °c continuous operation

2. Over-frequency bearing pressure does not break

23 million times military-grade anti-fatigue, verticality 0.1 °

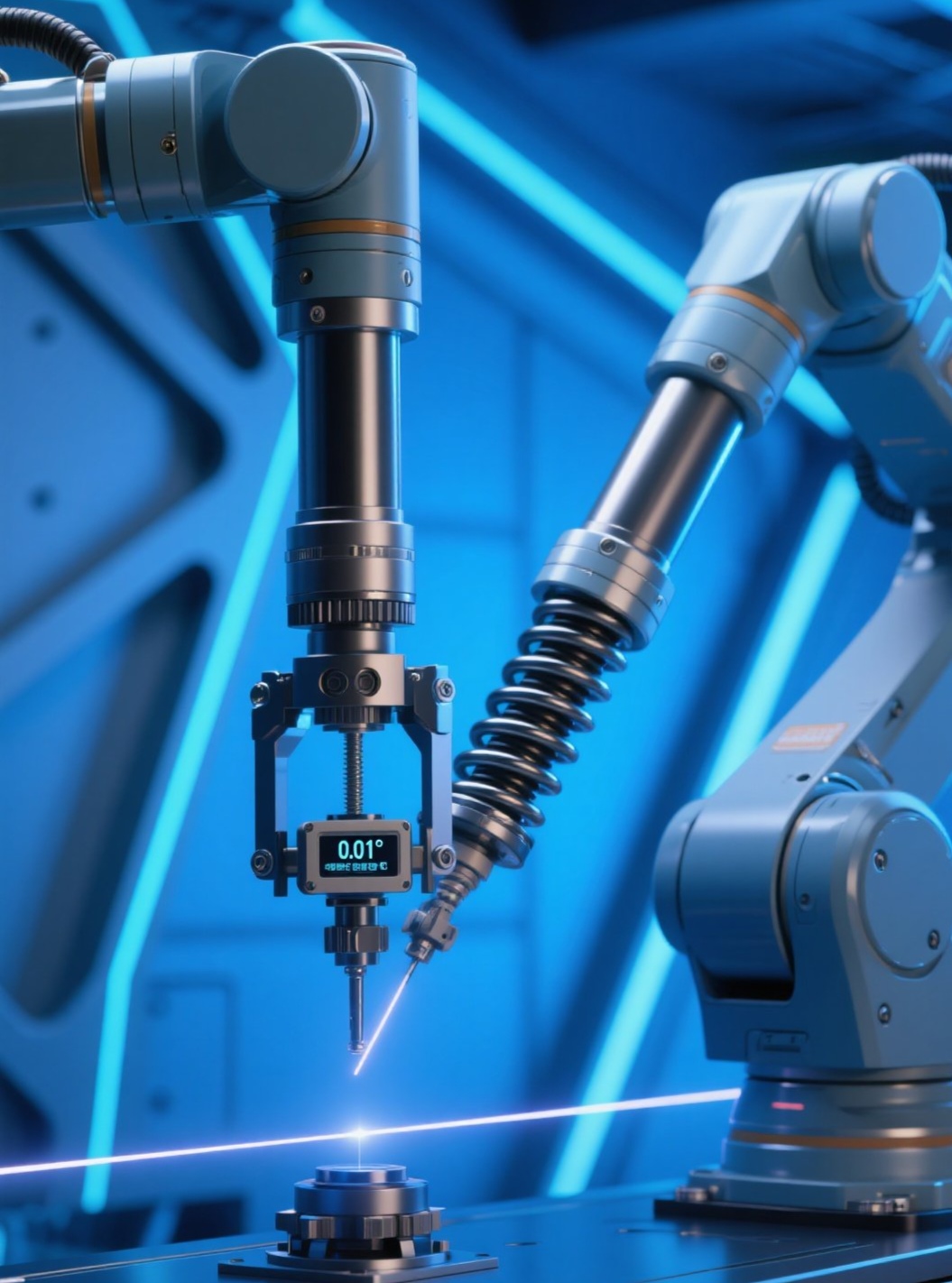

3. Micro Manufacturing Control

Full chain automation equipment, ± 0.01 mm zero deviation

Customize the solution according to your needs?

Why Us?

Precise reset control

Ensure zero error of component movement

End of vibration program

Reduces impact by 90% and doubles equipment life

Instant Power Engine

0.1 second charge release, violent output

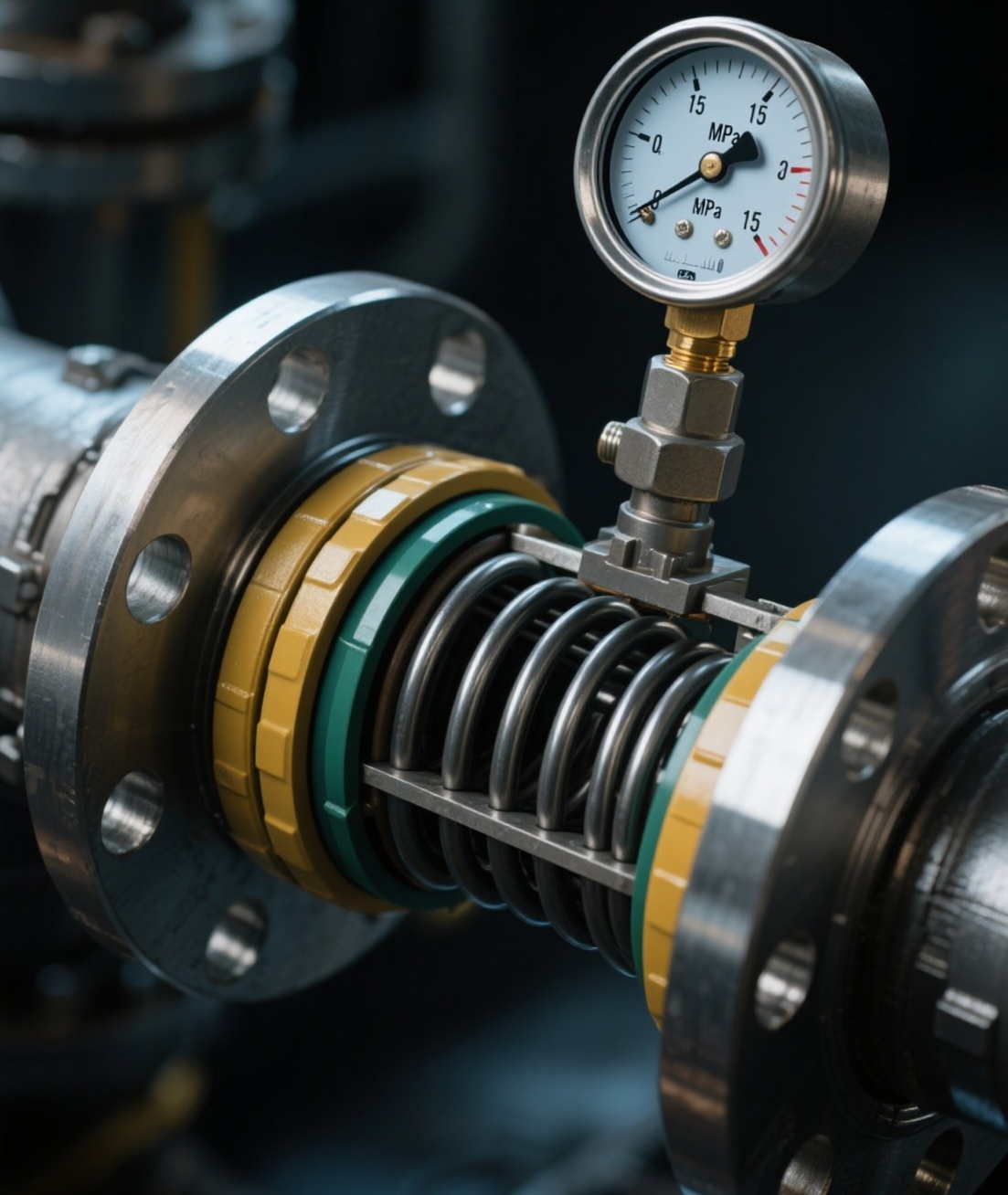

Specialist in constant pressure seals

Wear-resistant deformation, permanent on-line pressure

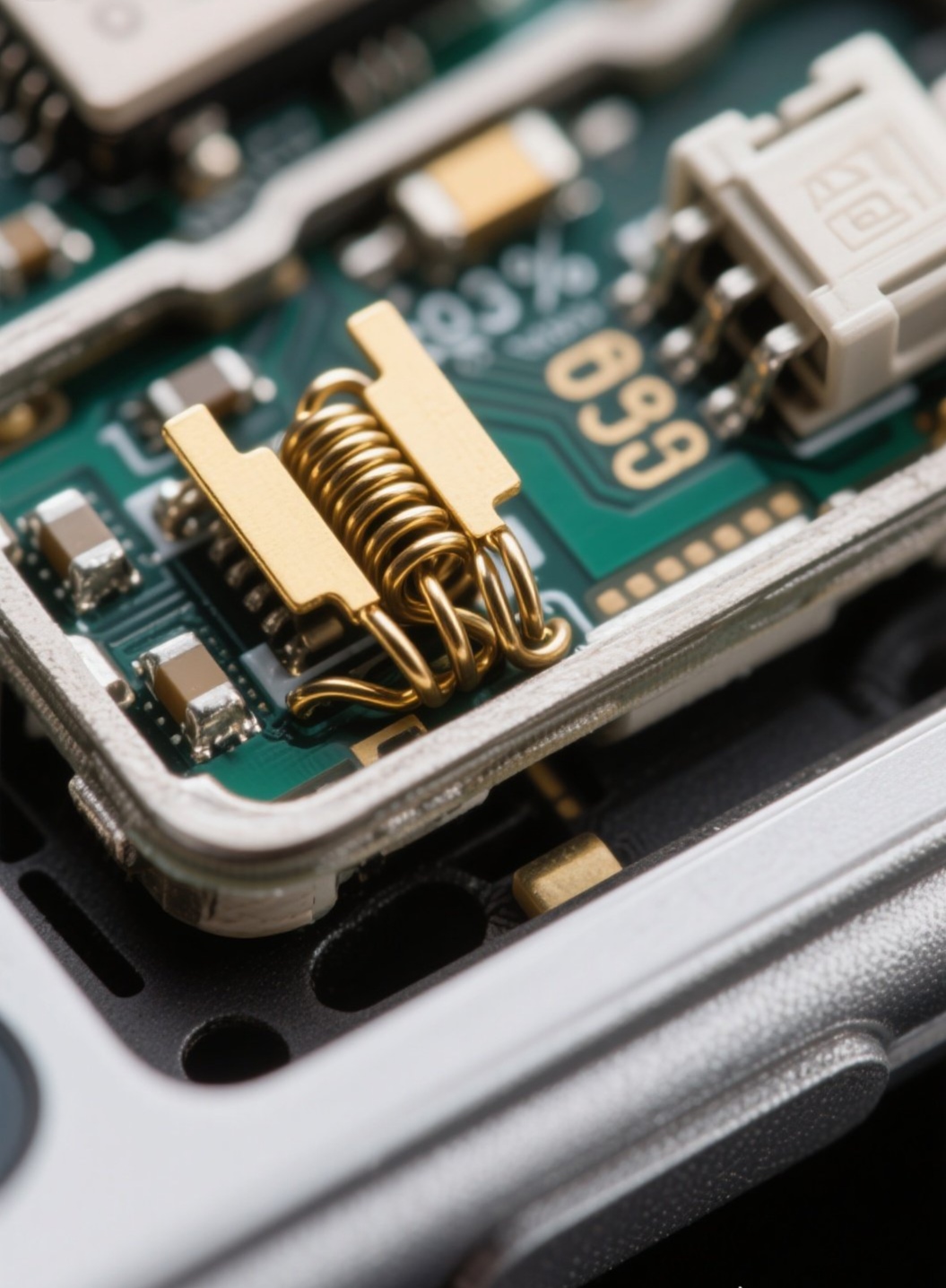

Micro-space Conqueror

Millimeter grade spring is inserted into the needle point position

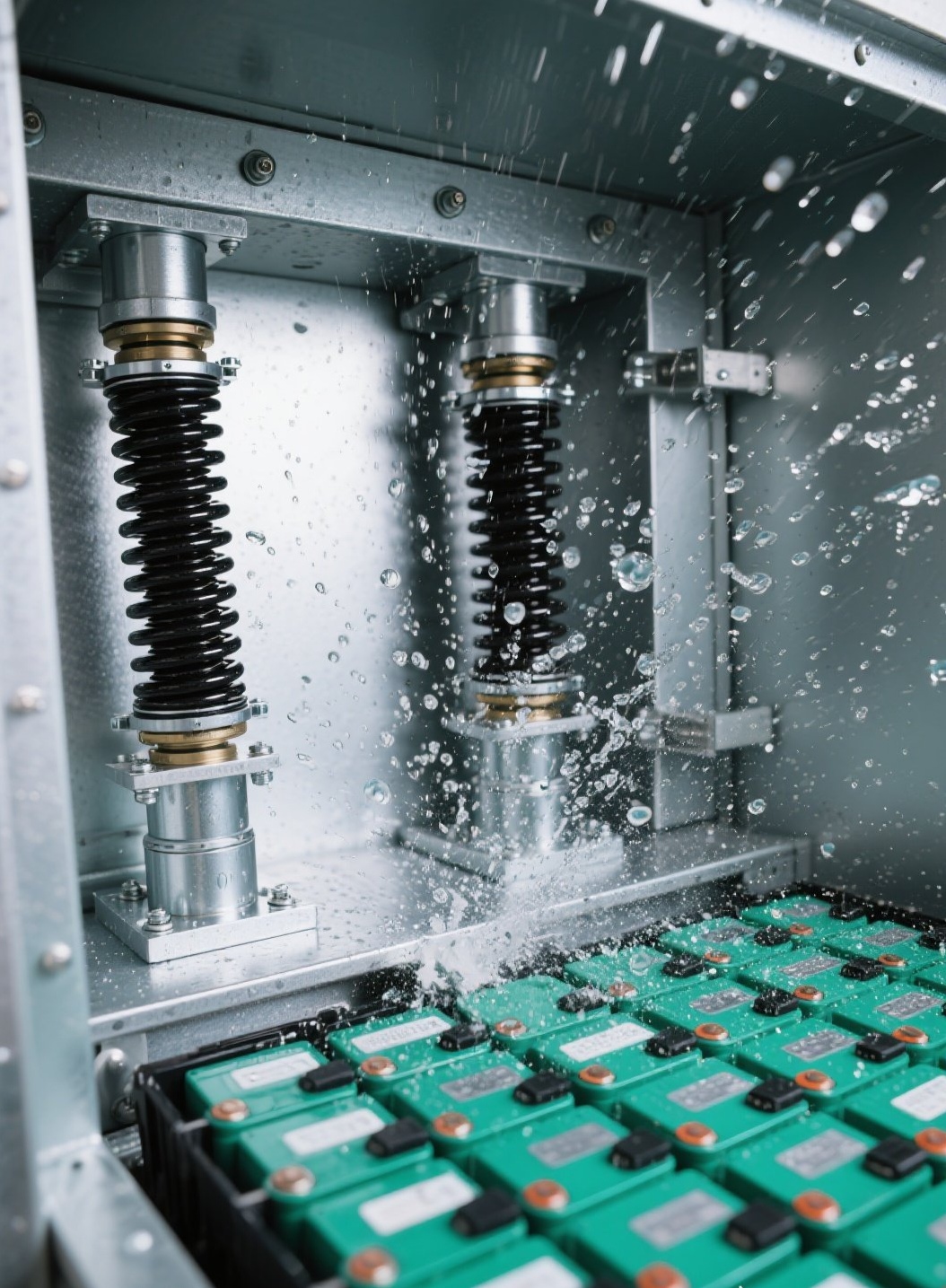

The Guardian of extreme environment

Under 750 °C + SALT SPRAY, its life is 3 times longer than that of its counterparts

Reconstruction of efficiency and cost

10 times more durable than rubber pads and 50% cheaper

Innovation Breakthrough Engine

Non-standard spring customization, so that mass production is impossible

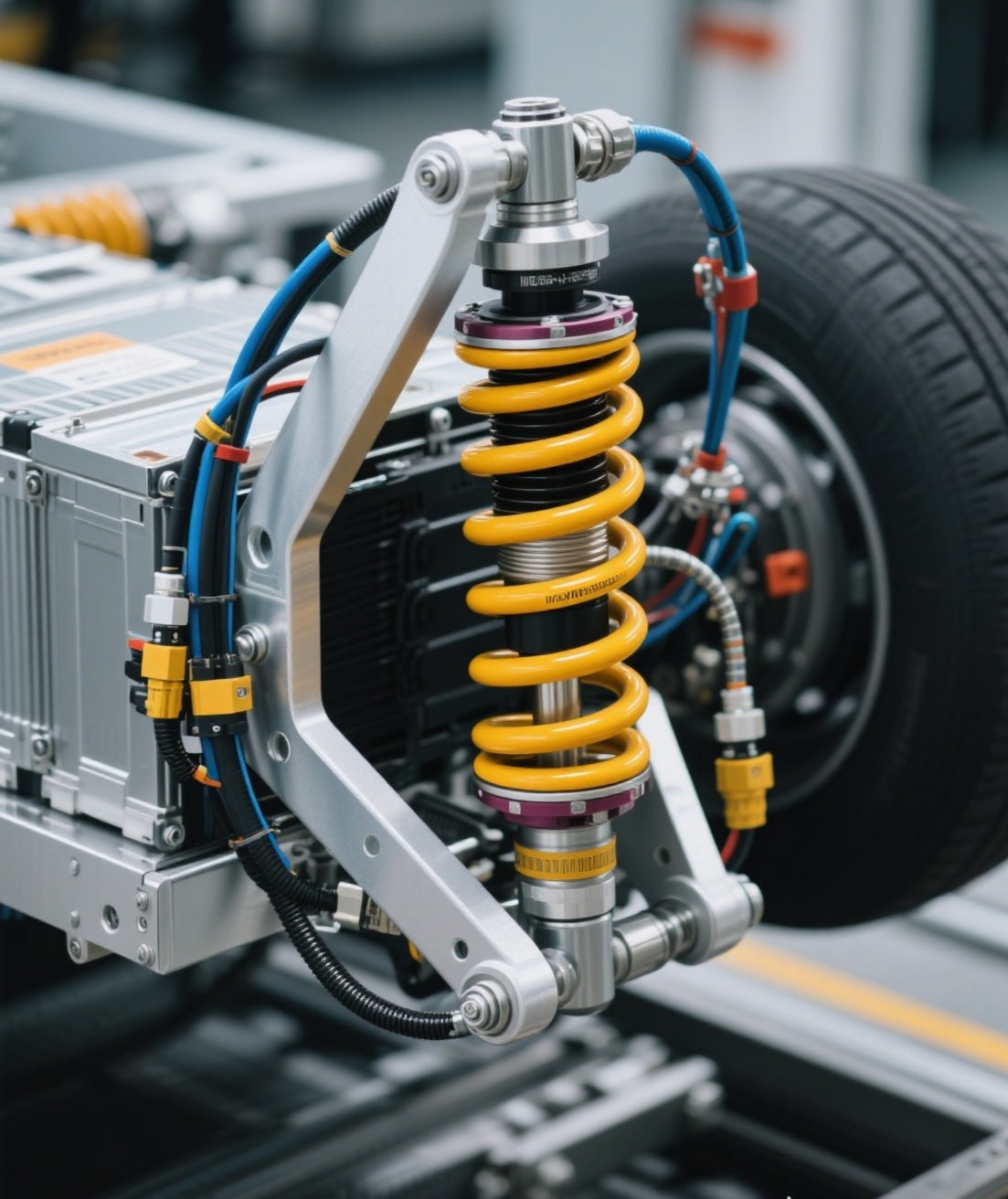

Areas of application

Car safety system

Medical precision transmission

Electric Pile Energy Storage Revolution

Mechanical joint with heavy load

Electronic Micro Force sensing

Power tendons for robots

Toughness of sports equipment

Transmission elasticity of wafer

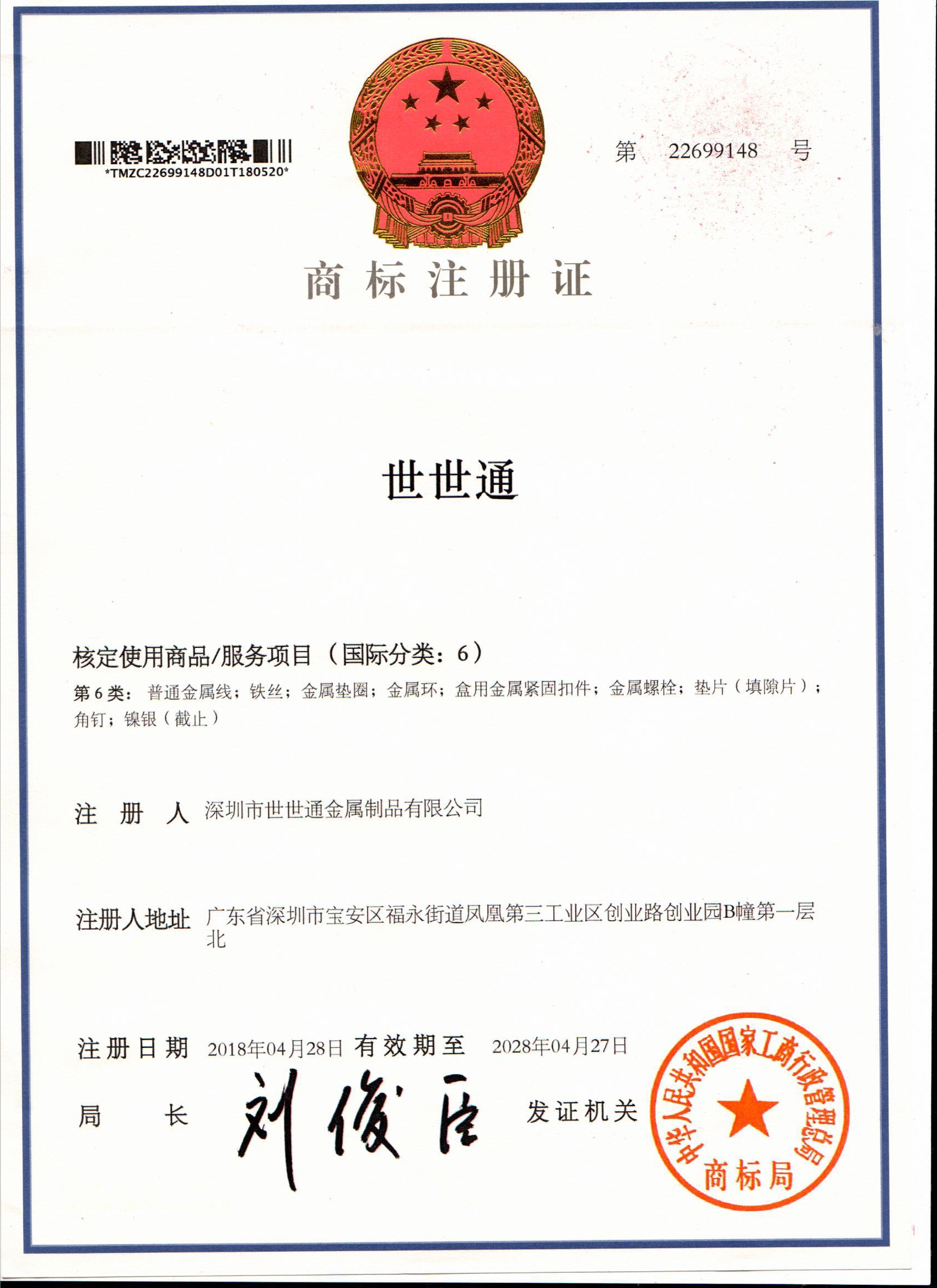

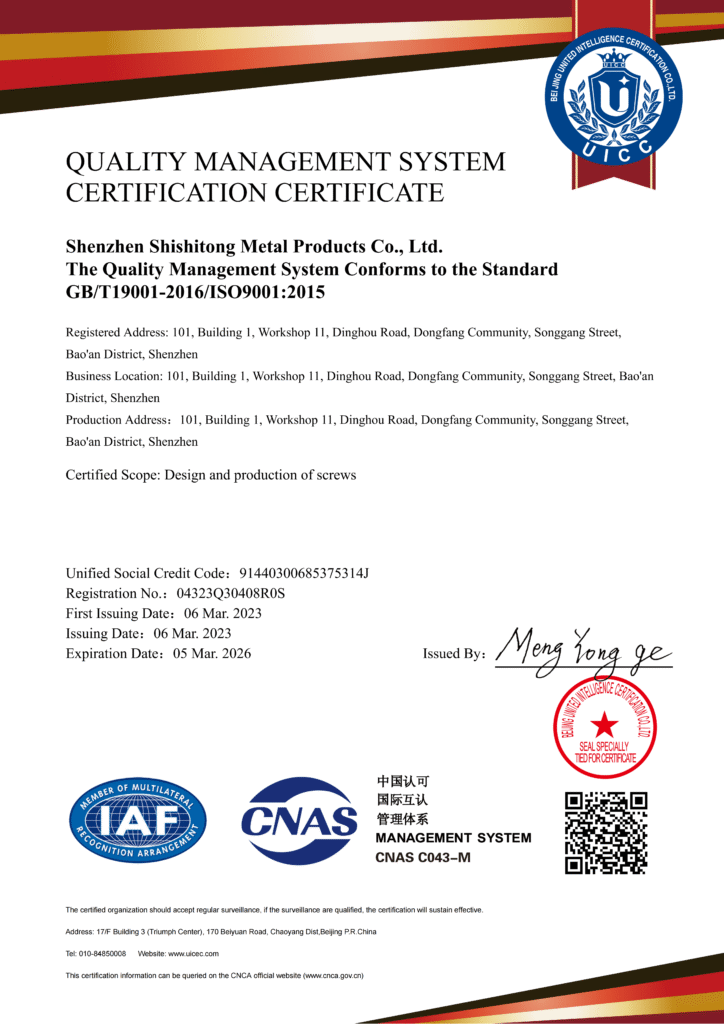

Our certificate

Our Happy Clients!

Customize the process

01

Need to know

30 minutes to lock the parameters of precision standards, Wire diameter/number of turns/elasticity value, environmental requirements dialysis

02

Scheme intelligence

36 years of expert optimization of anti-fracture design, Avoid fatigue failure, save 30% cost according to the evidence

03

The offer is very fast

10-minute accurate measurement of the elastic curve, material/process/batch cost one-click transparency

04

Agile start-up

Whole chain self-operated 24-hour rush order on the machine, titanium Wire/die/surface treatment within 7 days

05

Closed loop of quality control

Three-layer detection error ± 0.01 mm, The 1000h life test of salt spray was completed synchronously

06

No worries about delivery

The inspection report is shipped through the world, traceability of military packaging for anti-vibration and anti-rust

Frequently Asked Questions

Military grade quality control: ± 0.01 mm laser detector full inspection + salt spray 300h test report with goods

Ten-year life commitment: 17-4PH material fatigue test > 1 million times (2 times higher than the industry)

Rejection scenario: elastic error > 5% , surface burr visible to the naked eyeーー directly scrap heavy production

Lightning channel:

Small batch (≤10,000 pieces) shipped in 72 hours (7 days for peers)

Expediting charge is 0: before 18:00 on the same day the order will be on the machine (exclusive contract customers)

Extreme case study:

Diameter 0.2 mm microspring (for electronic wafer) yield 98%

TC4 titanium alloy + micro-arc oxidation salt spray 1000h (medical implant grade)

Cold heading with 30 times deformation of snake shaped spring (saving 40% of turning cost)

Triple certification penetration:

1. ISO 9001(serial number can be found on the official website)

2. IATF16949 automotive grade system (for new energy cooperative enterprises only)

3. fdareach Biocompatibility report (customs clearance for medical customers)

Cost transparency formula:

Total Price = (titanium wire grams × $30) + (CNC hours × $80) + salt spray test $50

Trump card:

From 300,000 pieces: return mold fee (up to 5000)

Annual Collection of 5000000: Free Upgrade Military Rust-proof packaging